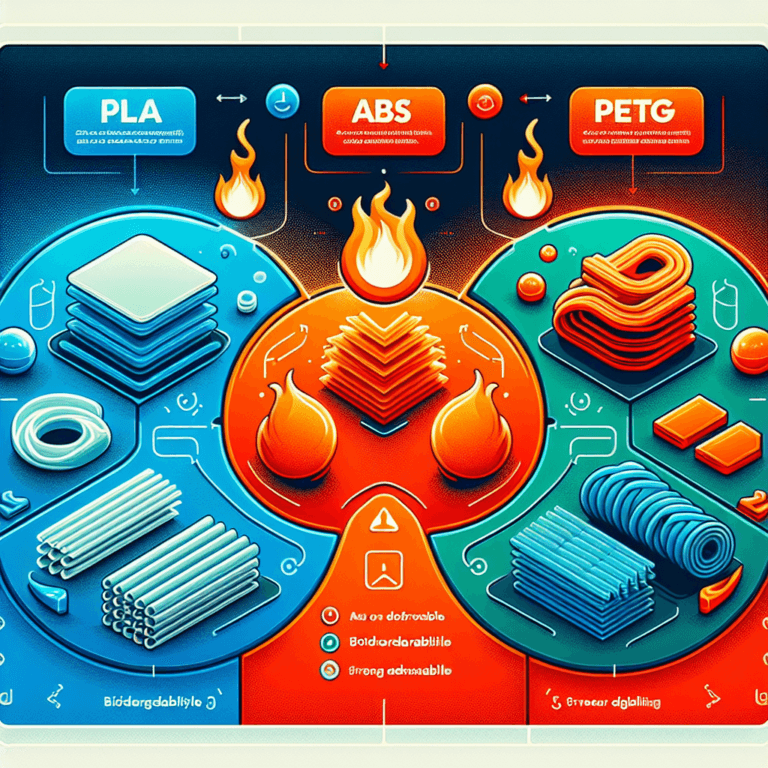

When it comes to 3D printing, selecting the right filament is crucial for achieving the desired results. Among the leading materials available in the market, PLA, ABS, and PETG stand out as popular choices, each bringing unique characteristics and advantages to the table. This blog post delves into the primary differences between these three filaments, helping you make an informed choice for your next project.

PLA: The Popular Choice

What is PLA?

Polylactic Acid, commonly known as PLA, is a biodegradable thermoplastic derived from renewable resources like corn starch or sugarcane. This eco-friendly characteristic has contributed to its rapid rise in popularity, especially among beginners in the 3D printing community.

Characteristics of PLA

Ease of Use: PLA is known for its user-friendly nature. It has a low melting point, which means it can be printed at relatively low temperatures (around 190–220°C). This feature makes it compatible with a wider range of 3D printers and reduces the risk of warping, which is a common issue with other materials.

Surface Finish: PLA typically produces prints with a high-quality surface finish. The final product can exhibit a smooth and glossy appearance, often requiring minimal post-processing. This makes PLA an excellent choice for aesthetic models, prototypes, and decorative items.

- Biodegradability: One of PLA’s standout features is its biodegradability. Since it is derived from natural sources, it can decompose under the right conditions, making it a more environmentally friendly option compared to other plastics.

Limitations of PLA

While PLA has numerous strengths, it does have a few limitations:

Heat Resistance: PLA is not very heat resistant, softening at temperatures above 60°C. This makes it less suitable for applications requiring high thermal stability.

- Durability: Although PLA can produce aesthetically pleasing prints, it is more brittle compared to other materials. This brittleness can lead to cracking or breaking under stress.

Best Uses for PLA

Given its properties, PLA is ideal for:

- Prototyping

- Decorative items

- Custom figurines

- Low-stress functional parts

ABS: The Tough Contender

What is ABS?

Acrylonitrile Butadiene Styrene (ABS) is a petroleum-based thermoplastic known for its strength and durability. It’s the filament of choice for many professional and industrial applications due to its robust nature.

Characteristics of ABS

Strength and Durability: ABS is highly prized for its toughness and resilience. It can withstand significant impact and stress, making it suitable for functional parts and mechanical components.

Heat Resistance: ABS performs better under high temperatures, with a glass transition temperature around 105°C. This makes it an excellent option for parts exposed to heat, such as automotive components and kitchen items.

- Post-Processing Potential: ABS can be easily sanded and painted, allowing for additional post-processing to improve the final appearance of prints. Moreover, it can be smoothed using acetone vapor, resulting in a glossy finish.

Limitations of ABS

While ABS boasts excellent mechanical properties, it isn’t without its drawbacks:

Odor: Printing with ABS can produce strong fumes and odors due to its petroleum-based nature. It’s crucial to ensure proper ventilation when using this filament.

- Warping: ABS is prone to warping, especially when printed on non-heated surfaces. To mitigate this issue, heated print beds and enclosures are recommended.

Best Uses for ABS

ABS is well-suited for projects that demand toughness and durability, such as:

- Functional prototypes

- Mechanical parts

- Automotive components

- Toys and models

PETG: The Versatile Hybrid

What is PETG?

Polyethylene Terephthalate Glycol-modified (PETG) combines the properties of both PLA and ABS. It is a glycol-modified variant of PET, widely used in consumer products and packaging.

Characteristics of PETG

Balance of Properties: PETG offers an excellent balance between strength, flexibility, and ease of printing. It is more robust than PLA while maintaining printability close to that of PLA.

Chemical Resistance: One of PETG’s notable features is its resistance to chemicals and moisture, making it suitable for applications where durability and exposure to harsh substances are concerns.

- Low Warping: PETG exhibits minimal warping during printing, which significantly simplifies the printing process. This characteristic is advantageous for creating large parts or complex geometries.

Limitations of PETG

Despite its versatility, PETG does have some limitations:

Stringing: PETG is prone to stringing, leading to unwanted fine strands of filament between parts. Proper retraction settings can help mitigate this issue.

- Surface Finish: While PETG can produce quality prints, it doesn’t offer the same level of aesthetic finish as PLA or the post-processing ability of ABS.

Best Uses for PETG

Considering its properties, PETG excels in applications such as:

- Functional prototypes that need durability

- Containers and packaging

- Parts exposed to moisture or chemicals

- Articulated parts due to its flexibility

Making the Right Choice

Factors to Consider

When choosing between PLA, ABS, and PETG, consider the following factors:

Project Requirements: Identify the mechanical properties needed. For aesthetic models, PLA may be ideal; for structural components, ABS might be your best bet; and for flexibility and durability, PETG could be the answer.

Printer Compatibility: Check your printer’s compatibility with these materials. Some printers may perform better with specific filaments.

- Post-Processing Needs: If you plan to sand or paint your prints, ABS might be suitable due to its smooth finishing ability.

Conclusion

In the world of 3D printing, the choice of filament can significantly impact the quality and functionality of your printed objects. PLA shines for its ease of use and environmental benefits, ABS for its strength and thermal resistance, and PETG for its versatility and balance of properties. By understanding the differences among PLA, ABS, and PETG, you can select the filament that best meets your project’s specific needs and achieve superb results in your 3D printing endeavors. Happy printing!

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.