CNC machining of aerospace parts: a critical process

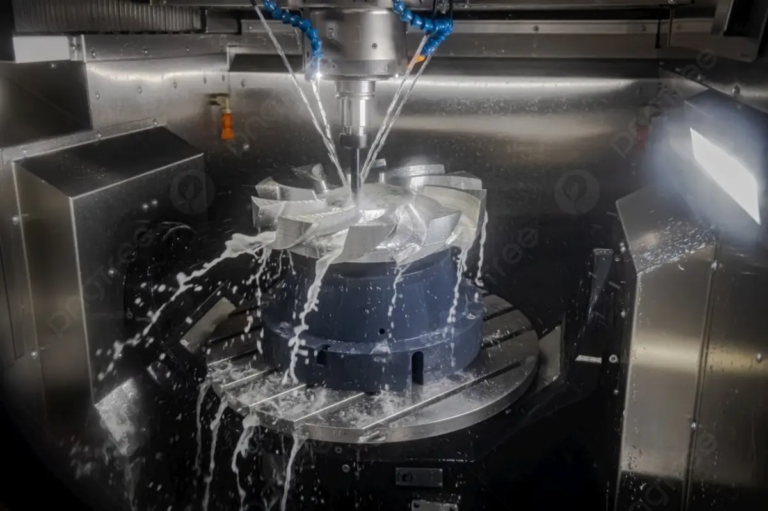

In the aerospace industry, the manufacturing of parts is a highly complex and critical process. One of the most important steps in this process is CNC machining, which involves cutting and shaping materials based on specific designs and specifications using a computer numerical control (CNC) machine. In the aerospace industry, CNC machining is a crucial step in the production of aircraft, spacecraft and other aircraft components.

The importance of CNC machining in aerospace manufacturing cannot be exaggerated. The industry requires reliable and durable high-precision parts, and CNC machining is able to produce parts with tight tolerances and precise dimensions. In fact, CNC machining is often used in conjunction with other manufacturing processes such as 3D printing and machining to produce complex parts with complex geometric shapes and characteristics.

There are many benefits to using CNC machining in aerospace manufacturing, including:

- Improve accuracy: CNC machining allows the production of parts with tolerance and accuracy dimensions, which is crucial in the aerospace industry.

- Improved accuracy: CNC machining reduces the risk of human error and ensures that the parts are made into the exact specifications.

- Faster production time: CNC machining can significantly reduce production time, allowing manufacturers to press on time and reduce costs.

- Reduce material waste: CNC processing minimizes waste generation, reduces waste and costs.

In addition, CNC machining can be used to produce a wide range of aerospace components, including:

- Aircraft structure:CNC machining can be used to produce complex aircraft structures such as wings, fuselages and control surfaces.

- Engines and Components:CNC machining can be used to produce engine components such as blades, blades and cases, as well as other components such as landing gears and fasteners.

- Spacecraft components: CNC machining can be used to produce components of spacecraft, such as satellite structures, rocket components and instruments.

As far as the CNC machining process itself is concerned, many different techniques and techniques can be used, including:

- Three-axis machining: This is a traditional CNC machining process that uses three linear axes (X, Y, and Z) to move the cutting tool back and forth along a predetermined path.

- Five-axis machining: This is a more advanced CNC machining process that uses five linear axes (X, Y, Z and two additional rotation axes) to move the cutting tool in multiple directions, allowing more complex part geometry and functionality to move the cutting tool.

- Two-axis machining: This is a specialized CNC machining process that uses two linear axes (X and Y) and one rotating axis (Z) to move the cutting tool, allowing for the production of complex parts with asymmetric geometry.

In short, CNC machining is a key process in the aerospace industry, enabling the production of high-precision parts with tolerance and accuracy dimensions. CNC machining has many benefits and functions and is an important tool for manufacturers of aircraft, spacecraft and other aerospace components.

Frequently Asked Questions

Q: What is CNC processing?

A: CNC machining is a manufacturing process that uses a computer numerical control (CNC) machine to cut and shape materials according to specific designs and specifications.

Q: What are the benefits of CNC processing in aerospace manufacturing?

A: The benefits of CNC machining in aerospace manufacturing include improved accuracy, improved accuracy, faster production times and reduced material waste.

Q: Some examples of aerospace parts that can be processed using CNC?

A: Aerospace parts that can be produced using CNC machining include aircraft structures, engines and components, and spacecraft components.

Q: What common CNC processing technologies are used in aerospace manufacturing?

Answer: Common CNC machining technologies used in aerospace manufacturing include three-axis machining, five-axis machining and two-axis machining.

Q: What is the importance of precision in the aerospace manufacturing industry?

A: In aerospace manufacturing, accuracy is crucial because even small errors or deviations in part of the geometry and size can have serious consequences in the performance and safety of the aircraft.