Precision CNC machining is at the forefront of modern manufacturing, capable of producing parts with extremely tight tolerances. This level of accuracy is not only optional; It’s a necessity in countless industries, from aerospace and medical devices to automotive and electronics. But what exactly makes precision CNC machining so special, and why is it crucial to your project? Let’s dig into the details.

Understand tight tolerances and their importance

In manufacturing terms, tolerance refers to the allowed variation in dimensions. Therefore, tight tolerances mean that the variations allowed are very small—often measured in thousandths of an inch or even microns. Achieving such precision requires specialized equipment, skilled machinists and strict quality control processes.

Why is this so important? Components with tight tolerances ensure:

- Improved performance: When parts fit together perfectly, the system operates more efficiently and reliably. Think of a perfectly aligned gear system or a precisely fitting medical implant.

- Enhanced durability: Minimizing gaps and stress points through precise assembly reduces wear and extends product life.

- Improve security: In critical applications such as aerospace and automotive, tight tolerances are critical for safety. An ill-fitting part can have disastrous consequences.

- Reduce assembly time and costs: Parts manufactured to precise specifications require minimal rework or adjustments during assembly, saving time and money.

- Better aesthetics: For visible parts, tight tolerances ensure a clean, professional finish that enhances the overall appeal of the product.

The role of five-axis CNC machining

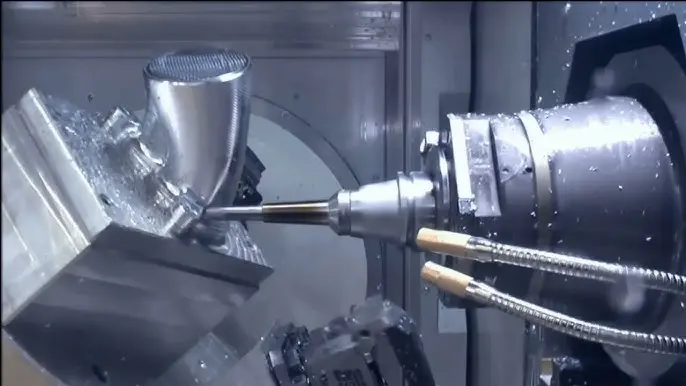

While traditional CNC machining (such as 3-axis) can achieve decent accuracy, 5-axis CNC machining takes accuracy to a whole new level. In addition to three linear axes (X, Y, and Z), five-axis machines have two rotary axes. This allows the cutting tool to approach the workpiece from virtually any angle, allowing complex geometries and complex features to be created in a single setup.

The advantages of five-axis CNC machining for tight tolerance machining are many:

- Reduce setup time: By machining multiple sides of a part in one setup, five-axis machining minimizes the need for repositioning and refixing, which can introduce errors.

- Improve accuracy: Fewer settings means less opportunity for cumulative error. The ability to machine complex features without moving parts ensures consistent dimensional control.

- Better surface finish: The ability to obtain different angles allows for smoother cuts and improved surface finishes, which is critical for parts that require optimal performance and aesthetics.

- Greater efficiency: Five-axis machining can often complete parts faster than traditional methods, reducing lead times and overall costs.

- Complex geometry capabilities: This enables the production of highly complex parts that would be difficult or impossible to manufacture using traditional methods.

Gretel: Your precision CNC machining partner

At GreatLight, we specialize in providing high-quality, tight-tolerance CNC machining services using advanced five-axis CNC equipment. We understand the critical importance of precision in various industries and are committed to providing parts that meet the most demanding specifications.

Here’s what sets GreatLight apart:

- Advanced equipment: We invest in state-of-the-art five-axis CNC machines to ensure exceptional precision and reliability.

- Experienced mechanics: Our team of skilled machinists have the expertise and attention to detail needed to consistently achieve tight tolerances.

- Comprehensive material capabilities: We can work with a variety of materials including aluminum, steel, stainless steel, titanium, plastic and more.

- Strict quality control: We employ strict quality control procedures throughout the manufacturing process, using precision measuring equipment to verify that parts meet specified tolerances.

- One-stop service: In addition to machining, we also offer a range of post-processing and finishing services, including anodizing, powder coating, heat treatment.

- Quick turnaround time: We are committed to providing our customers with fast turnaround times without compromising on quality.

Hongliang CNC machining technology

Our CNC machining process is designed to ensure accuracy and efficiency at every stage:

- Design and Engineering Review: Our experienced engineers review your design to identify potential manufacturing challenges and provide recommendations for optimizing precision machined parts.

- CAM programming: We use advanced CAM (Computer Aided Manufacturing) software to generate precise tool paths that guide CNC machines.

- Material selection: We help you choose the best material for your application based on factors such as strength, weight, corrosion resistance and cost.

- Processing: Our skilled machinists use five-axis CNC machines to precisely cut parts based on programmed tool paths.

- Quality control: We use precision measuring equipment, such as coordinate measuring machines (CMM), to verify that parts meet specified tolerances.

- Post-processing and finishing (optional): We offer a range of post-processing and finishing services to enhance the appearance and functionality of your parts.

in conclusion

Precision CNC machining, especially with five-axis capabilities, is critical for industries that require tight tolerances and complex geometries. GreatLight is well-equipped and skilled to meet these needs, and we are committed to providing high-quality, precise parts that meet your exact specifications. Contact us today to discuss your project and experience the GreatLight difference!

Frequently Asked Questions (FAQ)

- What tolerances can GreatLight achieve with CNC machining?

We can consistently achieve tolerances of +/- 0.001 inch (0.025 mm) or tighter, depending on part geometry, materials and other factors. We will work with you to understand your specific tolerance requirements and ensure they are met.

- What materials can Honglaite process?

We have extensive experience processing a variety of materials, including aluminum alloys (6061, 7075, etc.), steel alloys (carbon steel, stainless steel, tool steel, etc.), titanium, brass, copper, plastics (ABS, polycarbonate, nylon, etc.) and more. If you have a specific material, please contact us to discuss its suitability for CNC machining.

- What file formats are accepted for CNC machining?

We accept a variety of file formats, including STEP, IGES, DXF, DWG and STL. 3D models are preferred, but we can also use 2D drawings.

- What is the typical lead time for a CNC machining project?

Delivery times vary based on part complexity, quantity required and material availability. After reviewing your project requirements, we will provide you with a detailed delivery time estimate. We also offer expedited service for urgent projects.

- How do I get a quote for CNC machining services?

Simply contact us by phone or email and provide your design files (2D drawings or 3D models) and project requirements. We will review your information and provide you with a competitive quote within a short period of time.

- Does GreatLight provide design assistance?

Yes, our experienced engineers can provide design assistance to optimize your part’s manufacturability and reduce costs. We can review your design and provide suggestions for improvements.

- What quality control measures does Gretel use?

We adopt strict quality control measures throughout the entire processing process, including first article inspection, in-process inspection and final inspection. We use precision measuring equipment, such as coordinate measuring machines, to verify that parts meet specified tolerances. We also maintain comprehensive documentation to ensure traceability.

- What is five-axis CNC machining?

Five-axis CNC machining refers to a CNC machining process in which the tool moves on five axes at the same time. These axes are X, Y and Z (linear axes) and A and B (rotary axes). This allows the tool to approach the workpiece from almost any direction in one setup.