The Evolution of Precision Manufacturing: How CNC Machining Centers Change Industry

The manufacturing world has undergone significant shifts in recent years, driven by advances in technology and the growing demand for precision and customization. One of the main drivers of this transformation is the introduction of computer numerical control (CNC) machining centers that have revolutionized the way parts are made. In this article, we will dig into the world of CNC machining centers and explore its strengths, capabilities and future of precision manufacturing.

What is a CNC machining center?

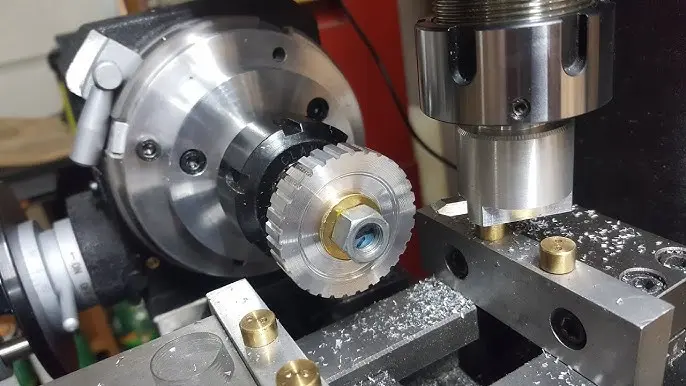

The CNC machining center is a computer-controlled machine that uses a variety of cutting tools to remove materials from workpieces, creating precise and intricate shapes and designs. These machines are designed to perform multiple tasks, including milling, drilling and grinding, making them an essential tool in modern manufacturing.

Advantages of CNC machining centers

Compared with traditional manufacturing methods, CNC machining centers offer several advantages, including:

- Improve accuracy: CNC machine can be in +/-. Production of parts with excellent accuracy and precision within 0001 inches.

- Faster production time: With the ability to automate many tasks, CNC machining centers can produce parts faster than traditional methods.

- flexibility: CNC machines can handle a variety of materials from metal to plastic and can be programmed to perform complex operations.

- Reduce labor costs: By automating many tasks, CNC machining centers reduce the demand for manual labor, thus reducing production costs.

Application of CNC machining center

CNC machining centers are used in a variety of industries, including:

- aerospace: Produce complex aircraft parts and components.

- car: Create precision engine and chassis components.

- Medical: Manufacture of medical implants, instruments and other equipment.

- Industrial:Produce parts for industrial machinery and equipment.

The Future of CNC Machining Center

As technology continues to evolve, we can expect to see significant improvements in CNC machining centers, including:

- Increase speed and productivity: New machine design and algorithms will enable production time and higher accuracy.

- Artificial Intelligence Integration: AI-driven CNC machining centers will optimize the production process, reduce errors and improve overall efficiency.

- Additive Manufacturing: The integration of 3D printing technology will enable the creation of complex geometric shapes and structures.

in conclusion

CNC machining centers have revolutionized the manufacturing industry, thus giving excellent accuracy and speed to complex parts. As technology continues to evolve, we can expect to see significant improvements in CNC machining centers, further changing the way parts are made. Whether you are a manufacturer looking for reliable partners or an engineer looking for innovative solutions, CNC machining centers are an essential tool for pursuing precise manufacturing.

Frequently Asked Questions

- What materials can a CNC machining center handle?

- A: Most metals, plastics and other materials can be processed using CNC machining centers.

- How accurate is CNC machining centers?

- Answer: Modern CNC machining centers can be found in +/-. Accuracy within 0001 inches.

- Can CNC machining centers handle complex geometry?

- A: Yes, CNC machining centers can handle complex geometric shapes, including 3D printing and additive manufacturing.

- What are the benefits of using a CNC machining center?

- A: CNC machining centers provide improved accuracy, faster production time, flexibility and reduced labor costs.

- Can CNC machining centers be used for small batch production?

- A: Yes, CNC machining centers can handle small batches of production and are ideal for prototyping and low-volume production.