During the CNC Cup process, there are many reasons for machining errors. Treaty. In the event of real cut, the radial jump of the tool affects the precision of machining of parts, surface roughness, the wear and tear of unequal tools and the characteristics of the process of cutting multi-dent tools. The higher the radial jump of the tool, the more unstable the treatment state, the more the processing effect is affected.

▌ Causes of radial jumps

Manufacturing errors and components of the components of the tool and pin cause the drift and eccentricity between the axis of the tool and the ideal axis of spindle, as well as the technology of Specific treatment and tools, can cause radial jumps for machine machine tools during treatment.

1. The impact of the radial jump of the spindle itself

The main reasons for the radial pin jump error are the coaxiality error of each spindle journal, various errors of the rolling itself, the coaxiality error between the bearings, the deviation of the embroidery the method of treatment. These factors are formed in the manufacture and assembly of machine tools, and it is difficult for machine tool operators to avoid their impact.

2. The impact of the inconsistency between the tool center and the spindle rotation center

During the installation of the pin tool, if the center of the tool and the spindle rotation center are incoherent, this will inevitably lead to a radial jump of the tool. The specific influence factors include: coordination between the tool and the chuck, if the tool method is correct and the quality of the tool itself.

3. Impact of specific treatment technology

The radial jump caused by the tool during treatment is mainly because the radial cutting force exacerbates the radial jump. The radial cutting force is the component force of the total cutting force in the radial direction. It will be folded, deform and produce vibrations during treatment, and is the main component which affects the quality of the treatment of the part. It is mainly affected by factors such as the use of the cutting, the tool and the material of the part, the geometric angle of the tool, the lubrication method and the processing method.

▌ Methods to reduce radial jumps

The radial jump occurs during the treatment mainly because the radial cutting force aggravates the radial jump. Therefore, the reduction in the radial cutting force is an important principle to reduce the radial jump. The following methods can be used to reduce radial jumps:

1. Use sharp knives

Choose a larger tool to make the tool to make the tool clearer to reduce cutting force and vibrations. Select a rear angle of the larger tool to reduce the friction between the rear surface of the main tool of the tool and the elastic recovery layer on the transition surface of the part, thus reducing the vibrations. However, the front and rear angles of the tool cannot be too large, otherwise it will cause insufficient resistance and an area of thermal dissipation of the tool. Therefore, different front and rear angles of the tool must be selected according to the specific situation. more sharp tool.

2. Use solid tools

There are two main ways to increase the strength of the tool. First, the diameter of the tool rod can be increased by 20% when subjected to the same radial cutting force, and the amount of radial jumping of the tool can be reduced by 50%. Second, the length of the projection of the tool can be reduced. Will continue to change, causing the work room.

3. The front of the tool must be smooth

During treatment, the surface of the smooth front tool can reduce chip friction on the tool and can also reduce the cutting force exposed to the tool, thereby reducing the radial jump of the tool.

4.

The conical holes and mandrels of the spindle are clean and there is no dust or residue generated during the treatment of the room. When you choose machining tools, try to use tools with short extension lengths to apply the tool, the force must be reasonably and uniformly, and not too large or too small.

5. The selection of knife should be reasonable

If the tool is too small, the treatment will slide, which will constantly lead to the radial jump volume during treatment, which makes the surface treated and not smooth. Make sure that the tool deforms considerably, increase the amount of radial jumping of the tool during treatment and also make the transformed surface which is not smooth.

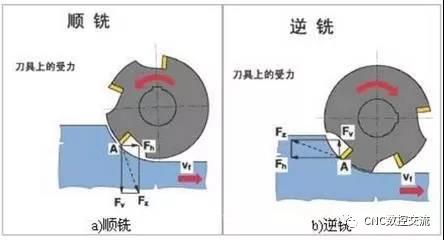

6. Use reverse grinding during finish

Since the position of space between the lead and the nut during grinding, it will cause an unequal diet of the workbench, resulting in an impact and vibrations, affecting the life of the machine and the ‘Tool and roughness of the document machining surface. , the cutting thickness goes from small to large, and the load on the tool also goes from small to large, which makes the tool more stable during treatment. Note that this is only used during the finish, and when you outline, you must always use a right milling, because the productivity of right milling is high and the lifespan of the tool can be guaranteed.

7. Use the cut of the fluid rationally

The rational use of the cutting fluid to make the cooling effect has little impact on the cutting force. The mainly lubricated oil cutting can considerably reduce cutting forces. Due to its lubrication effect, the friction between the surface of the tool-tool of the tool and the chips and between the surface of the rear cut and the transition surface of the part can be reduced, thus reducing the radial jump of the tool.

The practice has proven that as long as the accuracy of the manufacture and assembly of various parts of the machine tool is ensured and that reasonable processes and tools are selected, the impact of the radial jump of the tool on the Parting precision can be minimized as possible.

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.