In the world of automotive tuning, the cylinder head is often overlooked, but it is a crucial component that can significantly impact engine performance. A well-designed and manufactured cylinder head can improve engine efficiency, boost power output, and enhance overall vehicle performance. In this article, we will explore the importance of CNC machining of customized cylinder heads for automotive tuning and the benefits it can offer.

The Need for Customized Cylinder Heads

Mass-produced cylinder heads are designed to meet the requirements of the average engine, but for performance enthusiasts and tuners, this standard head may not be enough. A customized cylinder head can be tailored to meet specific performance goals, such as increased power output, improved fuel efficiency, or enhanced engine durability.

Advantages of CNC Machining

CNC machining offers several advantages for the manufacturing of customized cylinder heads. This process allows for precise control over the machining process, ensuring high accuracy and precision in the production of complex geometries and surface finishes.

Increased accuracy: CNC machining allows for the creation of complex shapes and surface finishes that would be difficult or impossible to achieve by hand. This is particularly important for cylinder heads, where precise porting, combustion chamber design, and valve control are critical for optimal performance.

Improved surface finish: CNC machining can produce surface finishes that are smoother and more consistent than what can be achieved by hand. This is important for reducing friction, improving heat transfer, and increasing overall engine efficiency.

- Increased speed and efficiency: CNC machining can be done rapidly and efficiently, allowing for the production of complex parts in a shorter amount of time.

Design Considerations

When designing a customized cylinder head, several factors must be considered to ensure optimal performance. These include:

Combustion chamber shape and size: The shape and size of the combustion chamber can have a significant impact on engine performance. A properly designed combustion chamber can improve engine efficiency, power output, and overall performance.

Porting and timing: The design of the intake and exhaust ports, as well as the timing of the valve opening and closing, can significantly impact engine performance. Properly designing these components is crucial for optimal engine performance.

Valve design and placement: The design of the valves, including the shape, size, and placement, can also impact engine performance. Properly designed valves can improve airflow, reduce friction, and increase overall engine efficiency.

- Material selection: The selection of the right material for the cylinder head can also play a critical role in its performance. The material must be strong, durable, and resistant to heat and corrosion.

CNC Machining Process

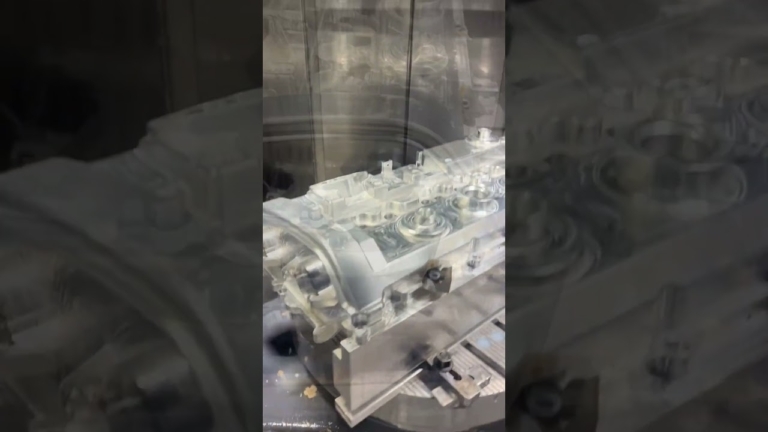

The CNC machining process for a customized cylinder head typically begins with the design phase, where the desired specifications and performance goals are defined. The design is then used to create a computer-aided design (CAD) model, which is used to generate the necessary toolpaths and programming for the CNC machine.

The CNC machine is then used to mill the cylinder head, carefully following the designed path to create the desired shape and surface finish. The entire process is highly precise, and even the slightest deviation can result in suboptimal performance.

Benefits of CNC Machining for Automotive Tuning

The use of CNC machining for the production of customized cylinder heads offers several benefits for automotive tuners and performance enthusiasts. These include:

Improved performance: A customized cylinder head can be designed to meet specific performance goals, such as increased power output, improved fuel efficiency, or enhanced engine durability.

Increased accuracy and precision: CNC machining allows for the creation of complex shapes and surface finishes that would be difficult or impossible to achieve by hand, resulting in improved engine performance and reduced maintenance.

Cost savings: By reducing the need for labor-intensive hand-finishing operations, CNC machining can help reduce production costs and lead times.

- Consistency and reliability: The precision of CNC machining ensures consistent results, reducing the risk of human error and increasing the reliability of the finished product.

Conclusion

In conclusion, CNC machining of customized cylinder heads is an essential process for automotive tuners and performance enthusiasts seeking to improve engine performance, power output, and overall vehicle performance. By understanding the importance of design considerations, the benefits of CNC machining, and the process itself, tuners can create high-performance cylinder heads that meet their specific goals and needs. Whether for racing, street, or daily driving, a well-designed and manufactured cylinder head can make all the difference in achieving optimal engine performance.

The use of CNC machining for the production of customized cylinder heads has revolutionized the automotive tuning industry, offering unparalleled accuracy, precision, and consistency in the manufacture of these critical components. As the demand for high-performance vehicles continues to grow, the need for high-quality, customized cylinder heads will only continue to increase, making CNC machining an essential component of the automotive industry’s future.

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.