Application of linear motors in machine tool industry

Key technology application

01

Weak points of traditional machine tools: The transmission chain passes through many transmission links from the motor as a power source to the work parts, which produces significant elastic deformation, backlash, movement lag, friction, vibration, noise and wear, etc.

02

Market demand: With the development of the industry, the demand for precision and high-speed processing of CNC machine tools continues to increase. The development trend of machine tools is towards high precision, high speed, composite, intelligence and environmental protection. .

Benefits of apps

01

Growing technological maturity

02

Universal application, great prospects for industrialization

03

Costs continue to fall and cost performance is higher

Capturing the high-end machine tool market with both opportunities and technology

01

Compared with the domestic research and development and application of overseas linear motor drive control technology, regardless of the performance and variety of products, the application of machine tools is in still in its infancy and there are even many gaps.

02

China is currently in a critical period of transformation and upgrading of intelligent manufacturing. The direct drive industry is expected to seize this great opportunity and achieve technological breakthroughs.

03

In practical applications, we continuously improve the design, explore processing techniques, improve the application level of linear motors in the industry, provide customers with comprehensive machine services and technical installation, gradually realize industrialization and occupy the important heights of the national high-end. CNC machine tools.

Comparison of transmission mechanisms

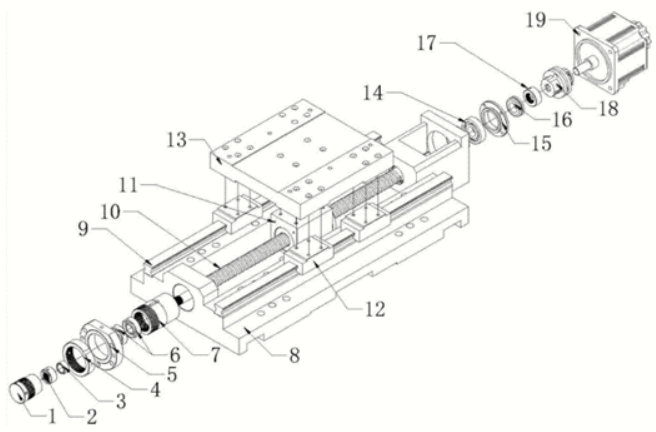

Traditional servo + screw machine tool structure

• The transmission structure is complex and the number of parts is large

• High installation accuracy requirements, longer installation time and low production efficiency

• Numerous transmission links and high precision error

• The mechanical transmission has numerous friction links

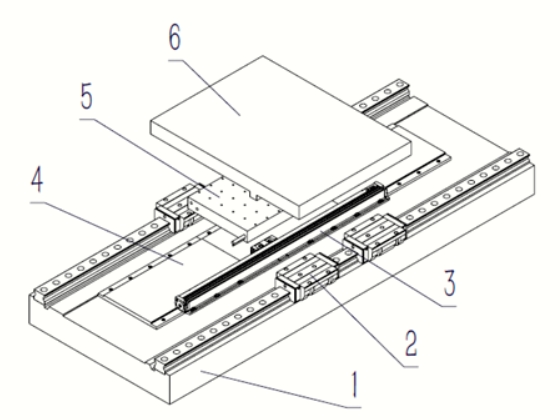

Direct Drive Motor Machine Tool Structure

•Simple structure and few parts

• The installation accuracy requirements of the linear motor only concern the air gap value and basic symmetry requirements, and the installation time is short.

•No intermediate transmission links

•No contact, no friction

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.