Automobile manufacturing has always been a complex process that requires precision, accuracy, and high-quality components. With the increasing demand for customized parts, the need for advanced manufacturing techniques has become more important than ever. This is where GL CNC Machining comes in, offering cutting-edge solutions for precision parts production.

Recently, our team at [Company Name] has manufactured a new part that showcases our expertise in GL CNC Machining. As one of the leading providers of precision parts in the industry, we are dedicated to meeting the needs of our customers and exceeding their expectations. In this article, we will take a closer look at this new part, highlighting its features, benefits, and the manufacturing process involved.

The New Part: A Precise Solution for the Automobile Industry

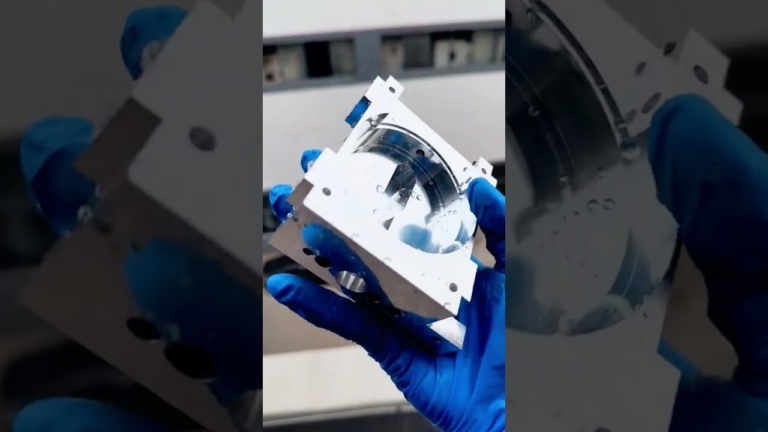

The new part we recently manufactured is a precision-crafted component designed specifically for the automobile industry. With its unique features and advanced design, it offers a range of benefits for automakers and manufacturers. The part is made from high-quality materials, carefully selected to ensure maximum strength, durability, and resistance to wear and tear.

Design and Material Selection

The design and material selection of the new part were critical steps in its manufacturing process. Our team of experienced engineers worked closely with our clients to understand their specific requirements and preferences. By combining cutting-edge CAD technology with expert knowledge, we created a design that meets the highest standards of precision and performance.

The part is made from a high-quality stainless steel alloy, chosen for its exceptional strength, corrosion resistance, and durability. This material selection ensures that the part can withstand the demands of high-performance applications, while also providing a long lifespan and reduced maintenance needs.

CNC Machining: The Backbone of Precision Manufacturing

At [Company Name], we are committed to providing high-precision parts through our expertise in CNC machining. This advanced manufacturing process allows us to produce complex components with unparalleled accuracy and precision. By using computer-aided design (CAD) software and computer numerical control (CNC) machines, we can create intricate designs and shapes with exacting tolerances.

In the case of the new part, our CNC machines were used to precision-cut, drill, and machine the component with incredible accuracy. This ensures that each part meets the highest standards of quality and performance, with every detail carefully considered and executed to perfection.

Manufacturing Process: From Design to Production

The manufacturing process for the new part was a collaborative effort that involved several stages. From design development to production, our team worked tirelessly to ensure that every detail was carefully considered and executed.

Stage 1: Design Development

The initial stage involved the design development of the part, where our team created a comprehensive CAD model detailing the component’s features, shape, and function. This stage was critical in ensuring that the part met the specific requirements of our clients and the industry’s standards.

Stage 2: Tooling and Economic Production

With the design complete, our team moved on to the tooling and economic production stage. This involved the creation of cutting tools, fixtures, and jigs, as well as setting up the production equipment. Our experienced technicians and operators worked together to fine-tune the machines, ensuring that every component was produced to the highest standards of quality.

Stage 3: Inspection and Testing

The final stage of the manufacturing process involved a rigorous inspection and testing regime. Every part was inspected visually and mechanically, with tests conducted to verify its performance, strength, and durability. Our team worked closely together to ensure that every part met the highest standards of quality, functionality, and safety.

The Benefits of GL CNC Machining

The new part we recently manufactured is just one example of the many benefits that can be achieved through GL CNC Machining. This advanced manufacturing technique offers numerous advantages, including:

- Increased Precision: GL CNC Machining allows for unparalleled precision, enabling the production of complex components with exacting tolerances.

- Reduced Lead Times: By using computer-aided design and computer-controlled machines, we can reduce production times and lead times, ensuring faster delivery to our clients.

- Improved Quality: The combination of CAD software and CNC machines enables us to produce flawless, high-quality parts, reducing the need for rework or re-manufacturing.

- Cost Savings: GL CNC Machining minimizes waste, reduces material consumption, and optimizes production, resulting in significant cost savings for our clients.

Conclusion

The new part we recently manufactured is a testament to our expertise in GL CNC Machining. By combining advanced technology, expertise, and meticulous attention to detail, we can create precision parts that meet the highest standards of quality, performance, and functionality. Whether you are an automaker or a manufacturer, our team at [Company Name] is dedicated to providing customized solutions that help you stay ahead in the fast-paced world of manufacturing. Contact us to learn more about our GL CNC Machining services and how we can help you achieve your goals.

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.