Unlocking the Secrets of Stress Relief: A Comprehensive Guide to Reducing Residual Stress in Engineering Projects

Stress problems are an inherent part of engineering projects, ranging from design and manufacturing to construction and operation. In our previous articles, we have explored methods of stress simulation and detection. In this article, we will delve into the significance of stress relief and explore various methods to eliminate residual stress, which can detrimentally impact engineering products.

Understanding Residual Stress

Residual stress, also known as residual thermal stress, is a common phenomenon that occurs during various manufacturing processes, such as welding, casting, forging, or machining. This stress is generated due to the rapid cooling of materials, leading to internal micro-cracks, dimensional instability, reduced resistance, and increased risk of fatigue and corrosion.

Methods of Stress Relief

Fortunately, there are various methods to eliminate residual stress, each with its unique characteristics. These methods can be broadly classified into natural aging, thermal aging, vibration aging, sub-resonance aging, cold work stretching, and ultrasonic impact.

Natural Aging

Natural aging is a passive process that involves placing the material in a natural environment, allowing it to slowly relax over time. This method is not commonly used in production due to its slow and inefficient nature, typically requiring more than a year to achieve a limited stress relief reduction of 2-10%.

Thermal Aging

Thermal aging involves heating the material to a specific temperature range (500-650°C) and then slowly cooling it. This method can effectively eliminate most residual stress, but it may cause surface oxidation and degradation of the material’s performance.

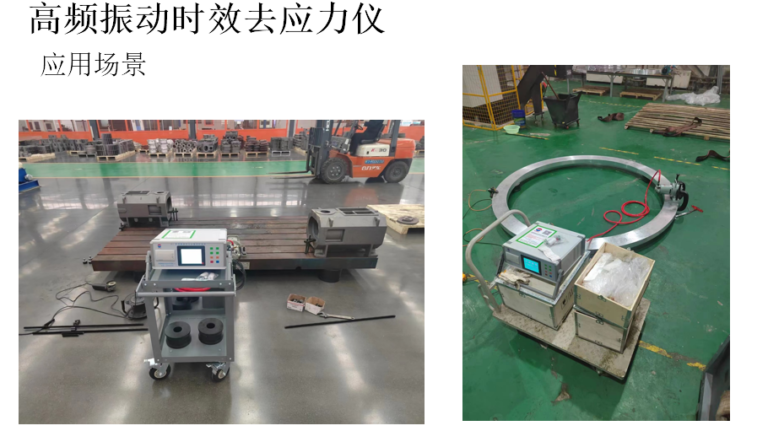

Vibration Aging

Vibration aging, also known as vibrational stress relief, is a popular method that applies periodic external forces to the material, resonating it to reduce or eliminate residual stress. This method is energy-efficient and suitable for various part sizes, exhibiting an impressive 30-90% reduction in residual stress.

Sub-Resonance Aging

Sub-resonance aging, a technique that utilizes stress relief through sub-resonance, is an eco-friendly option, but it requires complex operation and can only partially eliminate stress, making it less widely applied.

Cold Work Stretching

Cold work stretching involves stretching or rolling the material to adjust the grain structure and eliminate internal stress. This approach can improve material performance and dimensional stability, but it requires careful control to prevent excessive deformation and surface degradation.

Ultrasonic Impact

Ultrasonic impact is a highly effective method that generates high-frequency vibrations to plastic-compress the metal surface, modifying the stress field and introducing beneficial compression stresses. This technique is particularly suitable for post-welding treatment, eliminating residual weld stress and improving fatigue resistance.

Choosing the Right Stress Relief Method

When selecting a stress relief method, it is essential to consider the material’s characteristics, part size and shape, and production requirements. Different materials may require specific treatment approaches, such as temperament processing after heat treatment to eliminate residual stress. For example, large structural parts may be more suitable for thermal and vibration aging, while smaller components may opt for sub-resonance aging or ultrasonic impact.

Case Studies: Real-Life Stress Relief Applications

In conclusion, choosing the right stress relief method is crucial to enhance the quality, reliability, and lifespan of engineering products. By understanding the different methods, we can select the most appropriate approach for our specific needs, eliminating residual stress and ensuring the overall performance and safety of our designs.

Stay tuned for more insights and updates on stress management and relief.