Mastering the Art of CNC System Control Software: Streamlining Work Processes for Enhanced Productivity

In the ever-evolving world of manufacturing, CNC (Computer Numerical Control) systems have revolutionized the way we produce goods and products. With the ability to automate and streamline processes, CNC systems have become the backbone of many industries. However, effective management of these systems requires a deep understanding of the software and work processes involved. In this article, we will delve into the world of CNC system control software and explore the key elements that can help optimize work processes and improve productivity.

The Anatomy of CNC System Control Software

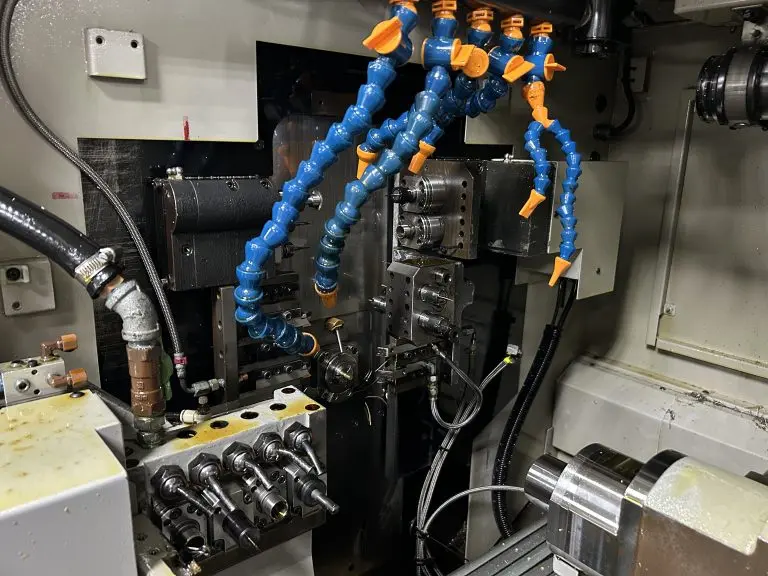

CNC system control software is the brain behind the operation of CNC machines. It is responsible for processing design data, generating toolpaths, and control machine motion to produce the desired outcome. The primary function of CNC system control software is to translate design data into a language that the machine can understand, allowing for precise control over the machining process.

Key Features of CNC System Control Software

- G-Code Generation: This feature enables the software to generate G-code, a programming language understood by CNC machines, to control the cutting tool’s movement and operation.

- Post-Processing: This function refines the G-code by optimizing cutting toolpaths, reducing machining time, and improving part quality.

- Simulation and Verification: This feature allows for simulation and verification of the machining process, enabling users to predict potential issues and optimize the process.

- Machine Monitoring and Control: This module provides real-time monitoring and control of the machine, enabling remote monitoring, data logging, and automatic tool replacement.

- Data Management: This feature enables the management of project data, including design files, part information, and machining parameters, for easy access and retrieval.

Streamlining Work Processes

To maximize the benefits of CNC system control software, it is essential to understand the importance of a well-planned and organized work process. Here are some key strategies to help streamline your work processes:

- Up-to-date Design and Production Information: Ensure that all design and production information is accurate, complete, and up-to-date to reduce errors and improve communication.

- Standardized Toolholders and Cutting Tools: Implement standardized toolholders and cutting tools to reduce inventory management and ensure effective communication with machine operators.

- Prioritized Machining Tasks: Prioritize machining tasks to optimize machine utilization and reduce lead times.

- Multi-Machine Scheduling: Schedule machining tasks across multiple machines to maximize productivity and reduce idle time.

- Quality Control and Assurance: Implement regular quality control checks to ensure compliance with industry standards and regulatory requirements.

Best Practices for CNC System Control Software Maintenance

To ensure the optimal performance of CNC system control software, regular maintenance is crucial. Here are some best practices to follow:

- Regular Backups: Regularly backup your design and production data to prevent data loss in case of system failure or corruption.

- Software Updates: Regularly update your CNC system control software to ensure you have the latest features and bug fixes.

- Machine Maintenance: Schedule regular maintenance for your CNC machines to prevent downtime and optimize performance.

- Operator Training: Provide ongoing training for machine operators to ensure they are familiar with the CNC system control software and can troubleshoot issues efficiently.

- Monitoring and Logging: Monitor system performance and log data to identify trends, optimize processes, and improve machine performance.

Conclusion

CNC system control software is the backbone of modern manufacturing, enabling precision control over machine operation and streamlining work processes. By understanding the key features of CNC system control software and implementing best practices for maintenance and operation, manufacturers can optimize productivity, reduce lead times, and improve part quality. Remember, a well-planned and organized work process is essential to unlocking the full potential of CNC system control software.