In the ever-evolving world of manufacturing, the need for precision, efficiency and versatility has never been greater. Among the various materials and processes available to engineers and manufacturers, aluminum CNC (computer numerical control) machining stands out as the first choice for producing precision parts. This blog post takes an in-depth look at aluminum CNC machining, examining its benefits, applications, and the technologies that make this modern manufacturing process so effective. With a focus on scientific rigor and original insights, we aim to illuminate the many benefits of this innovative technology.

Learn about CNC machining

What is CNC machining?

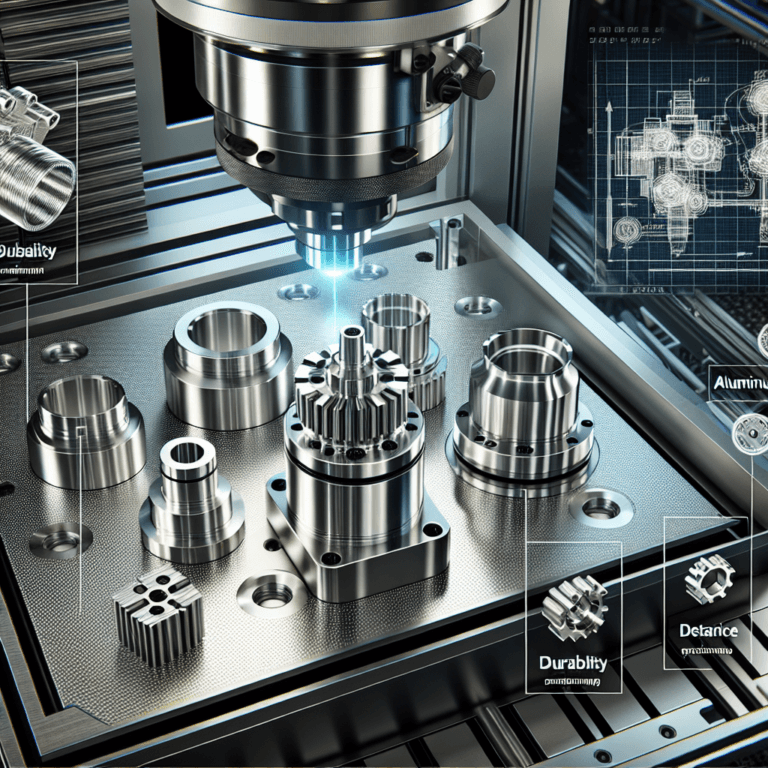

CNC machining is a method in which computers control the movement of manufacturing tools to shape raw materials into precision parts. CNC machining provides unparalleled precision, consistency and speed when producing parts to complex specifications. By programming computers to control tools such as mills, lathes and milling machines, manufacturers can produce complex geometries that are nearly impossible to achieve through manual machining methods.

The role of aluminum in CNC machining

Known for its lightweight, strength and corrosion-resistant properties, aluminum has become a favored material in many industries, including aerospace, automotive and medical. It is particularly suitable for CNC machining due to its unique properties, which we will explore in depth in this article.

Advantages of aluminum CNC machining

1. High precision and high tolerance

One of the most important advantages of aluminum CNC machining is the ability to produce high-precision parts. CNC machining technology allows tolerances as tight as ±0.002 inches (±0.05 mm). This level of accuracy is critical in industries such as aerospace and medical device manufacturing, where even the slightest deviation can lead to catastrophic results. Therefore, the precision provided by CNC machining enables designers and engineers to manufacture complex parts to exacting specifications.

2. Production efficiency

Aluminum CNC machining is also recognized for its efficiency. Because machines are able to operate continuously, especially in continuous production runs, manufacturers can produce large quantities of precision parts in a short period of time. This is especially beneficial in an era when speed to market is critical.

Additionally, CNC machining minimizes material waste through its precise cutting technology, often resulting in a more sustainable manufacturing process. The capabilities of modern CNC machine tools allow for rapid prototyping, where manufacturers can quickly produce prototypes for testing and validation before moving into full production.

3. Design Versatility

Aluminum CNC machining offers unparalleled versatility in part design. Unlike traditional machining techniques that may require redesigning tools for different parts, CNC machining can be adapted to produce various shapes and sizes by simply changing the program. Whether it’s a complex aerospace shell or a simple bracket, CNC technology can adapt to a variety of geometries, materials and finishes with relative ease.

4. Material characteristics and advantages

Aluminum is inherently a material suitable for CNC machining due to its unique properties:

light: Aluminum has an excellent strength-to-weight ratio, making it ideal for applications where weight reduction is critical, such as the aerospace and automotive sectors.

Corrosion resistant: Aluminum offers excellent corrosion resistance, extending the life of components, especially in harsh environments. This is particularly advantageous in marine applications or outdoor equipment.

thermal conductivity: Aluminum has high thermal conductivity, making it ideal for components that require efficient heat dissipation, such as heat exchangers or electronic enclosures.

- Machinability: Aluminum is easier to machine than harder metals like steel, resulting in longer tool life and faster productivity.

5. Cost-effectiveness

While the initial investment in CNC machinery can be significant, the long-term savings often outweigh these upfront costs. CNC machine tools can operate continuously, enabling mass production while reducing labor costs. In addition, the material efficiency of CNC machining can minimize waste and reduce material expenses.

In addition to production costs, aluminum itself is relatively cheap compared to other metals such as titanium or high-grade steel. As a result, manufacturers can take advantage of aluminum’s properties while maintaining cost efficiency.

Application of Aluminum CNC Machining

Aluminum CNC machining is not only popular for its advantages; It is also widely applicable to various industries. Here are some important areas where this technology excels:

1.Aerospace

In the aerospace industry, precision and weight are critical. Aluminum’s lightweight properties and exceptional strength make it a perfect choice for components such as brackets, housings and body structures. The ability to achieve high tolerances is critical because these parts must withstand considerable stress during flight.

2. Car

The automotive industry is increasingly turning to aluminum to make lightweight vehicle parts, improving fuel efficiency and reducing emissions. Parts such as engine blocks, transmission housings and wheels can be produced using CNC machining, ensuring durability and performance.

3. Medical devices

In the medical field, precision is non-negotiable. CNC machining enables manufacturers to produce complex surgical instruments, implants and housings that comply with strict health regulations. Aluminum’s non-corrosive properties and biocompatibility further enhance its demand in this field.

4. Electronic products

CNC machining is critical in the electronics industry, with aluminum commonly used in heat sinks, housings, and various electronic components. The material’s ability to effectively manage heat is critical to maintaining the performance of electronic devices.

5.Industrial equipment

Many industrial applications benefit from aluminum CNC machining, including the manufacture of machinery, conveyors and frame components. The combination of strength, lightness and precision makes aluminum the best choice for this type of application.

Aluminum CNC processing process

Understanding the CNC machining process helps illustrate its advantages in producing precision aluminum parts. Here is an overview of the typical steps involved:

1. Design and Prototyping

The first step in CNC machining involves creating a detailed 3D model of the part using CAD (computer-aided design) software. The model serves as a blueprint for the CNC machine tool. Engineers can use rapid prototyping technology to create physical models to verify designs before mass production.

2. Programming

Once the design is complete, it must be converted into a format that the CNC machine can understand. This involves creating G-code (the programming language for CNC machine tools), which determines every movement of the cutting tool. Advanced CAD/CAM (computer-aided manufacturing) software can significantly simplify this process.

3. Material preparation

Prepare aluminum ingots or blocks for machining. This preparation may include cutting the aluminum to rough size and making sure it meets thickness and size specifications.

4. Mechanical processing

During the machining phase, the CNC machine removes material from the aluminum block according to programmed instructions. This may involve a variety of techniques, including milling, turning and drilling. The process is typically monitored to ensure tolerances are maintained throughout the operation.

5. Organize

After the machining process is complete, additional finishing processes such as grinding, polishing, or anodizing may be required. These steps enhance the surface finish of the part and can improve corrosion resistance, appearance, or conductivity.

6. Quality Control

Quality control is an important part of the aluminum CNC machining process. After machining, parts are typically inspected using a coordinate measuring machine (CMM) to verify dimensions and tolerances. This rigorous quality assurance ensures that every part produced meets required specifications.

Challenges faced by aluminum CNC machining

While aluminum CNC machining offers numerous advantages, several challenges must be addressed to maximize efficiency and product quality:

1. Tool wear

Although aluminum is easier to machine than many metals, it can cause rapid tool wear if not managed properly. The high speeds of CNC machining, combined with the thermal and mechanical stresses during cutting, can affect tool life. Implementing a proper cooling mechanism and selecting the correct cutting tool are critical to minimizing wear.

2. Material variability

Not all aluminum alloys behave the same during machining. Changes in composition, tempering and processing can affect machinability. Machinists must be familiar with the specific grade of aluminum they are working with to optimize the machining parameters for each project.

3. Tolerance management

Given the precision required for CNC machining, achieving tight tolerances can sometimes be a challenge, especially for extremely thin walls or complex designs. Careful programming, tool selection and machine calibration are critical to maintaining tight tolerances throughout the production process.

4. Initial setup time

While CNC machining is highly efficient in the production process, the initial setup time can be lengthy. This includes programming, tool calibration and fixture attachment. Manufacturers must weigh the time investment against the efficiency of the overall production run to determine feasibility.

in conclusion

Aluminum CNC machining is at the forefront of modern manufacturing methods, with a unique combination of precision, efficiency and adaptability. The material’s inherent advantages, coupled with the advanced technology of CNC machine tools, make it an ideal solution for the production of complex parts across a variety of industries.

From aerospace to automotive applications, the benefits of CNC machining of aluminum are undeniable. Whether it is enhancing product design, optimizing production processes or reducing costs, this innovative practice will continue to shape the future of manufacturing.

As technology advances, we can foresee greater possibilities for CNC machining, with improved materials, smarter software, and more efficient processes driving the industry forward. Manufacturers hoping to take advantage of these advantages must stay informed of current developments and maintain a forward-thinking approach to integrating new technologies as they emerge.

FAQ

1. What is the difference between CNC processing and traditional processing?

CNC machining uses computer-controlled machinery to produce parts with high precision and consistency, while traditional machining relies on manual intervention, resulting in a higher potential for human error and variation.

2. Why is aluminum commonly chosen for CNC machining?

Aluminum is often chosen for CNC machining due to its excellent machinability, lightweight properties, corrosion resistance and cost-effectiveness, making it suitable for a variety of applications and industries.

3. How high can CNC machining accuracy be?

CNC machining can achieve tolerances as tight as ±0.002 inches (±0.05 mm), making it extremely precise and suitable for applications that require high precision, such as aerospace and medical equipment.

4. What are the most common applications of aluminum CNC machining?

Common applications include aerospace components, automotive components, medical equipment, electronic enclosures and industrial machinery components.

5. How does surface finish affect the performance of machined parts?

Surface finishing can enhance the surface quality of machined parts, improve corrosion resistance, increase wear resistance, and affect the overall aesthetics, making it a crucial step in the CNC machining process.

6. What are the best maintenance practices for CNC machine tools?

Maintaining CNC machine tools includes regular cleaning, routine inspections, lubricating moving parts, calibrating tools and replacing worn parts to ensure optimal performance and longevity.

By understanding the benefits and applications of aluminum CNC machining, manufacturers and engineers can make informed decisions that enhance their production capabilities, resulting in better product outcomes and greater operational efficiency.

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.