Optimizing the Selection of Gear Friction Machine Equipment for Efficient Production

In the manufacturing of automotive transmission parts, the teeth friction process is a widely used technique for treating external splines with modules less than 2 mm, offering advantages of high efficiency, high precision, high load capacity, and material savings. This process is commonly used for the treatment of external splines of speed shafts in traditional manual transmissions, new energy reducers, and new energy engines. Due to the diverse spline modules, pressure angles, diameters of the upper circle of teeth, and effective widths in splines of different products, various types of gear scrub must be selected during process design. The selection of gear scrub transformation equipment must not only meet the requirements of product processing technology and ensure product quality but also take into account economy. Therefore, how to select the equipment has become the key to the processing design.

Unbalanced Production Capacity: A Problem to Be Solved

In the current market, the production capacity of the 1500-type speed friction machine is insufficient, while the production capacity of the 1000-type speed friction machine is overcapacity. This has resulted in the problem of unbalanced production capacity between the two models. To solve this problem, it is necessary to increase the utilization rate of the 1000-type speed friction machine to alleviate or resolve the production capacity pressure of the 1500-type gear machine, thus avoiding new equipment investments.

Analysis of 1000 and 1500 Rubber Process Parameters

The maximum dental friction module, the maximum external diameter of dental friction, the maximum dental friction, the maximum length of the part, the maximum installation width of the dental friction plate, and the opening size can be selected according to the settings of the shape and spline of the product to be treated. The number of friction rings determines the length of the friction plate, and the number of friction rings is linked to the pressure angle of the part to be treated. Therefore, it is only after the number of friction rings that the mounting plate specifications may be determined.

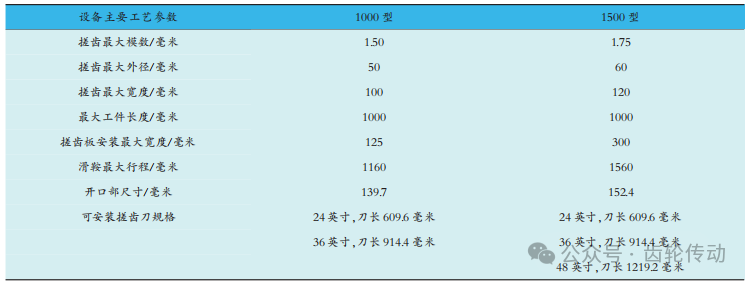

Main Process Parameters of 1000 and 1500 Speed Traction

As shown in Table 1, the main process parameters of 1000 and 1500 speed traction include the maximum dental friction module, the maximum external diameter of dental friction, the maximum dental friction, the maximum length of the part, the maximum installation width of the dental friction plate, and the opening size.

Selecting the Number of Friction Rings

Usually, the splines at a pressure angle of 30 degrees must be rubbed for more than 8 laps, the splines at a pressure angle of 37.5 degrees must be rubbed for more than 7 laps, and the splines at a pressure angle of 45 degrees must be rubbed for more than 6 laps. The more the number of teeth rubs, the more the amount of teeth lifts and the less the number of teeth rubs, the larger the amount of teeth.

Calculating the Number of Friction Rings

The lifting designing of teeth lifting of the dental roller plate is generally not more than 0.003 mm. The calculation of the dental elevator is mainly linked to the large diameter of the spline, the small Spline diameter, and the design of the dental number of the piece of the part to be treated. When selecting the equipment, the teeth lifting the dental roller plate can be calculated using formulas (1) – (3).

Recalculating the Dental Elevator of the 1500-type Speed Friction Machine

By using formulas (1) – (3), the dental elevator of the 1500-type speed friction machine can be recalculated. The results are presented in Table 2.

By calculating the production capacity of speed friction machines 1000 and 1500, the dental elevators of products 1, 2, and 3 are all less than 0.003 mm. Among them, product 1 has significant demand. If product 1 can be treated in the type 1000 speed friction machine, the problem of insufficient production capacity of the 1500-type gear machine can be resolved, and the use rate of the two equipment is close to balance.

Improvement and Verification

From Table 2, although the SPPLINE PRODUCT PRESSURE OF PRODUCT 2 and product 4 are also 30 degrees, the number of cerebral vascular accidents is only 7 laps, or 1 less than the above-mentioned race plate. Consequently, the number of friction speed rings should not be strictly selected according to the corresponding number of pressure angle of 30 degrees 8 rpm, pressure angle of 37.5 degrees 7 rpm, and pressure angle of 45 degrees 6 rpm.

The number of product rings 1 is reduced to 7 rpm and the teeth lift is obtained at 0.0028 mm, the length of the tool is 901.64 mm, that is to say that the teeth of the tool is less than 0.003 mm and the length of the tool is less than 36 inches. To guarantee the feasibility of product processing 1 on the side machine 1000, it has been confirmed with the tool manufacturer that the speed friction machine 1000 can meet the product processing requirements 1. The length of the dental friction plate is 36 inches and 914 mm.

The improved dental milk plaque has been checked for compliance and stability, and 50 pieces have been continuously treated. The precision of the Spline was qualified for the equipment detection center. The accuracy of the Spline could be stable at level 6 specified in "Sprape Cylindrical Strap Involute Splines (Metter Modular and Digital Dooth Side Matching) Part 1: General thesis (GB / T 3478.1-2008). The dental friction plate was used continuously for 3 months, and the quantity of treatment did not reach 20,000 pieces. Obvious damage, and the tool machine has not vibrated.

Conclusion

Thanks to the method of selecting the gear exhaust exhaust model, product treatment 1 and product 3 between type 1000 type exhaler and type 1500 type strewber is reached, which does not only solve the product processing problem 1 but also improve the production capacity of the 1500-type gear machine, thus achieving a more balanced production capacity and reducing the risk of new equipment investments. By selecting the appropriate gear friction machine, manufacturers can optimize production efficiency, reduce costs, and improve product quality.