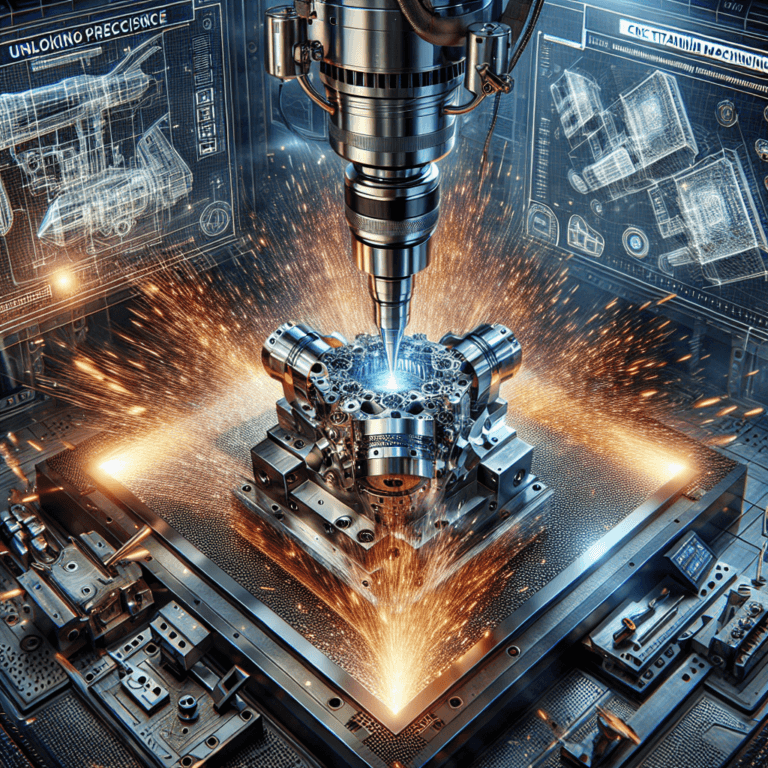

The manufacturing process of titanium components stems from its unique physical and chemical properties. Emerging capabilities in CNC (computer numerical control) machining are revolutionizing the field of titanium machining, increasing the accuracy, scalability and complexity of designs. In this comprehensive guide, we take an in-depth look at the advanced technologies for CNC titanium machining, how they optimize production and the challenges facing this specialized field.

Learn about titanium and its properties

Before diving into the details of CNC titanium machining technology, it is necessary to understand the basic properties of titanium. Titanium is a transition metal with a high strength-to-weight ratio, excellent corrosion resistance, and biocompatibility. These features make it ideal for various industries including aerospace, medical devices, automotive and defense.

Titanium properties

- light: The density of titanium is about 4.5 g/cm3, which is about 45% lighter than steel.

- strong: Titanium has high tensile strength, with grades such as Ti-6Al-4V (the most commonly used titanium alloy) exceeding 900 MPa.

- Corrosion resistant: Titanium forms a stable oxide layer that protects it from environmental corrosion, making it suitable for harsh conditions.

- biocompatibility: Titanium is non-toxic and inert in the human body, making it the material of choice for medical implants.

Now that we understand the inherent properties of titanium, we can now explore CNC titanium machining techniques to effectively utilize these properties.

CNC machining technology

CNC machining is a subtractive manufacturing process that uses computer-controlled machines to cut, shape and finish materials. The process requires several stages, including designing the part, programming the CNC machine, and executing the operation.

Stages of CNC machining

design parts: Engineers use CAD (computer-aided design) software to create 2D or 3D models of titanium parts. This digital representation allows simulation and adjustment before machining.

CNC machine tool programming: CAD files are converted into compatible G-code—a language that CNC machines understand that details motion, speed, and tool paths.

- machining process: CNC machine tools execute programmed instructions to shape titanium workpieces using rotating tools such as end mills and drills.

Types of CNC machining technology

Milling: This technique involves using a rotating cutting tool to remove material from a workpiece. It is particularly beneficial for creating complex parts with complex geometries.

turning: This is performed on a lathe where the titanium workpiece is rotated relative to the cutting tool. Turning is mainly used for cylindrical parts with high precision.

EDM (Electrical Discharge Machining): This unconventional machining technique uses sparks to remove metal, making it easy to machine hard materials and delicate designs without applying mechanical force.

- laser cutting: High-power lasers can cut titanium with extreme precision. This technique works well for intricate designs and is known for its clean cuts and minimal incisions.

Advanced Technology for CNC Titanium Machining

Optimizing CNC titanium machining requires understanding its challenges and deploying expertise. These advanced methods maximize efficiency while maintaining the accuracy and integrity of titanium components.

1. Tool selection and optimization

Choosing the right cutting tool is crucial for CNC titanium machining. Due to their hardness and heat resistance, tools made of carbide or high-speed steel with coatings such as TiN, TiAlN or diamond are preferred.

Tool optimization technology:

geometry: Selecting cutting tools with appropriate geometry (e.g., fluted or fluted designs) can help control chip flow and avoid tool sticking.

- coating: Use proper cutting tool coatings to minimize friction and extend tool life. For titanium, coatings that enhance thermal conductivity are particularly beneficial.

2. Cutting parameters

Incorrect cutting parameters can lead to rapid tool wear, reduced surface finish quality and thermal deformation.

Key parameters to monitor:

cutting speed: For titanium alloys, the initial speed should be moderate, usually between 20 and 80 m/min. Finding the optimal speed reduces heat and extends tool life.

Feed rate: It is crucial to strike a balance between feed speed and processing time. Start with a lower feed rate (for example, 0.1 to 0.6 mm/rev) and adjust based on tool wear and performance.

- cutting depth: Shallow depth reduces cutting forces and allows for better control. Gradually increase depth based on tool and machine stability.

3. Coolant and Lubrication Technology

Proper cooling is critical to mitigating the heat generated when cutting titanium alloys, which can cause tool wear or even failure.

suggestion:

flood cooling: Uses a high-pressure flood cooling system to keep tools and parts cool while ensuring effective chip evacuation.

- Minimum quantity lubrication (MQL): This involves using a minimal amount of biodegradable lubricant to reduce heat and adhesion without flooding the work area.

4. Vibration control

CNC machining of titanium can be plagued by vibration, which affects the quality and integrity of the part.

How to control vibration:

Knife holder: Using vibration-damped toolholders helps reduce chatter and improves surface finish.

- Machine adjustment: Adjusting the machine’s settings to minimize vibration (such as a fixed table) can significantly improve results.

5. Post-processing technology

After machining, titanium parts often require a finishing process to achieve the required surface quality and tolerances.

Common post-processing techniques:

grinding: Use grinding tools for fine adjustments to achieve a superior finish, especially for precision parts.

- Surface treatment: Techniques such as anodizing or sandblasting can enhance the corrosion resistance and aesthetics of titanium parts.

Challenges Facing CNC Titanium Machining

While CNC titanium machining opens up new avenues for product innovation, it also presents unique challenges. Understanding and mitigating these issues is key to continued productivity.

1. High tool wear rate

The hardness of titanium causes the tool to wear out quickly. These high wear rates increase production costs and time.

2. Fever

Titanium has poor thermal conductivity, causing excessive heat to be generated during processing. This heat can damage the integrity of the tool and affect the accuracy of the part.

3. Difficulty in chip removal

Titanium chips are difficult to remove due to their ductility and tendency to form filamentous chips, which can interfere with machining operations and affect surface finish.

in conclusion

CNC titanium machining is an important process in modern manufacturing, especially in areas such as aerospace and medical applications that require high-performance materials. By employing advanced technologies such as optimal tool selection and cutting parameters, effective cooling methods and post-machining treatments, manufacturers can realize the full potential of titanium’s performance.

As the manufacturing field continues to evolve with technology and innovation, CNC titanium machining holds great promise. Continuous technology research and adaptation ensures that industries can meet the growing demands for precision and performance in a rapidly changing world.

FAQ

Q1: What are the advantages of using titanium for manufacturing?

A1: Titanium has a high strength-to-weight ratio, excellent corrosion resistance and biocompatibility, making it ideal for a variety of applications including aerospace, medical and automotive.

Q2: Why is CNC processing preferred for titanium parts?

A2: CNC machining offers high precision, scalability, and the ability to create complex geometries that meet the tight tolerances required in today’s manufacturing environment.

Q3: What are the effects of improper cutting parameters used in CNC titanium machining?

A3: Incorrect cutting parameters can cause rapid tool wear, poor surface finish, excessive heat generation, and can compromise the integrity of the titanium part.

Question 4: How do manufacturers address the challenges of titanium CNC machining?

A4: Manufacturers can mitigate challenges by carefully selecting cutting tools, optimizing cutting parameters, implementing effective cooling methods, and using vibration reduction technology.

Q5: Which post-processing technologies are suitable for titanium parts?

A5: Suitable post-processing techniques include grinding for precision machining and surface treatments (such as anodizing) to enhance corrosion resistance and surface aesthetics.

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.