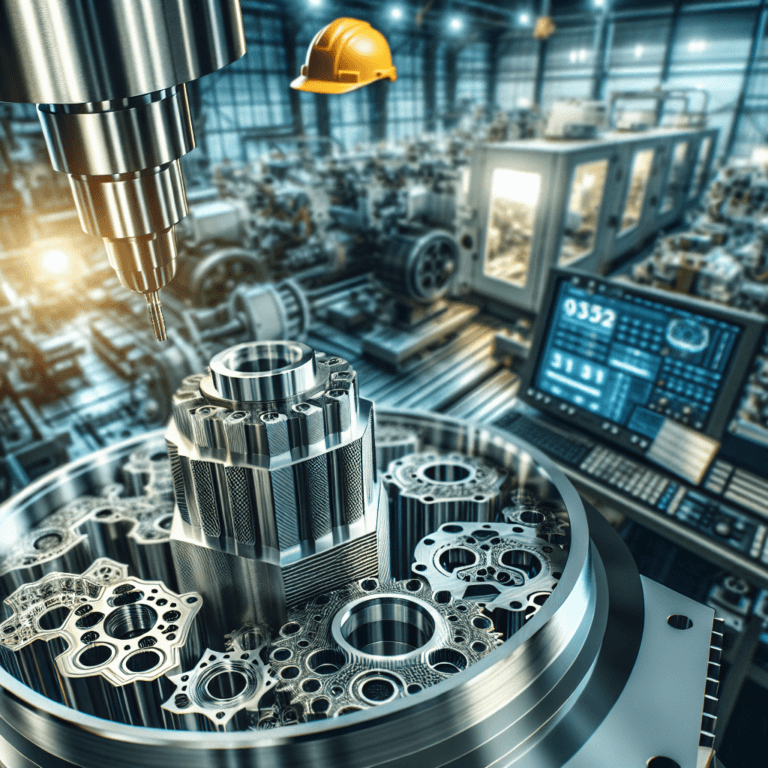

In the world of modern manufacturing, precision CNC (computer numerical control) metal machining stands out as a pioneering technology that has revolutionized the way we conceive, design and produce complex metal parts. This guide is designed to clarify the basic concepts, applications, techniques, and benefits associated with precision CNC metal machining, making it a valuable resource for beginners entering this dynamic field.

H2: What is precision CNC metal processing?

Precision CNC metal machining refers to the use of computer tools and machinery to create metal parts with specific precision and accuracy. The technology covers a range of operations that convert raw metal materials into fine products, often using methods such as milling, turning, drilling and electrical discharge machining (EDM). At the heart of the technology is the ability to transform complex designs in CAD (computer-aided design) software into real-world components, ensuring a high degree of consistency and quality.

H3: History of CNC machining

The journey of CNC machining began in the 1940s, driven by the need to improve the accuracy of manufacturing processes. Early versions utilized punched tape to control machine tools, which evolved over the decades into advanced digital systems. By the 1970s, CNC technology had matured and manufacturers began implementing these systems in various industries, achieving significant improvements in speed, accuracy, and repeatability.

H3: Working principle of CNC machine tools

CNC machine tools operate according to computer-generated code, known as G-code, which consists of a series of commands that instruct the machine’s movement and operation. The machine’s controller interprets this code and manages the movement of cutting tools or other machining components. Operators prepare and convert CAD designs into this machine-readable format, allowing for detailed control of the machining process.

H3: Key components of CNC machine tools

- Controller: this "brain" CNC machine tools convert G code instructions into actions.

- Drive system: These include motors and actuators capable of precise movement along designated axes (usually X, Y, and Z).

- Cutting tools: Tools such as end mills, drills, and lathes are used to remove material and shape the workpiece.

- Workbench: Fixes the surface of the workpiece, enabling precise positioning during machining.

- Feedback system: Sensors and encoders provide the controller with real-time data about the operating status of the machine.

H2: Accuracy of CNC machining

Precision CNC machining is characterized by the ability to produce parts with the smallest tolerances, typically measured in microns. This accuracy is critical in industries such as aerospace, automotive, medical devices and electronics, where even the slightest deviation can lead to catastrophic failure or poor performance.

H3: Tolerance and accuracy

- tolerant: This refers to the allowable limit of physical dimensional changes, which affects how tightly parts are assembled.

- accuracy: This provides a measure of how closely the machined part conforms to the design specifications.

Precision CNC machines can achieve tolerances as tight as ±0.005 inches (±0.127 mm) or tighter, depending on machine capabilities and operating parameters.

H2: Type of CNC machining process

CNC machining encompasses a variety of methods tailored to specific applications. Each technology has unique advantages depending on the required accuracy, material properties and throughput.

H3: CNC milling

CNC milling uses a rotating tool to remove material from a workpiece, usually a block of metal, to obtain the desired shape. This process allows for complex geometries and complex designs.

Applications of CNC milling:

- prototype

- Aerospace complex parts

- Components with various features such as holes and slots

H3: CNC turning

CNC turning is used to create cylindrical parts by rotating the workpiece while stationary cutting tools shape the workpiece. This technique is commonly used to make shafts, bolts and bushings.

Applications of CNC turning:

- auto parts

- Pipes and pipes

- fastener

H3: CNC drilling

CNC drilling is performed by using a drill bit to create holes in the workpiece. This process is often integral to other machining operations and allows for precise hole placement.

Applications of CNC drilling:

- Medical device parts

- Structural parts

- Components requiring precise hole locations

H3: Electrical Discharge Machining (EDM)

EDM is a non-traditional machining process that uses electric discharge to remove material from a workpiece. It is particularly effective on hard metals and complex shapes.

Applications of EDM:

- Mold

- Aerospace parts

- High precision parts

H2: Materials used in precision CNC machining

Material selection is critical for precision CNC machining as it affects machinability, surface finish, durability and functionality. Commonly used materials include:

H3: Metal

- aluminum: Known for its lightweight and corrosion resistance, aluminum is widely used in the aerospace and automotive industries.

- steel: Different grades of steel, such as stainless steel and tool steel, offer high strength and versatility in applications.

- titanium: Titanium is valued for its high strength-to-weight ratio and resistance to extreme temperatures, and is commonly used in biomedical applications and aerospace.

H3: Non-metallic materials

In addition to metals, CNC machining can also process non-metallic materials such as plastics, composites and ceramics. These materials are suitable for special applications, especially in areas such as electronics and medical devices.

H2: Advantages of CNC metal processing

Precision CNC metal machining offers numerous advantages over traditional manufacturing methods, driving its widespread adoption across various industries.

H3: Accuracy and consistency improve

CNC machining greatly reduces human error and increases overall accuracy. By repeatedly processing multiple units, consistency in quality is maintained, which is crucial for high-volume production.

H3: Enhance flexibility

Manufacturers can easily reprogram CNC machines to produce different parts or adjust designs, providing unparalleled flexibility in responding to changing market demands or custom orders.

H3: Cost efficiency

Although CNC machines may require a significant upfront investment, their automated features can reduce labor costs and increase production speeds, resulting in lower unit costs over time.

H3: Facilitate complex design

With the capabilities of CNC machining, even the most complex designs can be realized with relative ease. This innovation promotes creativity in engineering and design.

H2: Challenges and considerations of CNC machining

While CNC machining offers many advantages, it also comes with challenges. For those venturing into the world of CNC machining, understanding these challenges is critical.

H3: Initial cost

The investment in CNC machines and supporting software can be significant. Beginners should evaluate their budget and consider the long-term benefits to determine if CNC machining is the right path.

H3: Skill requirements

Although CNC machines automate many processes, operators must be proficient in programming, troubleshooting, and maintenance. To keep pace with technological advancements, ongoing training is necessary.

H3: Material restrictions

Not all materials are suitable for CNC machining, and some may require special tools or setup. Understanding material properties is crucial to optimizing the machining process.

H2: Application of precision CNC metal processing

CNC machining is used in numerous fields due to its versatility and precision. Here are some key areas where precision CNC metal machining excels:

H3: Aerospace industry

The aerospace industry requires extremely precise and lightweight components. CNC machining plays a vital role in manufacturing parts such as turbine blades, brackets and fuselage components.

H3: Automobile industry

From engine blocks to gear components, precision CNC machining is an integral part of the automotive industry, ensuring parts meet strict safety and performance standards.

H3: Medical equipment

Precision is critical in the medical field. CNC machining is used to manufacture surgical instruments, implants and prosthetics, where precision and reliability are critical.

H3: Electronic manufacturing

As components in gadgets become increasingly complex and miniaturized, CNC machining has become a mainstay in producing cases, stands and other components for consumer electronics.

H3: Defense sector

Weapons and defense systems require components that can withstand harsh conditions. Precision CNC machining enables reliable and durable parts critical to national security.

H2: Future trend of CNC machining

As technology develops, so does the field of CNC machining. Emerging trends are shaping the future of manufacturing:

H3: Integration of artificial intelligence and machine learning

Incorporating artificial intelligence can optimize CNC machining processes through predictive maintenance, increasing efficiency and reducing downtime.

H3: 3D printing integration

The fusion of CNC machining and 3D printing technologies enables rapid prototyping and production of complex geometries, broadening design possibilities.

H3: Sustainable manufacturing practices

As sustainability takes center stage, it is increasingly important to develop environmentally friendly practices in CNC machining, such as reducing waste and utilizing recyclable materials.

H3: The degree of automation increases

The trend toward greater automation of CNC machining will increase productivity, allowing manufacturers to produce large quantities of parts at lower labor costs.

in conclusion

Precision CNC metal machining is a key component of modern manufacturing, providing unparalleled accuracy, speed and flexibility when producing complex metal parts. As the industry continues to demand greater precision and efficiency, CNC machining will remain at the core of innovation and growth.

For beginners who want to explore CNC machining, this guide provides a basic understanding of its principles, processes, and applications. As technology and methods continue to advance, the future of CNC machining appears strong and full of opportunities.

FAQ

Q1: What are the main advantages of CNC machining over traditional machining?

A1: The main advantage of CNC machining is the ability to achieve high levels of accuracy and repeatability, thereby minimizing human error and increasing overall productivity.

Q2: How long does it take to learn CNC programming?

Answer 2: The time it takes to learn CNC programming varies, but beginners can usually master the basics in a few weeks to a few months, depending on prior knowledge and an investment of practice.

Q3: Can CNC machine tools process materials other than metal?

A3: Yes, CNC machines can process a variety of materials, including plastics, composites, and wood, making them versatile in different manufacturing areas.

Q4: What common tolerances can be achieved with CNC machining?

A4: Common tolerances in CNC machining range from ±0.005 inches (±0.127 mm) to ±0.0001 inches (±0.00254 mm), depending on the specific machine and tooling used.

Q5: Is CNC processing suitable for small batch production?

A5: Absolutely! CNC machining is not only suitable for mass production but also for small batch production because it allows for quick design changes without extensive downtime.

As the industry evolves, mastering CNC machining technology will enable engineers, designers and manufacturers to turn their innovations into reality and shape the future of manufacturing.

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.