Revolutionizing Precision: The Unmatched Capabilities of CNC Follow-Up Grinders

In the relentless pursuit of manufacturing perfection, the CNC follow-up grinder emerges as a quantum leap beyond conventional grinding technology. By fusing computer numerical control with advanced servo systems and real-time feedback, these machines transcend static operations, dynamically adapting each grinding pass to achieve unprecedented levels of precision. This synergy transforms traditional grinding from a fixed-path operation to an intelligent, responsive process that redefines manufacturing possibilities.

Evolutionary Engineering: Beyond Traditional Grinding

Unlike manual or hydraulic grinders locked into predetermined paths, CNC follow-up grinders analyze workpiece geometry through integrated sensors, adjusting grinding wheel position, angle, and pressure during each operation. This "follow-up" capability allows the machine to maintain optimal contact with complex contours, whether tackling internal grooves, tapered surfaces, or irregular profiles. Forged steel components demanding ±0.1μm tolerances or intricate medical implants requiring flawless surface finishes are now within consistent reach—an impossible feat with legacy equipment.

The Precision Paradigm: Core Technical Advantages

Adaptive Micron-Level Control

Real-time servomotor adjustments govern grinding wheel trajectory down to micrometer precision. Advanced CNC algorithms continuously compensate for thermal drift, wheel wear, and material inconsistencies. Example: When grinding hardened turbine blades, the system automatically increases wheel rigidity during high-stress passes while reducing force during finishing cycles, maintaining ±2μm profile tolerance across batches.Closed-Loop Quality Assurance

Integrated laser scanners and touch probes create a feedback loop between measurement and action. During operation, the system detects subsurface anomalies or dimensional deviations, triggering instantaneous grinding parameter corrections. This eliminates post-process inspection rework—critical for aerospace components where a single flawed bearing race could cascade into system failure.Multi-Axis Flexibility

Equipped with 5-7 programmable axes, modern units perform compound-angle grinding without repositioning. A single setup handles threading, grooving, and contouring operations. In mold manufacturing, this enables simultaneous grinding of core/cavity surfaces with perfect alignment, cutting production time by 60% compared to conventional methods.- Self-Optimizing Efficiency

AI-driven software analyzes historical performance data to predict optimal grinding strategies. Parameters like wheel speed, coolant flow, and infeed rates dynamically adjust to material hardness variations. Tests show 30% power savings versus traditional grinders while reducing cycle times through intelligent path optimization.

Industry-Specific Transformations

Aerospace Turbine Manufacturing

CNC follow-up grinders achieve mirror finishes (Ra ≤ 0.05μm) on nickel-alloy engine blades while preserving compressive surface stresses that prevent fatigue cracks. Real-time adjustments compensate for the blade’s aerodynamic twist, grinding each section at the ideal abrasive angle—impossible with fixed automation.

Medical Implant Production

When machining titanium spinal implants, the system’s micro-adjustments maintain uniform surface porosity for optimal osseointegration. Biocompatibility requires burr-free edges; the grinder’s pressure sensors detect material transitions, reducing wheel pressure near delicate features to prevent microfractures.

Automotive Transmission Systems

For gear grinding, the machine autonomously shifts between generating gear and profile grinding modes based on tooth geometry. During production of helical gears, it dynamically varies helix angle alignment as the workpiece rotates, ensuring flank profile consistency within 3 microns across thousands of units.

Silicon Wafer Handling Components

In semiconductor equipment, robotic end-effectors require flatness ≤1μm over 300mm spans. The grinder’s thermal compensation negates heat-induced distortion during dry grinding of ceramics, while piezoelectric actuators make 10,000 adjustments per second to maintain parallel grinding plane alignment.

Smart Manufacturing Integration

Leading CNC follow-up grinders now incorporate IoT connectivity for Industry 4.0 ecosystems. Data streams from vibration sensors, power monitors, and surface analyzers feed into predictive maintenance systems and digital twins. At a Bavarian auto parts plant, this integration reduced unplanned downtime by 73% by forecasting wheel wear and scheduling replacements during planned pauses. Cloud-based analytics further optimize grinding protocols across global factories, elevating quality consistency manufacturing-wide.

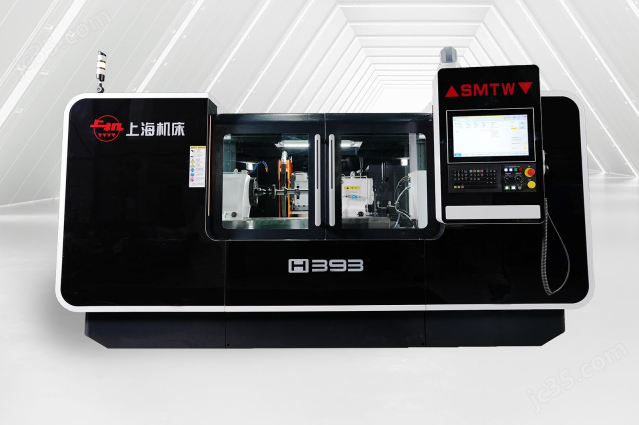

Precision in Motion: Real-time adjustments maintain wheel contact during contour grinding of aerospace alloys

The New Precision Economics

Beyond technical prowess, these grinders deliver transformative ROI:

- Setup Time Reduction: Template-free programming slashes changeovers from hours to minutes

- Consumable Savings: Adaptive force control extends diamond wheel life by up to 40%

- Scrap Elimination: Closed-loop systems achieve near-zero defect rates in high-volume runs

- Labor Efficiency: One technician oversees multiple machines producing complex geometries untouchable by manual methods

As manufacturing embraces increasingly intricate designs—from bio-mimetic medical devices to multi-fuel engine components—CNC follow-up grinding stands as the enabling technology. Its convergence of nano-precision, cognitive adaptability, and seamless data integration doesn’t just improve existing processes; it unlocks frontiers in metallurgy, miniaturization, and functional surface engineering previously deemed unmanufacturable. The age of passive grinding machinery has ended, replaced by systems that think, react, and perfect with every revolution of the wheel.