Currently, 3D printing of casting sand molds is mainly based on micro-binder jet (3DP) 3D printing technology. The binder used is mainly furan resin. However, furan resin sand molds are fragile, and the produced sand molds have poor high temperature resistance. and elastic, and are not very durable. They are suitable for the production of steel castings.[3]. Through years of continuous iterative innovation, research and development, Crystal Ceramics Technology has independently developed a modified resol phenolic resin for 3DP injection into sand molds based on continuous research on material modification in green resin. It is widely used in the production of cast steel casting. cast iron and non-ferrous metals.

![]() 1 Characteristics and performance parameters of modified phenolic resol resin for 3DP injection into sand mold

1 Characteristics and performance parameters of modified phenolic resol resin for 3DP injection into sand mold

1.1 Acid-cured modified resol phenolic resin

Binders used in 3DP sand printing are typically developed from self-curing sand resins. The resins used for self-hardening sand in the foundry industry mainly include: furan resin, acid-cured resol phenolic resin and grease-cured resol phenolic resin. Resins (alkali-phenolic resins) and amine-cured urethane resins[4]. At present, the main binder for 3DP injection into sand molds is furan resin. The sand 3D printing resin described in this article is developed from environmentally friendly acid-cured modified Class A resin and has the following series of characteristics[5-7]:

1) The added amount of resin is small, the curing speed can be adjusted flexibly, and the strength is equivalent to that of furan resin;

2) It is environmentally friendly, has no pungent or eye-irritating odor during modeling, and has very little odor after pouring;

3) It has the characteristics of resol phenolic resin and has secondary curing characteristics after being heated;

4) It has good disintegration properties after casting, comparable to furan resin;

5) Old sand after casting can be regenerated using level 2 mechanical process. The regeneration rate of silica sand can reach more than 95%, and that of orb sand and ceramsite sand can reach more than 98%. weak.

1.2 Characteristics and related performance parameters of modified resol phenolic resin for 3DP printing with sand mold

1.2.1 Process requirements of 3DP printing technology with sand mold

The working principle of 3DP printing with sand mold is as follows: firstly, the sand spreader spreads a layer of molding sand mixed with curing agent to a certain thickness, and then uses a nozzle to spray resin on the area to be molded to let the molding sand bind together to form a cross section of sand mold, then the lifting platform is lowered layer, the sand spreader spreads the sand again and the nozzle continues to spray and print in this way, the sand accumulates layer by layer. to get the sand model.[8]。

Compared with traditional casting molding, the 3DP sand casting process is divided into several processes: sand laying, inkjet printing, sand mold ejection and sand mold cleaning. Each process has its own technical requirements and difficulties:

1) The sand laying process requires that the molding sand has good fluidity, and the viscosity and addition ratio of the curing agent should be appropriate;

2) For an inkjet print head to eject resin normally and stably, on the one hand, the nozzle must not be clogged or opened by the glue, and on the other hand, the viscosity, surface tension and other performance parameters of the resin should be controlled within a certain range; the nozzle is a precision electronic device for printing. To ensure that it does not block the nozzle holes, the purity of the resin is very critical and the particle size of impurities must be controlled. be controlled at the micron scale;

3) Sand casting requires that the printed sand mold establish sufficient strength within a certain period of time and the resin can crosslink normally with a limited amount of curing agent to harden the sand mold;

4) Cleaning the sand mold requires less sand floating on the surface and easy cleaning. This requires that the resin that controls the boundary of the sand mold does not seep outward. The resin addition rate should not be too high, and the surface of the sand mold should be hardened. over time within a certain period of time.

1.2.2 Important performance parameters of 3D sand printing resin

Among the processes mentioned above, inkjet printing and sand laying are the two most critical processes of sand printing. For inkjet printing, sand 3D printing resin has the following key performance parameters:

1) Purity

The inkjet print head is the main component of 3D sand printing equipment[9]is a precision electronic device. The resin should not block the nozzle holes. This places strict requirements on the size of the impurity particles in the resin. Take the Starlight 1024LA model nozzle as an example, which is currently the most widely used in domestic sand printers, the volume of a single natural ink droplet is 80PL, and the diameter of the piezoelectric cavity and nozzle hole is of the order of a micron. In order to increase the life of the nozzle, it is necessary to avoid physical clogging of the nozzle and the purity of the resin ink should be maximized. Through a series of special processing processes, the maximum particle size of impurities in the resin can be less than 0.1μm~0.5μm. The laser diffraction method was used to detect and analyze the particle size of impurities in the 3D resin. The following figure shows the detection results:

Table 1 Impurity particle size distribution test results of sand mold 3D printing resin

▲Figure 1 Particle size distribution curve of impurity particles in sand 3D printing resin

2) Viscosity

Appropriate viscosity can ensure smooth circulation of ink in the ink circuit, which is beneficial to resin ejection and uniform ink droplet formation. If the viscosity is too low, the internal friction of the ink will be low and the droplets will be shaped like a meniscus, resulting in damped oscillation, which will affect the injection speed. In addition, liquids with too low a viscosity will have low damping and. will easily absorb air during high-frequency injection, and thus excessive droplets will be produced; the viscosity is too high, the ink fluidity is poor, and it is difficult to form small droplets. A larger excitation pulse amplitude is required and a higher amplitude. the power of the jet will cause vibration and cause mutual interference.[10]。

3) Surface tension

Proper surface tension can produce ideally shaped droplets to ensure uniform ink droplet formation, which can minimize droplets, and non-stick nozzles, which can minimize ink buildup on the nozzle plate and contribute to the smoothness of the inkjet.[10]。

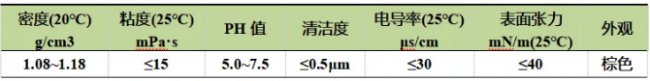

After years of experimentation and public relations, we have determined the resin-related performance parameters suitable for today’s consumer inkjet printheads and conducted real inkjet printing tests. The following table shows the relevant performance parameters of the modified resol phenolic resin for 3DP injection into the sand mold:

Table 2 Related performance parameters of 3D sand mold resin

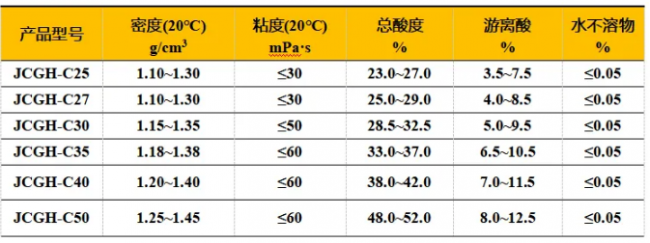

Table 3 Relevant performance parameters of special curing agent for 3D printing sand molds

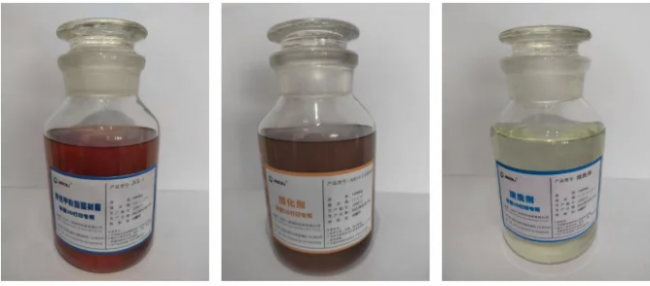

In addition to sand 3D printing resin and curing agent, our company has also developed a special cleaning agent for 3D inkjet printing. The main component is an environmentally friendly organic solvent. After high purity treatment, it guarantees the purity of the cleaning agent. reaches 0.1 ~ 0.5 microns, ensuring the purity of the cleaning agent after cleaning, there will be no secondary clogging and nozzle pollution. The picture below shows the sand 3D printing resin series products developed by our company:

In addition to sand 3D printing resin and curing agent, our company has also developed a special cleaning agent for 3D inkjet printing. The main component is an environmentally friendly organic solvent. After high purity treatment, it guarantees the purity of the cleaning agent. reaches 0.1 ~ 0.5 microns, ensuring the purity of the cleaning agent after cleaning, there will be no secondary clogging and nozzle pollution. The picture below shows the sand 3D printing resin series products developed by our company:

▲ Figure 2 3D printing resin series products with sand mold

▲ Figure 2 3D printing resin series products with sand mold

![]() 2 Practical application cases

2 Practical application cases

Jingci Technology’s 3D sand mold resin has been continuously printed on most common domestic printing equipment. This article uses the application case of Binglun intelligent molding workshop in Yantai, Shandong to illustrate. The company’s printing equipment is the 2500 series of a well-known domestic brand, using Gem model QE256-80 nozzles.

2.1 Test equipment

The casting sand uses 70/140 mesh silica sand supplied by Zhangwu Lianxin Jinrong Casting Materials Co., Ltd., and the resin binder uses our company’s modified resol phenolic resin. The curing agent is selected depending on the quality of the molding sand, ambient. temperature and humidity, and the C25 model is used.

2.2 Test methods

2.2.1 Inkjet test

Modified resole phenolic resin has lower viscosity than furan resin. In order to ensure that the nozzle ejects the resin continuously with ink, without losing frames, and the ink can be ejected normally and stably, the printing parameters should be adjusted in the following aspects. when printing on the machine:

1) Main negative pressure

For a nozzle to eject ink continuously and stably, the front end of the ink must be crescent-shaped. The main negative pressure exerted by the ink circuit system can cause the nozzle to produce a suitable meniscus liquid shape, while locking the ink to prevent the ink from continuously flowing out of the nozzle hole. The size of the main negative pressure is mainly related to the height difference between the liquid level of the main ink tank and the nozzle nozzle plate.[11]on the other hand, it must be refined according to the viscosity of the ink and the surface tension.

2) Waveform Settings

The inkjet print head used for 3D sand printing is a piezoelectric nozzle and the waveform parameters involved include pulse voltage, pulse width, firing frequency and the pulse wave number (single or double wave). On the one hand, the setting of waveform parameters is linked to the state of the nozzle. On the other hand, it should be adjusted appropriately according to the viscosity and surface tension of the resin. Generally, viscosity and surface tension of liquids appear. a decreasing trend as temperature increases. After the viscosity is reduced, the voltage and pulse width can be reduced appropriately, and the number of pulse waves can be adjusted to a single wave according to the state of the nozzle.

The image below shows the inkjet printing test situation after the print settings are adjusted appropriately:

▲Figure 3 Inkjet printing test situation

▲Figure 3 Inkjet printing test situation

2.2.2 Relationship between the quantity of resin added and the resistance of the sand mold

After the printing parameters are adjusted, print on the machine, change the resin addition amount by adjusting the resolution, and test the strength of the sand mold under different addition amounts. Sand mold strength tested tensile strength and compressive strength. The “8” blocks for measuring tensile strength are arranged in three directions: X, Y and Z. The test results represent the sand mold in the X, Y and Z directions respectively intensity situation. The compressive strength test block is a cylinder with a size of Φ40×40. Table 4 shows the test results:

Table 4 Sand casting strength test results with different amounts of resin addition

According to the test results in Table 4, as the amount of resin added increases, the strength of the sand mold gradually increases. It is more suitable to control the resin addition amount between 1.8-2.0%, which can meet the modeling requirements.

The bonding between the micro-scale casting sand was observed by scanning electron microscope. The following figure shows the observation results:

▲Figure 4 Observation results of bonding conditions of sand molds

▲Figure 4 Observation results of bonding conditions of sand molds

It can be seen from the scanning electron microscope observation results in the figure above that the bonding bridges after the resin cross-linking reaction are filled with molding sand. The resin can penetrate and envelop the sand particles well, and a sufficient number of effective particles. connecting bridges can be built between the sand particles, thus establishing good resistance to the sand mold. In addition, there are many micropowder particles wrapped in resin films attached to the surface of sand grains and between sand grains, which also act as a connecting bridge between sand grains, which also improves the strength sand mold to a certain extent. extent.

2.2.3 Gas generation detection

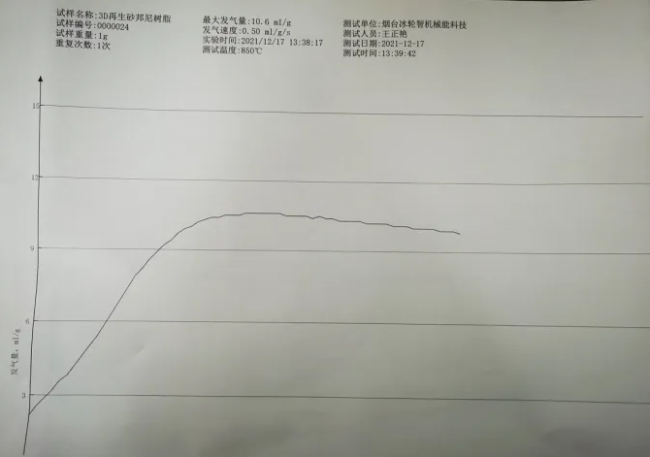

The gas generation tester was tested on the sand mold block with 2.0% resin addition. The picture below shows the gas generation tester in the sand laboratory.

▲ Figure 5 Casting sand laboratory gas generation tester and balance

▲ Figure 5 Casting sand laboratory gas generation tester and balance

The test results are as follows: the gas generation speed is 0.5ml/g/s and the maximum gas generation volume is 10.6ml/g. The image below shows the test report.

▲Figure 6 Sand mold gas generation test report

▲Figure 6 Sand mold gas generation test report

2.2.4 Actual production situation

Crystal Ceramics Technology Resin printed and produced on 2 printers for 5 consecutive months. Table 5 shows print production statistics:

Table 5 Batch Print Production Statistics

The average resin consumption over several months of printing in continuous production is 2.06%. Statistical consumption includes the amount of resin consumed by flash printing and ink pressing operations during the production shutdown period. The following is a printed-in-place casting sand mold.

▲Figure 8 The sand mold produced by printing

▲Figure 8 The sand mold produced by printing

▲Photo 9: Boxing finished and ready to pour

▲Photo 9: Boxing finished and ready to pour

The picture below shows the condition of the casting after shot peening. After pouring, the sand mold has good bendability and is easy to shake. There is no sticky sand in the casting, and the casting quality meets the requirements.

▲Figure 10 Castings after shot blasting

▲Figure 10 Castings after shot blasting

![]() 3 Conclusion

3 Conclusion

1) The modified phenolic resol resin used for 3DP injection of sand molds has the characteristics of good environmental protection, high sand mold strength, secondary curing, good pliability and a high recycling rate of old sand;

2) This 3D sand mold resin has high purity and suitable viscosity, surface tension and conductivity. It is suitable for different brands and models of nozzles. At the same time, curing agents with different acidity models have been developed to suit different grades. molding sand and various environmental temperatures.

3) 3D printing resin for sand molds has been applied in batch production in Yantai Binglun intelligent manufacturing workshop for a long time. The strength and gas generation of the sand mold can meet the casting production requirements, and the surface quality of the castings is good. .

References

[1]Huang Yaoguang. Aluminum alloy special-shaped communication tube casting practice based on 3D sand printing technology.[J].Special casting machine for non-ferrous alloys, 2021, 41 (5): 611-613;

[2]Ministry of Industry and Information Technology, National Development and Reform Commission, Ministry of Ecology and Environment. Guidance on promoting the high-quality development of the casting and forging industry. Ministry of Industry and Information Technology China Unicom Equipment.[2023]No. 40;

[3]Wang Yongen, Liu Yi, Zhou Pengju et al. Application of thermosetting phenolic resin in 3D printing sand mold casting.[J].China Foundry Equipment Technology, 2019, 54(6): 40-41;

[4]Li Chuanshi. New discussion on modeling materials.[M].Beijing: Machinery Industry Press, 1992: 256;

[5]Li Chuanshi. Application and development of self-hardening sand binders.[J].Proceedings of the 10th Annual Meeting of China Foundry Association, 2012: 851-858;

[6]Ma Jingzhong. The development of cast steel sand binders from the perspectives of environmental protection, energy saving and emission reduction.[J].Proceedings of the 10th Annual Meeting of the China Foundry Association, 2012: 104-116;

[7]Tang Shenglai, Wang Haijiang, Zou Xiaofeng Application case of Bonny resin sand production for steel castings.[J].Metal treatment (heat treatment), 2014, 9: 46-48;

[8]Liao Hong. Application of 3DP technology in the molding of complex compressor shells[J]. Foundry Engineering, 2022,6:64-67;

[9]Ma Liqiang, Wang Zhigang, Wang Junwei, et al. Research on Application of 3D Inkjet Sand Printing Head[J].

[10]Hu Jun, Ou Zhuokun, Guo Wusheng. A Brief Discussion on Ceramic Ink KPIs[J]. Foshan Ceramics, 2012,8(192):1-4;

[11]Ma Liqiang, Liu Yi et al. Application and research of ink circulation system in 3D sand printing[J]. Foundry Equipment and Processes, 8(4):47-49.

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.