Recently, according to Mohou.com, led by researchers from Lawrence Berkeley National Laboratory and Oak Ridge National Laboratory in the United States, the relevant research work was announced on December 2, 2022 as “Outstanding Fracture Toughness of Based Materials of medium and high strength CrCoNi. – Entropy Alloys at 20 Kelvin” was published in the leading international journal “Science”. This invention relates to medium entropy CrCoNi alloys and high entropy alloys having excellent fracture toughness. When designing structural materials, they must be strong while being ductile and resistant to fracture. It is often a compromise between these properties. But this CrCoNi material is the. two, and instead of becoming brittle at low temperatures, it becomes stronger.

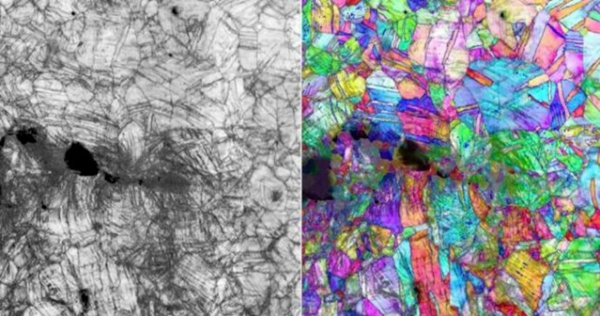

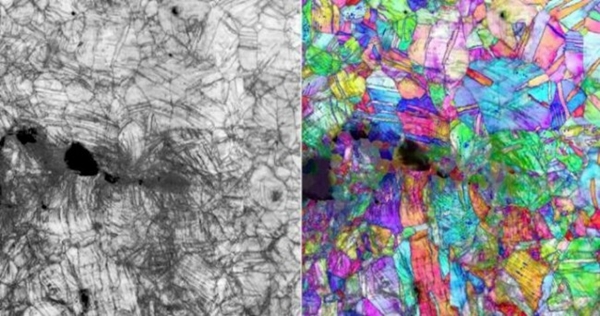

Microscopically generated images showing the fracture path and accompanying nanoscale crystal structure deformation of CrCoNi alloy during stress testing at 20 Kelvin (-424 F). The crack extends from left to right. © Oak Ridge National Laboratory

Highest toughness ever seen

Scientists studying a metal alloy composed of chromium, cobalt and nickel (CrCoNi) have measured the highest toughness ever achieved. Not only is this metal extremely malleable. In materials science, this means a high degree of ductility and also very high strength, that is, it resists permanent deformation. Its strength and ductility increase with decreasing temperature, unlike most other existing materials.

HEA has been a popular area of research since its development nearly 20 years ago, but the technology needed to push materials to their limits in extreme testing has only recently emerged. According to the article “(1) Advantages and Disadvantages of 3D Printing Technology l 3D Printed HEA High Entropy Alloys: Examination of Microstructure and Properties” in 3D Science Valley, high entropy alloys (HEA) are promising multi-component alloys with a unique new combination of microstructure and excellent properties. However, there are still some limitations to the manufacture of HEA by traditional methods. HEA manufactured by 3D printing has optimized microstructure and improved performance, and the application of additive manufacturing (AM) technology in HEA production has shown a significant growth trend in recent years.

© 3D Science Valley white paper

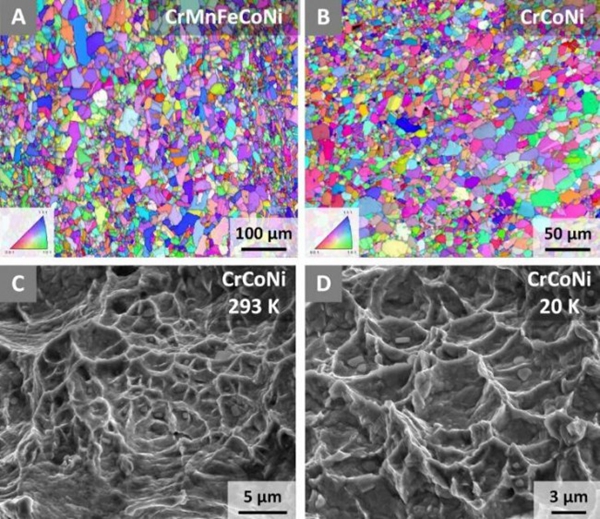

Fracture toughness values for equivalent alloys CrCoNi and CrMnFeCoNi at 20 Kelvin (K). The crack initiation fracture toughness of CrMnFeCoNi and CrCoNi was found to be particularly high, 262 and 459 MPa.m½ respectively; CrCoNi showed a crack growth toughness exceeding 540 MPa.m½ after a stable crack of 2.25 mm; The deformation structure of the crack tip at 20 K is completely different from that at higher temperatures. They include stacking faults, fine nanotwins, and nucleation and confined growth of transformed ε martensite, with coherent interfaces that promote dislocation arrest and transport to produce strength and ductility. They believe that these alloys develop fracture toughness through a progressive synergy of deformation mechanisms, dislocation slip, stacking fault formation, nanotwins, and phase transformations that combine to prolong work hardening while increasing strength and ductility, resulting in excellent toughness.

The perfect combination of strength and toughness

Despite their extremely high toughness, these alloys do not exhibit complex microstructures because they are simple single-phase solid solutions. An important question therefore is the origin of this particular breaking strength and why it increases so gradually at low temperatures.

To address this issue, researchers have studied the cooperative behavior of plastic deformation defects in these alloys, primarily using CrCoNi alloys to illustrate typical behavior at 20K versus room temperature. Post-fracture EBSD analysis and high-resolution transmission electron microscopy (HRTEM) were used to observe areas of severe deformation in the plastic zone, directly adjacent to the crack tip, where local strains can easily reach 60 to 100%. While the microstructure begins as a fairly simple single-phase solid solution, deformation at 20 K transforms the structure into a rich and complex mixture of phases and defective structures.

About ten years ago, researchers began experimenting with CrCoNi and another alloy that also contained manganese and iron, called CrMnFeCoNi. They made samples of the alloy, then lowered the material to liquid nitrogen temperatures (about 77 Kelvin, or minus 321 degrees Fahrenheit) and discovered impressive strength and toughness. The researchers continued their tests in the temperature range of liquid helium, and fortunately, the results were worth the effort.

These images, generated by scanning electron microscopy, show the grain structure and lattice orientation of (A) CrMnFeCoNi and (B) CrCoNi alloys. (C) and (D) show examples of CrCoNi fracture at 293 K and 20 K, respectively.© Berkeley Laboratory

Many solid substances, including metals, exist in crystalline form, characterized by repeating 3D patterns of atoms, called unit cells, which make up larger structures, called lattices. The strength and toughness of a material come from the physical properties of its crystal lattice. No crystal is perfect, which is why the unit cells of a material inevitably contain “defects”, a prominent example being dislocations: the boundaries where the undeformed lattice meets the deformed lattice. When a force is applied to a material – think of bending a metal spoon, for example – the change in shape is achieved by the movement of dislocations in the crystal lattice. The more easily the dislocations move, the softer the material. But if the movement of a dislocation is blocked by an obstacle in the form of lattice irregularities, then more force is required to move the atoms inside the dislocation and the material becomes stronger. On the other hand, obstacles often make the material more brittle or susceptible to cracking.

Rethink physical characteristics and performance

The research team’s new findings, along with other recent work on HEA, could force the materials science community to reconsider long-held ideas about how physical properties drive performance. Because metallurgists say that the structure of a material determines its properties, while the structure of NiCoCr is the simplest imaginable. However, when it deforms, the structure becomes very complex, and this transformation helps explain its extraordinary resistance to rupture. According to a UC Berkeley professor of materials science and engineering, the industry is experiencing this unexpected shift thanks to the development of fast electron detectors in electron microscopes, which allow researchers to distinguish between different types of crystals and resolve them at the nanoscale. in them, they are only a few atoms wide.

This research was supported by the Department of Energy’s Office of Science. Cryogenic mechanical testing and neutron diffraction were performed at the Rutherford Appleton Laboratory. Microscopic analyzes were performed at the National Molecular Foundry Electron Microscopy Center, among other facilities, including the DOE Office of Science at Berkeley Lab.

Source: 3D Science Valley

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.