During the cutting process, since the front and rear blades of the turn tool are under severe friction and cutting heat, the cutting edge of the shooting tool will become dull and lose its cutting capacity. and correct the angle of the rotation tool.

Consequently, the rotating worker must not only understand the principle of cutting and reasonably choose the angle of the turn of turn, but also be competent in the dealer skills of the turn of turn. Let me ask you some experiences to sharpen the cutting tool!

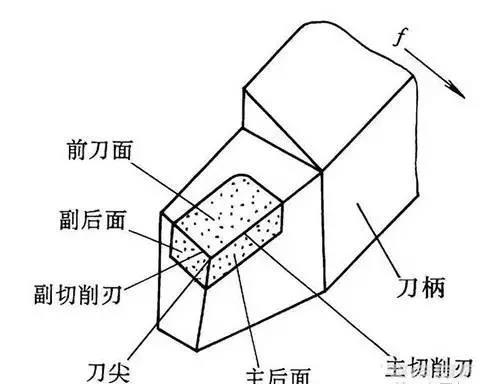

1. The composition of the turn

The turn tool consists of two parts: the head and the body of the knife. The cutting head is used for cutting and cutting body is used for installation. The knife head is generally composed of three sides, two edges and one point.

The surface of the front knife is the surface through which the chips flow.

The surface of the main rear tool is the surface opposite to the cutting surface of the part.

The side of the secondary backrest is the surface opposite to the treated surface of the room.

The main cutting edge is the intersection line between the surface of the front tool and the main surface of the tool, and is responsible for the main cutting work.

The secondary edge is the line of intersection between the front and the edge of the secondary back, which is responsible for a small amount of cutting work and plays a certain function of light repair.

The point of the tool is the intersection of the main slice and the secondary cutting edge, which is generally a small transition arc.

2. Formal structure of the turn

The most commonly used rotation tool structures are:

(1) Global rotating knife

The cutting part of the cutting head is obtained by sharpening.

(2) Welding knives

Weld the carbide blades to the head of the knife, and different types of turn tools can use different shapes of blades. Tool of rotation in welded cemented carbide, which can be used for high speed cut.

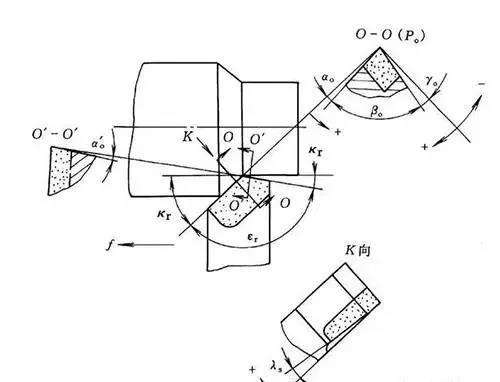

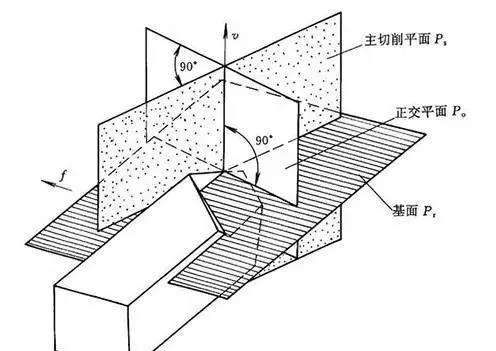

3. The main angle and the function of the shooting tool

The main angles of the turn tool include the front angle (γ0), the rear angle (α0), the main deviation angle (KR), the secondary deviation angle (KR) and the angle tilt of the edge (λS). In order to determine the angle of the rotation tool, three coordinate plans must be established: the cutting plane, the basic plane and the main section. For filming, if the influence of the installation of the turn of the turn and the cut is not taken into account, the cutting plan can be considered as a surface of the lead; The main cutting edge is the main section.

(1) The γ0 front angle is measured in the main section, which is the angle between the surface of the forefoot and the basic surface. Its function is to make the blade sharp and to facilitate the cut. But the angle in front should not be too large, otherwise the force of the blade will be weakened and it wears out or even collapses. When processing plastic materials, the front angle may be greater. The turn tool must be greater than approximate treatment to facilitate the sharpness of the blade.

(2) The posterior angle α0 is measured in the main section, which is the angle between the main posterior and the cutting plane. Its function is to reduce the friction between the main back and the room during the turn. is used.

(3) The KR’s main deviation angle is measured in the basic surface, which is the angle between the projection of the main cutting edge on the base surface and the power direction. Its function is:

1) The length of the main tip participating in the cut can be modified, affecting the lifespan of the tool.

2) influence the magnitude of the radial cutting force.

A small angle of main deviation can increase the length of the main section participating in the cut, so it dissipates better heat, which is beneficial to prolong the lifespan of the tool. However, when machining thin trees, the part is not rigid enough and a small angle of main deviation will increase the radial force acting on the part, which is subject to flexion and vibrations.

The mainly used main deviation angles of turning tools include 45 °, 60 °, 75 °, 90 °, etc., including more than 45 °.

(4) The KR secondary deviation angle is measured in the basic surface, which is the angle between the projection of the secondary cut edge on the base surface and the power direction. Its main function is to reduce the friction between the secondary edge and the processed surface to improve the roughness of the transformed surface.

Under the conditions where the depth of cutting AP, the quantity of power f and the main angle of deviation are equal, reducing the secondary deviation angle, KR can reduce the residual area after the turning point, thus reducing the roughness of the surface surface . ° Selected.

(5) The angle of tilt of the edge in the λS is measured in the cutting plane, which is the angle between the main cut edge and the base surface. Its function mainly consists in controlling the flow management of the fleas. The main edge is parallel to the base surface, λS = 0; Treatment; The tip of the tool is at the main edge, the highest point of λS is a positive value, the cutting point resistance is weakened and the chips flow towards the surface to be treated for the finish. The tilt angle of the turning edge λS is generally selected between -5 ° – + 5 °.

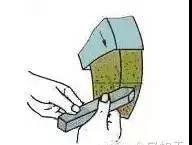

4. The grinding pale of the rotating knife

Once the tool of rotation is blinked, it must be sharpened to restore its reasonable shape and angle. The rotation tool is generally sharp on the crusher. Red of white alumina grinding for grinding steel turning tools at high speed and the green silicon carbide grinding wheel for carbide robbery tools of grinding.

When the rotation tool is taken up, the surface of the relevant tool is often crushed depending on the wear of the filming tool. The general order of turning the cut edge is: grinding the surface of the rear blade → crushing the surface of the secondary back blade → crushing the surface of the front blade → crushing the arc of the tip. Once the turned blade has been sharpened, the oil stone is used to finely grind each surface of the knife. In this way, the life of the filming tool can be effectively improved and the roughness of the room surface can be reduced.

The steps to turn the cutting edge are as follows:

Growing the surface of the main rear blade, and at the same time, the main deviation angle and the main angle of the main back are polite, as shown in the figure (A);

Grind the surface of the secondary back blade and grind the secondary deviation angle and the secondary of the secondary back at the same time, as shown in the figure (b) above;

Brush the front and grind in the front corner at the same time, as shown in the figure (C) above;

Growing each surface and the tip of the knife, as shown in the figure (d) above.

The posture and method of sharpening the turn tool are:

People stand on the side of the crusher to prevent debris from stealing and injuring people when the crusher wheel breaks;

Release the distance between maintaining the knife with both hands and tighten the waist with the two elbows to reduce the tremors when sharpening the knife;

When crushing the surfaces of the main and secondary back blade, the rotation tool must be placed in the horizontal center of the grinding wheel and the tip of the tool must be slightly increased by approximately 3 ° ~ 8 °. With the grinding wheel, he must move horizontally in the left and right directions. When the rotation tool leaves the grinding wheel, the rotation tool must be raised upwards to prevent the abrasive blade from being damaged by the grinding wheel;

When crushing the surface of the rear blade, the tail of the knife rod is tilted on the left by an angle of an angle of main deviation; a secondary deviation angle;

When sharpening the arc of the tip of the knife, the front end of the turn tool with the left hand is generally used as a support point and the tail of the turn of the right hand with the right hand is turned.

When sharpening the rotation tool, please pay attention to the following:

(1) During sharpening, keep the rotation tool firmly with both hands and look at the support to make the grinding wheel slightly. Do not use too much strength to avoid crushing the grinding wheel and causing an accident.

(2) The sharp turn tool should be moved to the left and right on the circumference of the grinding wheel to ensure that the grinding wheel is uniformly and not to leave the grooves. Avoid hard grinding of the turn of turn on both sides of the grinding wheel, and the grinding wheel will be swinging, saved or even broken.

(3) When the blade head is sharpened, it must be cooled by plunging water to prevent the head from aneangered and softening blade due to the excessive rise in temperature. When crushing a cemented carbide rotation tool, the blade should not be wet, in order to avoid cracks caused by the wet and cold blade.

(4) Do not stand in front of the grinding wheel to prevent the operator from being injured when the grinding wheel breaks.

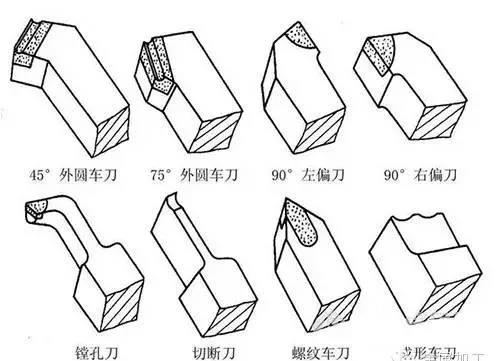

5. Current types and use of filming tools

The turn tool can be divided into an external circular turn tool, final facial rotation tool, cutting tool, drilling tool, rotation tool and pattern rotation tool, etc. depending on its goal.

(a) 90 ° turn tool (oblique knife)

(b) 45 ° turn tool (elbow rotation tool)

(c) Cut a knife

(d) Boredom tool

(e) Filming tool training

(f) Threaded turn

(g) The carbide does not go up the filming tool

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.