During the cutting process, thin walls are subject to cutting forces and are subject to deformation, resulting in phenomena of “size of size” such as ellipses or small media and large ends. In addition, due to poor thermal dissipation during treatment, thin walls are subject to thermal deformation and are not easy to ensure the quality of treatment of parts. The parts of the figure below are not only annoying to tighten, but also difficult to treat treatment parts.

▌ Process analysis

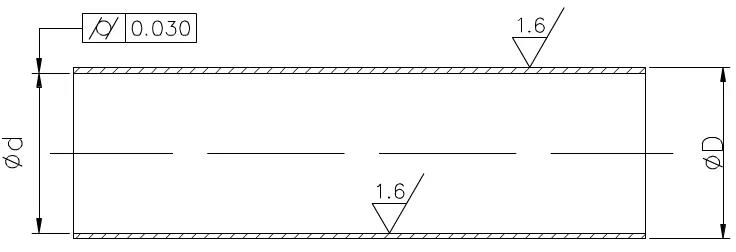

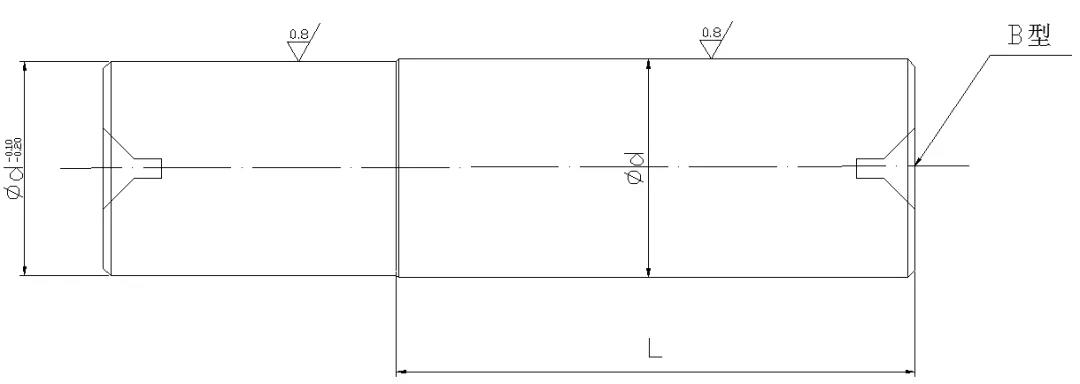

According to the technical requirements provided by the drawings, the part is processed using seamless steel pipes. 0.03 mm, which is necessary for parts with thin walls. In mass production, the process route is roughly: cut – heat treatment – Final side of the vehicle – Outdoor vehicle circle – Interior of the vehicle – Quality inspection.

The “Treatment of interior holes” process is the key to quality control. If we put aside the outer circle and the slim wall box, it is difficult to ensure a 0.03 mm cylinder when cutting the inner hole.

▌ Key technologies for vehicle holes

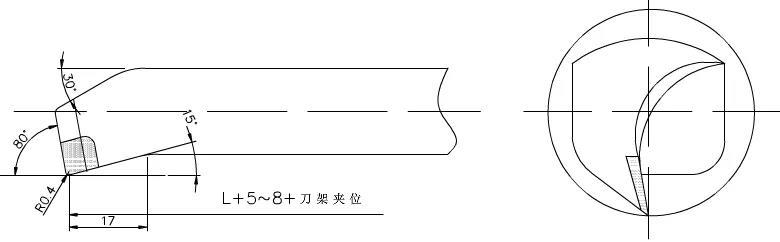

The key car’s bore of the car is to solve the problems of rigidity and elimination of the chips of the inner hole rotation tool. To increase the rigidity of the inner hole rotation tool, the following measures are taken:

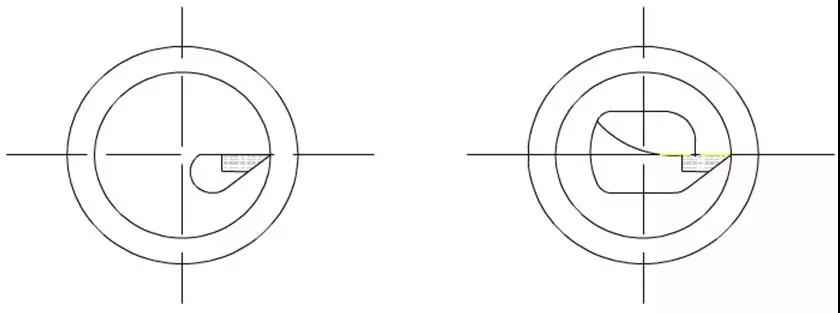

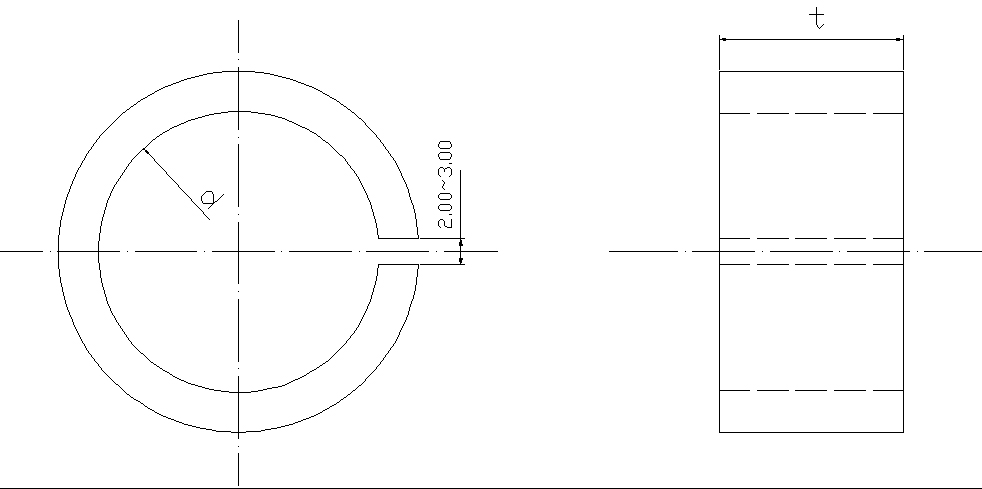

(1) Try to increase the transverse area of the tool holder. 1/4 of the transverse area of the hole, as indicated in the left figure below. If the point of the inner hole rotation tool is placed on the midline of the handle, the transverse area of the handle in the hole can be considerably increased, as indicated in the right figure below.

(2) The length of the stem of the tool extends up to 5 ~ 8 mm more than the length of the machining part, in order to increase the rigidity of the tool rod and reduce Vibrations during the cutting process.

▌ Solve flea elimination problems

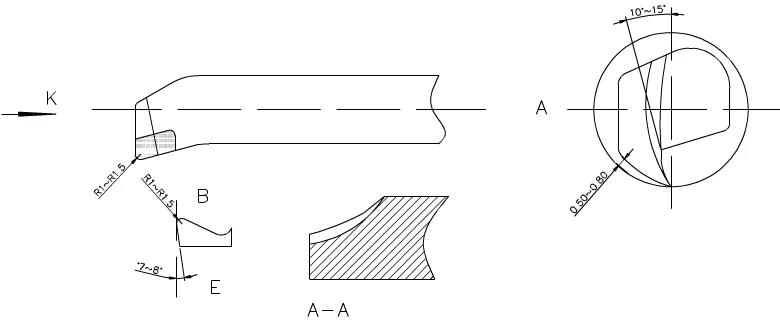

The cutting output management is mainly controlled. Figure below.

When you turn the cut edge, the chips are necessary to flow towards the centripetal front chip (hole core shavings). The arc towards the front edge. All good.

During grinding, the front angle is grinding at an arc -shaped angle of 10 ° -15 °. The peak angle K is §0.5-1 for fleas along the edge of the cut. The inner blade E is crushed to round the discharge of the chip outwards.

▌ Treatment method

(1) A guard must be done before treatment. The main objective of the holder of the tree is to cover the inner hole in the slim wall of the car with its original size, to fix it with the front and rear tips so that it can treat the outer circle Without deformation and maintain the quality and precision of the outside circle. Consequently, machining the tree is a key link in the process of processing sleeves with thin walls.

The round steel of the carbon structure of 45 ﹟ is used for the treatment of the bladder of the tree; After heat treatment, the grinding is fixed, then the remaining 0.2 mm are left. Reheat the crushed surface of the fire, the HRC50 hardness, then cringe it in the following figure by an external cylindrical shredder.

(2) In order to allow the treatment of the part at once, the hair is found with the clipping position and the cutting allowance.

(3) First, the heat treatment and conditions the explosion of the hair, with a hardness of HRC28-30 (hardness in the machining range).

(4) The rotation tool adopts C620. in the figure below.

In order to maintain mass production, one end of the outer circle of the thin wall box is transformed into a size size size D and T is an axial tightening position, and the thin wall box is in a hurry to improve the quality of the holes interiors and maintain the size. Given the occurrence of cutting heat, it is difficult to grasp the size of the room expansion. It is necessary to pour enough cutting fluid to reduce the thermal deformation of the part.

(5) Use the automatic seat with three sludge to firmly tighten the part, with the final side of the car and the interior circle of the car. Leave a margin of 0.1 to 0.2 mm and replace it with a fine turn tool to treat the cutting margin until the tree guard is too high and rough. Remove the inner hole rotation tool, insert the tree goalkeeper at the top front, tighten it with the upper tip of the tail seat as a function of length requirements, modify the rotation tool of the outer circle, Then respond precisely to the drawing requirements. After passing the inspection, cut it with a cutting knife depending on the size required of the length. In order to cut when the part is broken, the edge of the blade must be politely polished to make the final surface of the room flat; Reduces the deformation of the part, prevents vibrations and when reducing the reason for the fall and damage is damaged.

▌ Conclusion

The above method of processing the slim wall housing solves the problem of deformation or dimensional error and form that does not meet the requirements. The parts, and the size is easy to master.

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.