Recently, Director Zhang Bin of the Orthopedic Hospital of the First Affiliated Hospital of Nanchang University led his elite team to operate on a patient with atlantoaxial dislocation and scoliosis through superb surgical techniques and rich clinical experience, and achieved good surgical results.

Case 1: Atlanto-axial dislocation

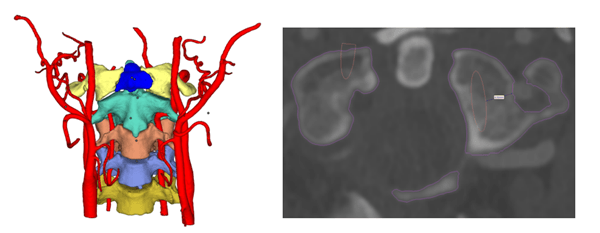

patient1The diagnosis was that of multiple fractures of the right occipital condyle, the anterior arch of the atlas and the base of the right transverse process and the odontoid process, and the free bone fragment of the anterior arch of the The atlas was slightly advanced.

△Three-dimensional reconstruction of the patient andCTReport

The human cervical vertebra is made up of7It is made up of vertebral bodies. The two upper vertebral bodies are the upper cervical vertebrae, namely the atlantoaxial vertebrae, which have a wide range of motion. The head connected to the cervical vertebrae is a large and heavy entity. When the head is subjected to an instantaneous violent impact, such as falling, bumping, smashing, etc., the head is displaced, or when the head is suddenly violently whipped by an external force, such as when the head is suddenly tilted forward during a violent movement. sudden braking, and when the head falls, If the head is thrown back suddenly, the upper cervical vertebrae located at the junction of the head and neck are extremely susceptible to injury, such as odontoid fractures, rupture of the transverse ligament of the atlases, etc. If correct diagnosis and treatment are not obtained at an early stage, atlantoaxial dislocation will occur at a later stage. The mechanisms of injury of clinically common atlantoaxial subluxation mostly fall into this category.

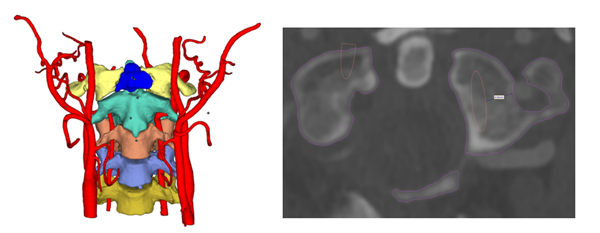

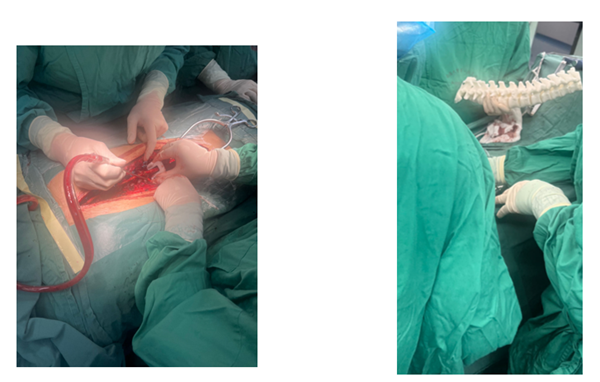

△Intraoperative photos and postoperative photosCTrendered

When performing pedicle screw implantation surgery, the Atlantoaxial Screw Placement Guide Plate provided by the Digital Medicine Center should be used according to the preoperative instructions.CTCheck the provided image data, adjust the angle of the pedicle abduction angle and the sagittal angle of the spinal canal axis according to the angle of the pedicle abduction angle and the sagittal angle, drill through the opening and detect the drill bit with a probe. the holes are correct, the pedicle screws can be placed. The aimer is easy to use and can accurately position the implantation angle of spinal root screws.

Case 2: Scoliosis

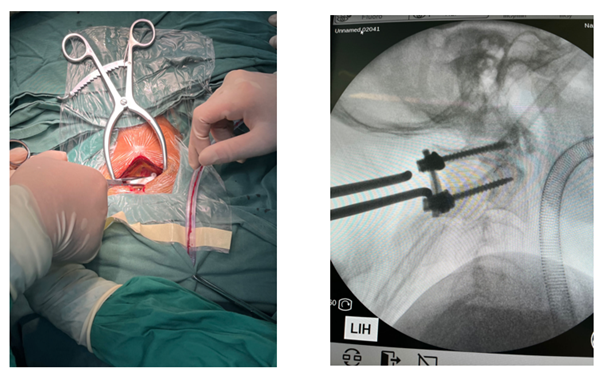

patient2,CTIndicates scoliotic deformity.

△3D reconstruction of the patient

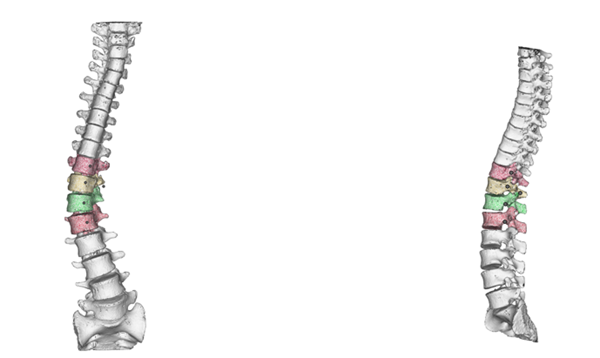

Scoliosis refers to one or more segments of the spine that curve laterally relative to the midline of the body in the coronal plane, forming a curvature of the spinal deformity, which is usually accompanied by rotation of the spine and a posterior or anterior projection in the sagittal plane. There is an increase or decrease in the process, as well as rotational tilt deformity of the ribs and pelvis and abnormalities of the paravertebral ligaments and muscles. During the operation, director Zhang Bin and his team used their rich clinical experience to place the screws and realign them, thereby restoring the spine to its normal angle.

△Intraoperative photos

The pedicle screw navigation model can help doctors plan the surgical route and guide implant implantation more accurately during spinal internal fixation surgery. For the aiming accuracy of the precision sight, it is based on the anatomy of the vertebrae,3DPrinting of molding characteristics and nail placement surgery status,The structure of the viewfinder is designed to closely adapt to the dissection state of the vertebrae during surgery.;Determine the target surface as the contours of the target vertebra and adjacent vertebrae, the back of the transverse process, and the dorsal aspect of the root of the spinous process.;The aiming device is designed to avoid interference with the superior articular process, the transverse process of the target vertebra, and the spinous process of adjacent vertebrae.;The sights all meet the positioning accuracy requirements.,And the acupressure surface with non-slip edges is more comfortable,The nail installation process is not subject to vibration and slippage.

3DIntroduction to Dental Appliance Printing

After completing the initial surgery, subsequent recovery is equally important. Also available at the Center for Digital Medicine“Custom made”3DPrinted orthodontic appliances cooperate with doctors to achieve better postoperative recovery.

△A photo of the actual support device

1、3DPrinting orthopedic devices facilitates the precise reduction and fixation of limb fractures, reduces the number of surgical procedures, and promotes improvement and simplification of the treatment of spinal deformities in children requiring continuous external fixation ;

2Significantly improve patient comfort, personalized customization, perfect fit, breathable and lightweight, non-irritating, non-allergic, reducing patient pain, can be repeatedly put on and taken off, waterproof, convenient for patients to take care of themselves -themselves in daily life;

3Greatly improve the efficiency of medical care work, fully automatic intelligent processing, simple operation, no contact between doctors and patients, patient participation time is less than one minute, greatly reducing the work intensity of medical staff and reducing the time for patient diagnosis and treatment, there are few clinical contraindications and the difficulty of care is reduced;

4degradable, strong and lightweight polymer biomaterial (the weight is only one-sixth that of gypsum in the same volume, and the strength is 1/6 that of gypsum)20times), colorless, odorless, non-irritating, completely degradable and meets environmental protection requirements.XRays do not produce artifacts and do not affect inspection;

5fills the fixed gap after surgery, automatic opening design, effectively avoids the patient’s wound, does not affect the dressing change and wound treatment, and improves the healing rate.

source:NTU One Digital Medicine 3D Printing Medicine-Industry Interaction

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.