Unlocking innovation and efficiency: Why small batch CNC machining innovates prototypes and production

Fast and cost-effective high-quality parts are crucial in today’s fast-paced innovation-driven market. That’s where small batch CNC processing is done. Unlike mass production, small batch CNC focuses on providing lower quantities of precisely manufactured components – considering prototypes, functional testing units, professional tools or limited production runs. This approach provides unparalleled flexibility, reduced lead times, reduced initial costs, and the ability to iterate quickly without the need for large inventory commitments. For engineers, designers and businesses push boundaries, it has become an indispensable resource.

Input five-axis CNC machining: technology to take small batch production to a new level. Traditional three-axis machines are limited; they can only approach the workpiece from three directions. Five-axis machining introduces two additional axes of rotation (usually A and B). This allows the cutting tool to approach the workpiece from almost any angle in a single setup. The impact on small batch manufacturing is revolutionary:

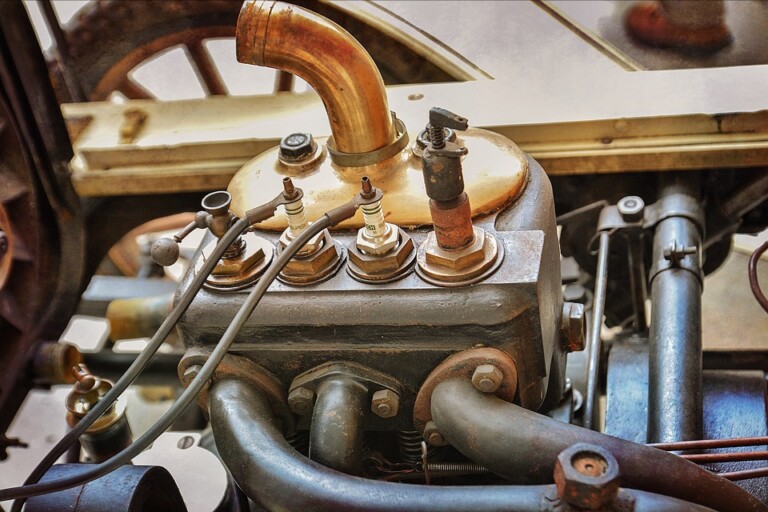

- Complex geometric shapes make it simple: Complex contours, deep cavity, undercut and organic shapes require multiple setups and fixtures on a 3-axis machine to be simple. Think about impellers, aerospace components, medical implants or complex automotive parts. The five-axis machine simply tilts and rotates the workpiece to reach the necessary angle.

- Unparalleled precision: Reducing settings minimizes cumulative errors. When machining parts in a fixture, alignment errors between operations are almost eliminated, resulting in excellent dimensional accuracy and tighter tolerances – critical for demanding applications.

- Top surface finish: The ability to maintain optimal tool orientation relative to the surface continuously performs smoother finishes, reducing the need for manual polishing or secondary finishes.

- Delivery time: Complex parts that have previously taken days and set up can now be completed in a few hours on a five-axis machine. Faster iterations mean faster time to market.

- Material Savings: Accurate tool paths and conversion of reduced waste from setup errors to more efficient material usage reduce costs per part despite advanced technology.

- Less fixtures and tool changes: Flexibility minimizes the need for complex custom fixtures and constant tool changes, simplifying the entire process.

Choosing the Right Partner: Why Greatlight performs well in small batches of five-axis CNCs

The complexity of navigation customization, precise machining requires partners with advanced features, expertise and commitment to excellent service. This is Great Distinguish between yourself:

- The most advanced five-axis Arsenal: Gregtime is not only equipped with equipment; it is strategically equipped with an advanced five-axis CNC machining center. This technology is their core capability, enabling them to cope with the most challenging geometric shapes and precise requirements inherent in high-value small batches and prototypes.

- Master Metals: They have deep expertise in handling a variety of engineering metals – from regular aluminum and stainless steel to harder alloys such as titanium, inconel, inconel, brass, copper and special tool steels. Understanding each material properties, cutting parameters and tool selection are critical to quality results.

- Streamline production technology: In addition to the original processing capabilities, Greatlight Leverages’ exquisite production processes improve efficiency. This includes optimized CAM programming, strategic tool path planning, in-process monitoring and strict quality control protocols for the entire production integration.

- Comprehensive solution provider: Greatlight understands that parts usually require more than just machining. They provide A true one-stop feature Provides extensive internal post-processing and sorting services. This includes:

- Surface treatment: Precise grinding, polishing, grinding, bead blasting.

- Paints and platters: Anodizing (various types), painting, powder coating, electroplating (nickel, chromium, zinc, etc.), passivation.

- Heat treatment: The hardening, tempering, annealing required for material properties.

- Laser marking/engraving: Traceability and brand cultivation are essential.

- Non-standard packaging: Ensure that the parts arrive perfectly.

- Unrivaled flexibility and customization: Do specific alloy modifications need? Need an abnormal surface texture? Limits to push tolerances? Gremphiem thrives in customization. Their expertise enables them to adapt quickly and effectively to unique customer specifications.

- Speed meets value: "Customize your precision parts now at the best prices!" Not just a slogan – it’s a promise. Good lighting utilizes their technical advantages and efficient workflows to provide fast turnaround time without sacrificing quality, allowing small batches to truly access advanced five-axis accuracy. The economics of avoiding expensive molds or short-term set-up time make them extremely compelling.

Is the small batch of five-axis CNC suitable for your project?

Absolutely, if you need:

- Rapid prototyping: Functional prototypes that accurately represent the final physical form and material properties.

- Bridge production: Blink the gap between prototype and full-scale manufacturing in small quantities.

- Low-volume production: Manufacture specialized end-use parts without large minimum order quantity (MOQ).

- Replacement parts: Create components for mass production of old equipment or custom machinery or for mass-producing old machines.

- Highly complex components: Geometrically complex parts require multi-axis machining.

Conclusion: The precise advantages of agile manufacturing

Small batches of CNC machining, supercharged by five-axis technology, is no longer a niche market. This is a strategic advantage. It empowers innovation, accelerates development cycles, mitigates financial risks to new products, and provides unparalleled accuracy on demand. Working with experts is key when you need this level of competence and quality. Greatlime, with in-depth investment in advanced five-axis machining, extensive material expertise, comprehensive post-processing and commitment to fast, cost-effective solutions, is a major option. For businesses that require precision, complexity, speed and value in their custom metal parts, Greatlight offers the manufacturing advantages needed to succeed.

Ready to turn your design into high-precision reality? Explore how Greatlight’s small batch five-axis CNC solution gives your next project.

Frequently Asked Questions about Small Batch Five-Axis CNC Machining (FAQ)

Q1: What is the minimum order quantity (MOQ) for small batch CNCs on Greatlight?

A: Gremplying specializes in real small batch production. Although the prototype of fertilization can be less than 1 piece, a typical small production run may be in the range of 5 to 500 parts. Their focus is flexibility, so they often accommodate projects that do not have strict and large quantities of requirements.

Q2: What materials can be used in small batches of Greatlight Machines?

A: Greglight is used with a large number of metals suitable for CNC processing, including but not limited to: aluminum (various alloys), stainless steel (300 and 400 series), carbon steel, copper, brass, copper, titanium, titanium, Inconel, tool steel. They can provide advice on the best materials for your specific features and budget needs.

Q3: How long does it usually take to obtain parts from small batch orders?

A: Delivery time depends on the project, but it is much faster than the quality production method. Prototypes can usually be shipped within a few days. For typical small batches, production usually takes 1-2 weeks, depending on the complexity of the parts, completion requirements and current workload. Greatlight takes the priority of fast turnaround as a core benefit.

Question 4: How does the five-axis function benefit compared to my parts?

A: Five-axis machining is excellent when parts have complex geometry, undercuts, features on multiple faces, or require extremely high accuracy and smooth finishes. It eliminates the need for multiple settings, saves time, costs and reduces potential errors. If your design is relatively simple (flat or prismatic), a 3-axis may be enough, but a 5-axis provides excellent functionality for complex components. Greglight can advise on the best approach.

Q5: Can Greatlight handle the entire process, including completion and gold plating?

A: Yes, this is a key advantage. Greatlight provides comprehensive internal post-processing and sorting services. This ensures seamless coordination throughout the workflow, consistent quality control (processing, burring, cleaning, surface treatment, if needed (if needed), and overall delivery time for finished parts is faster.

Q6: How does Greatlight ensure the quality of small batch production?

Answer: Quality is crucial. Greatlight uses precise measurement tools (e.g. CMM, surface tester, height measurements) to rigorous process inspections. Their expertise in advanced five-axis machining inherently improves higher accuracy. From material verification to final inspection before shipping, a comprehensive quality control procedure is integrated at each stage.

Question 7: Is the small batch CNC processing cost-effective for my project?

A: For low to medium and complex parts, usually More Cost-effective alternatives, such as injection molding (needing expensive tools) or machines using multiple settings. Eliminate tool costs, reduce material waste from an optimized five-axis path, and short lead times make it economically attractive in prototypes, bridge production, specialized parts and limited operations. Greatlight focuses on maximizing value with custom precision at the best price.