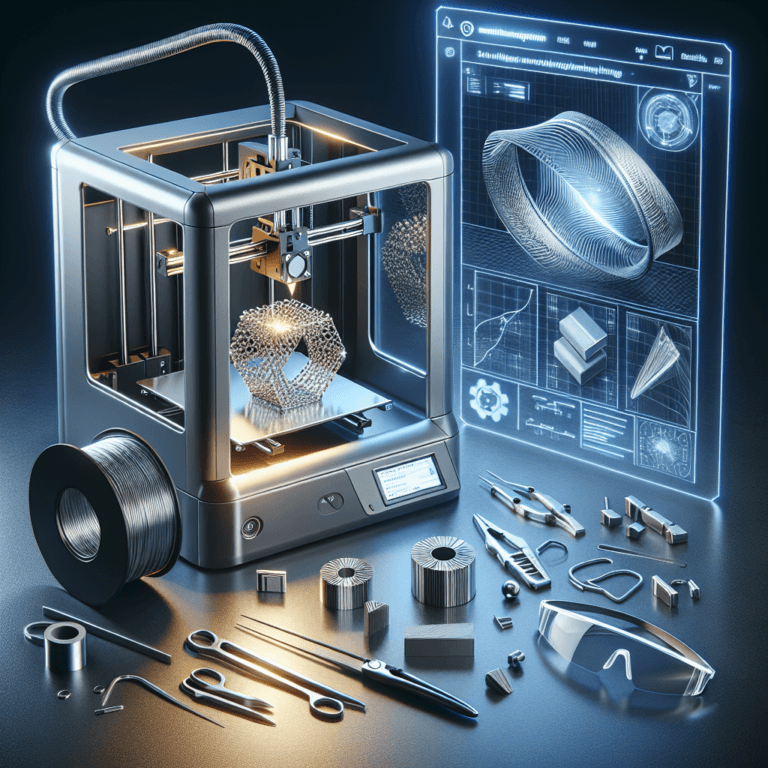

Introduction to 3D Printing Stainless Steel

3D printing has revolutionized manufacturing processes across various industries, and among its many applications, stainless steel printing stands out as a transformative technology. With the ability to produce intricate designs, reduce waste, and expedite production times, 3D printing in stainless steel has become a go-to solution for aerospace, automotive, medical, and many other sectors. This comprehensive guide will delve into various aspects of 3D printing stainless steel, exploring its advantages, processes, applications, and future trends.

Why Choose Stainless Steel for 3D Printing?

Stainless steel is renowned for its strength, durability, and resistance to corrosion, making it an appealing choice for 3D printing. Here are some reasons stainless steel is preferred:

Mechanical Properties: Stainless steel offers high tensile strength and can withstand extreme temperatures, making it suitable for demanding applications.

Corrosion Resistance: This material is inherently resistant to rust and oxidation, ensuring longevity in various environments, especially in industries like automotive and medical.

Versatility: Stainless steel can be easily alloyed with other metals to achieve specific properties, providing flexibility for various applications.

- Finish Options: Parts printed in stainless steel can be polished or treated to improve their aesthetic appeal and performance characteristics.

Types of 3D Printing Technologies for Stainless Steel

There are several methods to 3D print stainless steel components, each with its advantages and limitations. The most common technologies include:

Selective Laser Melting (SLM): This process involves using a powerful laser to fuse metal powder layer by layer, creating highly complex structures. SLM is known for producing strong and dense parts, ideal for industrial applications.

Direct Metal Laser Sintering (DMLS): Similar to SLM, DMLS also uses a laser to melt metal powders. However, DMLS focuses on producing parts that may require less surface finish treatment compared to those made by SLM.

Binder Jetting: In this technique, a binding agent is selectively deposited onto layers of metal powder. After printing, the part undergoes a sintering process to achieve its final form. Binder jetting is generally faster and can produce less expensive parts but may not achieve the same mechanical properties as methods involving laser melting.

- Metal Fused Deposition Modeling (FDM): This is a newer method for 3D printing with metals. In metal FDM, a metal filament is extruded layer by layer. While it may not reach the same density as laser-based methods, it offers faster production times and lower costs.

The 3D Printing Process of Stainless Steel

The production of stainless steel items via 3D printing typically involves the following steps:

Designing the Model: Engineers create a 3D digital model using Computer-Aided Design (CAD) software, ensuring that it adheres to the desired specifications and tolerances.

Slicing the Model: The CAD model is sliced into thin horizontal layers using slicing software, which also allows the user to adjust parameters such as layer thickness and print settings.

Printing: The sliced model is sent to the 3D printer, where the machine builds the object layer by layer. Depending on the technique used, the printer either binds or melts stainless steel powder to create the part.

Post-Processing: After printing, parts may undergo various post-processing steps like removing support structures, heat treatment, or surface finishing to achieve the desired properties and appearance.

- Quality Control: Final inspections ensure that the printed part meets the required quality standards and specifications.

Applications of 3D Printed Stainless Steel

The versatility of stainless steel 3D printing has led to its adoption in numerous industries:

Aerospace: 3D printing allows for the creation of complex components such as fuel nozzles, brackets, and other lightweight parts that can withstand extreme conditions.

Medical Devices: Custom surgical instruments, implants, and prosthetics are increasingly produced with stainless steel, leveraging 3D printing’s ability to tailor designs to individual patient needs.

Automotive: The automotive industry utilizes stainless steel 3D printing for rapid prototyping and production of parts that require high performance, such as exhaust systems and other components.

- Tooling and Manufacturing: Stainless steel 3D printing helps create custom tooling, jigs, and fixtures that enhance manufacturing efficiency.

Advantages of 3D Printing Stainless Steel

The shift to 3D printing with stainless steel comes with several compelling benefits:

Reduced Material Waste: Traditional manufacturing methods often result in significant waste; however, 3D printing produces parts layer by layer, minimizing waste to a fraction of conventional processes.

Speed: 3D printing can significantly reduce lead times for prototypes and parts, enabling quicker iteration and production times.

Complex Geometries: The ability to produce intricate geometries that are often impossible or cost-prohibitive to create with traditional manufacturing techniques is one of the major benefits of 3D printing.

- Cost-Effectiveness: While the initial investment in 3D printing technology can be high, the long-term savings associated with reduced waste, faster production times, and automation capabilities can result in lower overall costs.

Challenges in 3D Printing Stainless Steel

Despite its many advantages, 3D printing stainless steel does come with some challenges:

Material Limitations: Not all stainless steel alloys are suitable for 3D printing, and specific properties may limit the range of applications.

Post-Processing Requirements: Many printed stainless steel parts require considerable post-processing, including heat treatment and surface finishing, which adds to the overall production time and complexity.

- High Initial Costs: The technology and equipment for high-quality metal printing, while decreasing, can still require significant upfront investment.

Future Trends in 3D Printing Stainless Steel

As technology continues to evolve, several trends are emerging in the world of 3D printing stainless steel:

Improved Materials: Ongoing research aims to develop new stainless steel alloys that optimize properties for 3D printing, enhancing performance and expanding application possibilities.

Higher Production Speeds: Innovations in printing technologies are leading to faster production times, making 3D printing more competitive with traditional manufacturing.

Integration With Automation: The convergence of 3D printing with AI and automation technologies holds the potential to streamline the production process, further reducing costs and lead times.

- Sustainability: As environmental concerns rise, 3D printing is being explored as a more sustainable manufacturing option due to its ability to use less material and reduce waste.

Conclusion

3D printing in stainless steel represents a groundbreaking frontier in manufacturing, offering unparalleled design flexibility, efficiency, and material properties. As technology advances and applications continue to expand, businesses across various sectors are well-positioned to leverage the benefits of this innovative production method. Whether you’re an engineer, a manufacturer, or a researcher, understanding the nuances of 3D printing stainless steel will prove vital as you navigate the evolving landscape of modern manufacturing. Embrace the future today and explore the unlimited potential of stainless steel 3D printing for your projects.

This guide serves as a comprehensive resource to understand the ins and outs of this transformative technology, equipping you with knowledge that can drive innovation and efficiency in your endeavors.

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.