1. Definition of welding

Welding is a local binding process of metals or non-metals by heating the material to the welding temperature, by pressurizing or not under pressure, or by pressurizing, using or without filling of materials, the link is “connected together “, So welding refers to the operation activity of the implementation of connections.

2. Common welding methods

Manual arc welding (SMAW), arc welding protected by gas (GMAW), flow arc welding (FCAW), arc welding by gas (GTAW), arc welding submerged (saw)

3. Other welding methods

Plasma welding (PAW), electroslag welding (ESW), oxyacetylene welding (OAW), stall welding (SW), Laser beam welding (LBW), Electron beam welding (EBW), resistance welding (RW), brazing

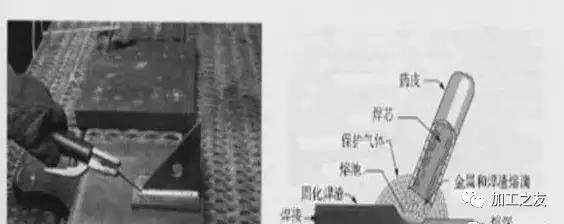

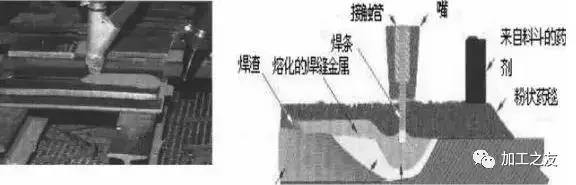

Manual arc welding (SMAW)

The welding metal is heated by the arc between the powdered welding rod and the metal welded to heat, thus achieving the objective of the welding. As shown in the figure, the arc of the welding rod and the part is caused by the current, which provides thermal energy and bottoms the basic material, filling metal and medicine. Form a layer on the surface. The most important element of manual arc welding is the welding rod itself, which is made of a layer of granular flow and a kind of adhesive covering the metal nucleus. All carbon and steel steel electrodes with low alloy are essentially in a low carbon steel wire as a nucleus, and the alloy elements come from the skin, which is also a relatively economical alloy method.

Characteristics of manual arc welding:

1. The equipment is simple and inexpensive, which makes welding with a manual arc very light;

Because a variety of welding stems are easy to obtain, this welding process is considered universal;

With the continuous improvement of equipment and welding rods, this welding method can always maintain a high quality of welding;

Slow welding speed and low efficiency;

Cleaning the slag is necessary after welding.

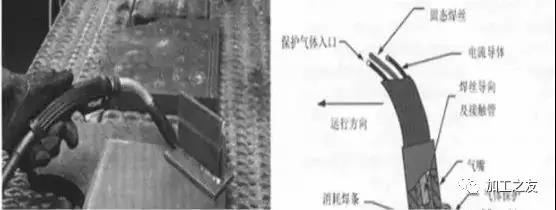

Gas protection arc welding (GMAW)

Arc welding protected by gas consists in continuously feeding the wires through welding pistols, and the heat of the arc generated between the welding wire and the part melts the basic material and the wire Welding, achieving the welding goal. A very important characteristic of arc welding protected by gas is that protective gases in the welding process are also transported by the welding gun, and these gases are inert and non -inert. Inert gases such as argon and helium can be used in certain welding, they can be used alone or in combination, or mixed with other non -inert gases such as nitrogen, oxygen or dioxide of carbon. Most of the gas protection arc welding use carbon dioxide as protective gas because it is cheaper than inert gas. The electrodes for arc welding by gas are solid nucleus welding wires.

Characteristics of arc welding protected by gas

1. High production efficiency;

2. Use gas to protect it without slag welding, and no cleaning of slag is required after welding;

3. Visibility of welding during welding, because there are no welding slag, the welder can easily observe the arc and the molten pool situation to improve control;

4. It is particularly sensitive to air flow and wind.

5. The requirements of the equipment are more complicated than manual arc welding equipment.

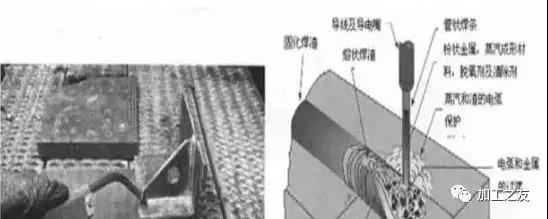

Flux kernel arc welding (FCAW)

Very similar to the gas protection welding, the difference is that the welding of the flow wire of flows uses a tubular welding wire, which contains a granular flow, rather than the welding wire of the solid nucleus used for protective welding of gas . The tubular welding wire is powered by the conductive nozzle in the welding gun and an arc is generated between the welding wire and the room. The welding metal is welded with a front welding, just like manual arc welding, and a layer of welding slag is covered on the welding metal. Depending on the type of wire used, additional protective gases may or may not be included for welding the flow nucleus. Some welding wires are designed to provide all the protection required by the internal flow, and they are called self -protection. Other welding wires require additional protective gases to provide additional protection.

Characteristics of welding the welding wire with arc welding flow:

1. Very high production efficiency, the most effective in the manual welding process;

That there is assistance with protective gas, the FCAW has greater tolerance to pollution with basic material than GMAW;

Due to the presence of flows, a large quantity of smoke will be generated during the welding process;

The cleaning of slag is necessary after welding;

The device is more complex than SMAW.

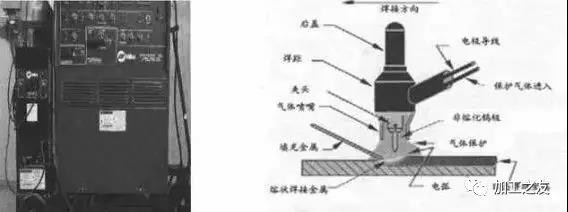

Welding with tungsten gas protection arc (GTAW)

The most important feature of GTAW is that the electrodes are not consumed during welding. It is made of alloy of tungsten or pure tungsten and has the capacity to withstand high temperatures, even high temperatures of arcs. Therefore, when the current passes, an arc is established between the tungsten electrode and the room. When the metal is required, additional additions should be added, generally by manual means or by mechanical wire power systems. The bow and metal are protected by inert gases which flow from the nozzles surrounding the tungsten electrode. Because there is no flow, the metal deposited does not require cleaning of slag. GTAW has a large application in many industrial fields. . Its unique cleaning and controllable properties make it the first choice for applications under demanding conditions such as space, food and pharmaceutical industries, petrochemicals and electricity pipelines.

Characteristics of the welding of the tungsten gas protection arc:

1. The main advantage is that welding welds have high quality quality and excellent quality of appearance;

2. Since there is no flow, this method is very clean and does not require cleaning of welding slag after welding;

3. Can weld extremely thin materials;

4. Suitable for welding almost all metals;

5. No filling material is required for welding;

6. Low production efficiency is the slowest of all the welding methods available;

7. Pollution tolerance is very low.

8. High requirements for the level of competence of welders;

9. It is easy to produce tungsten flaws.

Submerged arc welding (saw)

The saw is permanently fed with a welding wire with a solid nucleus, and the arc generated by the welding wire is completely covered by a layer of granular flow, it is therefore called the “submerged arc” welding. Highest typical welding method. For submerged arc welding processes, the granular flow is placed on the front or around the wire to protect the melted metal. During the welding process, there is a layer of welding slag and an always granular flow on the pearl.

Characteristics of submerged arc welding:

1. High merger efficiency;

2. There is no visible arc light, and the welder does not need to wear protective glasses and other thick protective clothes;

3. Generate less smoke than some other welding methods;

4. Welding can only be carried out when the flow can be supported in the welding, generally flat welding and horizontal welding;

5. The equipment is complex;

6. When using the flow, the flow must be heated and cannot be wet;

7. Cleaning slag is necessary after welding;

8. Solidification cracks that are easy to produce

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.