Equipment produced by our company with a diameter of 500 mm, a dental width of 135 mm and a module of 14 were broken and failed during assembly and test test after treatment of heat and extinction And grinding teeth. The failure of the gear, we have analyzed and discussed the raw materials, the heat treatment processes, the transformation of the processing processes, the metallographic structures and the macro and micromorphs of cracks and determined the causes and the solutions for Fractures. On the one hand, the raw materials are strictly controlled, and by optimizing the heat treatment process, the part is normalized and soaked in a pre -treated, the grains are refined and the possibility of concentration of constraint is reduced, so as to further improve resistance to the fracture and tenacity of fracture of the material; After a period of practice, recurrence of fracture accidents was avoided, considerably increasing the reliability of the product and further improving the quality of the product.

1. Technical requirements and description of failure

Technical requirements of the gear: The material is 20crmnmoh to ensure the sustainability of the structure steel, the surface of the teeth must be fueled and extinguished, the hardness must be 58 ~ 62hrc, the effective depth of the hardening layer is 2.3 ~ 2.7 mm and the central hardness is 32 ~ 45hrc.

The flow of gear manufacturing process is: Forging → Standardization → Roaring cargo → UT defect detection → Cargais processing → drilling → Houving → Figs carburetor → shooting dossier → Internal grinding → flat grinding → teeth grinding.

The standardization process is: 900 ℃ isothermal temperature for 2 hours, and the oven is cooled by air.

The carburee process is: 760 ℃ isothermal temperature for 2 hours, then carbured at 930 ℃, and the oven is cooled at 830 ℃ for 2 hours.

The caliber and temperament process is: 650 ℃ isothermal temperature for 2 hours, then heat to 840 ℃ and keep it cool for 6 hours, and the oil is cooled at low temperature for 200 ℃ for 5 hours.

Description of the specific failure process: on February 16, 2012, a forging company provided the goods. Detection of defects of March 9, 2012, the vehicle processing unit was completed. 2012 The grinding, flat grinding and grinding teeth were completed in April 2, 2012;

2. Macro analysis

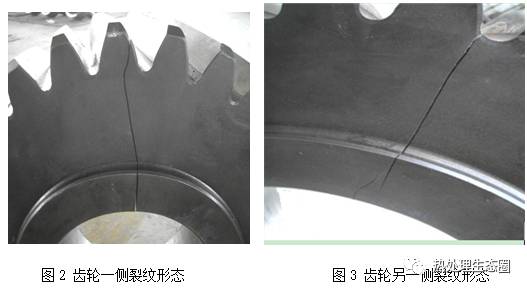

The macro-morphological distribution of gear cracks (see figures 2 and 3). Starts from the root and the inner hole respectively.

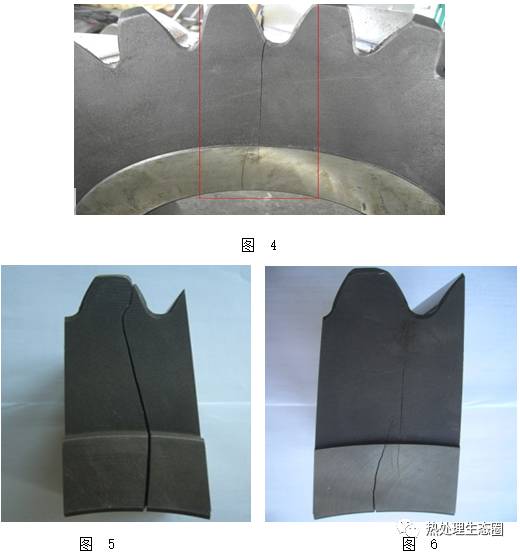

The sample was cut in the illustrated area for the inspection (figures 4 to 6).

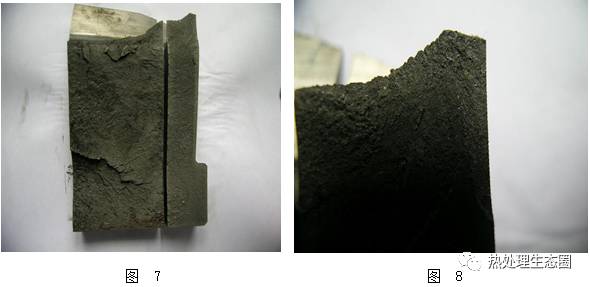

The sample was opened and observed. (Figures 7, 8).

After having amplified the sample, the transverse section was observed and found that the entire transverse section was formed after the development of several secondary cracks, and the initial crack source was at the nodes circle close to the surface. (Figure 9, Figure 10).

3. Quality material detection and heat treatment

(1) Analysis of the composition of the material of the material is presented in Table 1.

component | C | And | Mn | Crossing | Mo | Cu | P | S | B |

Require | 0.17 ~ 0.23 | 0.17 ~ 0.37 | 0.85 ~ 1.20 | 1.05 ~ 1.40 | 0.20 ~ 0.30 | ≤0.25 | ≤0.025 | ≤0.025 | 0.0005 ~ 0.0035 |

Real test | 0.179 | 0.278 | 0.958 | 1.108 | 0.224 | 0.008 | 0.007 | 0.00 | 0.00 |

After having sampled the body of the equipment for spectral analysis and detection, the test results were evaluated according to the GB / T 5216-2004 standard “ensure a standard of sustainable structure”.

(2) Detection of hardness of the gear, as shown in Table 2, the hardness of the tooth, the dental root and the core of the gear all meet the technical requirements.

project | Upper tooth surface | Root surface | Heart |

Standard value | 58 ~ 62 | 58 ~ 62 | 32 ~ 45 |

Real measured value | 58 | 58 | 42 |

Surface distance / μm | 200 | 400 | 800 | 1200 |

HV hardness value | 658.2 | 637.6 | 632.6 | 630.1 |

Surface distance / μm | 1600 | 2000 | 2380.7 | 2400 |

HV hardness value | 637.6 | 599.0 | 550.0 | 547.5 |

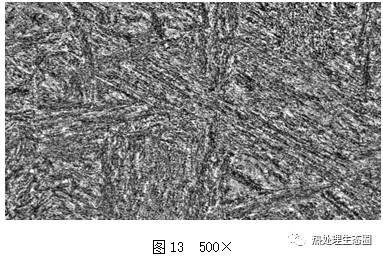

After corrosion, the sample had serious segregation (see Figure 13).

The central structure is the martensite of slats and the tissues in certain areas are thick.

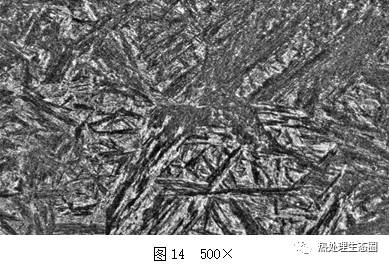

The underground structure is needle-shaped hammer, with a thick fabric in certain areas, and is assessed as level 7 according to JB / T 9211-2008 (see Figure 14).

The surface structure is the needle -shaped hammer, with small structures.

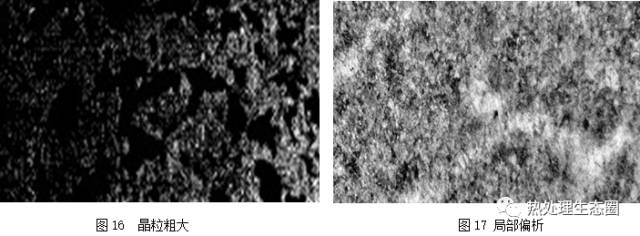

(5) Analysis of the metallographic structure of the standardized state before the carbureration and extinction of the gears. In order to verify more if there are quality problems with the raw materials of the gear, the author has carried out a sampling and an analysis based on the remaining dental white provided by the forge forge provider (see figure 17).

From the metallographic structure diagram of the nucleus of the standardized state, we can see that after the equipment is standardized, the nucleus structure grains are coarse and do not reach the purpose of normalizing and refining the grains . There is a phenomenon of local segregation.

4. Verification of the surface quality of the treatment of the rotation

In order to verify more that there may be quality dangers during the filming of the equipment or that there may be operations that do not meet the requirements during the turn, the author made a surprise inspection on several of the main cars processing units of the company. The results of the surprise survey confirm the previous judgment. . In this regard, the author took photos.

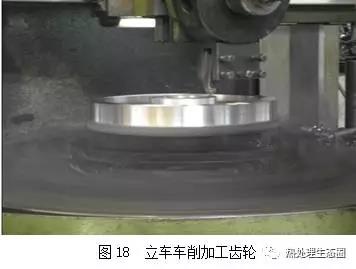

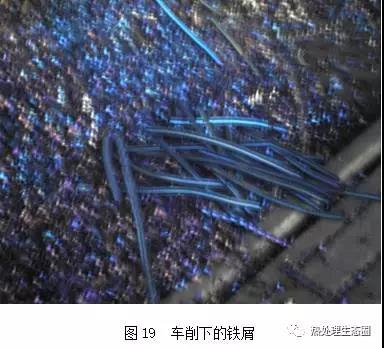

A truck processing unit runs and processes exit equipment on the vertical truck (see Figure 18). Steps. is used during the rotation process. The author asked the operator to turn on the cooling device switch, but no cooling liquid was seen going out. Shrank his hand, then checked the iron shavings that were turned (see Figure 19), the color has become blue, similar to high frequency caliber. , which shows the high temperature of the processing surface of the gear. It is obvious that the operator has seriously violated the procedures for operating filming treatment, causing changes in the surface structure of the room, considerably increasing the possibility of turning cracks on the surface.

In another vehicle processing unit, the author saw a similar situation: a 6140 Tour operator has shot and treated active equipment. , I also saw a tube of long cooling liquid rising high and firmly (see Figure 20). We can see that the coolant hose has become a decoration and does not play its due function. In addition, an operator partially poured the parts he had treated with a bottle of coke filled with cutting fluid …

The author immediately checked three gears for coloring and penetration detection.

The author immediately issued an opinion of serious non-compliance with the two cars processing units and ordered them to rectify within a period.

Analysis of rotating surface defects: during the cutting of metals, due to factors such as the material to the tool, the shape, the geometric angle, the hardness of the room material, the cutting speed, the quantity of Cutting and cooling conditions, rough surface marks often occur and precision and dimensions are not meeting the requirements. According to the results of the on -site verification, the failure of the failure is poorly used as a cutting fluid, resulting in a cutting deformation and an abnormal surface texture of the parts to be treated. The abnormal texture caused by inappropriate treatment of the cutting surface is essentially tiny cracks.

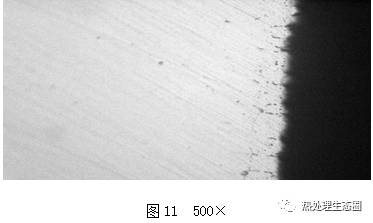

5. Experimental conclusion

By analyzing the composition of the materials, the detection of hardness and the depth of the effective hardening layer of the surface of the carburetor layer, we can see that the chemical composition of the gear, the surface hardness and the depth of hardening layer Effective carburetor layer all meet the requirements of technical drawings. However, from metallographic detection and analysis, the surface structure is needle-shaped hammer, with a small structure, and is noted in level 4 according to JB / T 9211-2008. And the fuel caliber process also meets the relevant technical requirements. The underground structure is the needle -shaped hammer, with a thick fabric in certain areas. does not meet technical requirements. The central structure is the martensite of slats, with a thick fabric in certain areas. Force and tenacity are important and internal stress is also important. However, samples have been taken from the circle close to the surface for microscopic examination and polishing observation, and a large number of net microcracks were present on the rotation surface, with a depth of about 0, 03 mm. We can see that there are certain problems with the quality of the turn surface. (The existence of the segregation of the molded parts of steel ingots causes different parts of the casting and even components in the crystal. The inconsistency leads to incoherent performance, easily forming the concentration of constraints, reducing mechanical properties, the Resistance to corrosion, the fracture of tenacity, the resistance to fatigue and the forge properties of the molded parts. Consequently, the reason for breaking the gear is that the equipment material has serious segregation, and the central martensite structure is thick and there are large internal constraints.

6. Quality improvement and control measures

According to the above analysis, we can see that the main reason for breaking the gears is that the material itself has serious segregation and that tissue grains are coarse and large internal stress. Failure to break the equipment.

To solve the above problems, the author improves mainly from two aspects: on the one hand, strictly controls raw materials and optimizes the pre-treatment process;

(1) strict control of raw materials and optimize the heat treatment process of parts

On the one hand, a strict control of raw materials is carried out, steel factories designated to buy raw materials and carry out relevant inspections and steel ingots tests, in particular the segregation tests of materials and control. On the other hand, by optimizing the heat treatment process to forge, normalize and temper the pre -treatment of the room, refine the grains, reducing the possibility of concentration of stress, in order to further improve the resistance to fracture and tenacity to the fracture of the material.

Strict control of raw materials: The raw material of the input equipment is made of steel 20CRMNMOH, to ensure a material in durable structural steel (GB / T5216-2004). In order to strictly control the quality of raw material steel ingots, forging suppliers must buy from the actor designated by our company to prevent raw materials from being purchased via informal channels, and steel ingots merged by degassing LF + VD empty are necessary. It also forces the supplier to add ultrasonic defect detection to steel ingots purchased in addition to inspection and conventional tests, and to focus on strengthening the analysis and detection of the segregation of materials. During the solidification process of steel ingots, homogenization and dissemination of alloy components cannot be carried out over time. In steel, elements such as carbon, sulfur, phosphorus, nitrogen, nickel, chrome, etc. All have a strong tendency of segregation, including the tendency of segregation of carbon, phosphorus and sulfur is the largest. On the basis of the various reactions to erosion by different components and different tissues, the use of appropriate erosion agents can clearly display the segregation of dendrites, and segregation can also be detected indirectly by microdature inspection. Regional segregation can be tested by macroscopic methods and the thermal acid corrosion test commonly used with an aqueous solution of hydrochloric acid 1: 1.

Optimization of the heat treatment process for forged parts: the molding of excessive parts of 20crmnmoh in steel generally uses traditional forging processes. During the heating process, the local temperature in the furnace is too high or the heating time is too long, and it is easy to form a large overheating structure inside the white. Three shots “or the equipment is small and the forging pressure is large. The overheating fabric is not sufficiently decomposed and will remain in the white of forge. The overheating of the tissues will result in a considerably reduction of the forge to reduce the Mechanical properties such as elasticity limit, tensile resistance, elongation, narrowing of the transverse section, tanticia in impact, etc., which seriously affects its life of fatigue and safety of use .

In addition, steel forging is heated in the Austenite region. Grain seals, while the temperature and cooling speed will form overheated structures in different states. For too fast or too slow cooling speed, there is no precipitation of second phase particles where there is an overheated structure with precipitation and larger particles aggregation belonging to an overheated non -stable structure . .

On the basis of the above reasons, the original forging standardization process has been improved: 900 ℃ isothermal temperature for 2 hours, the furnace was cooled at 600 ℃ for 2 hours and the furnace was cooled in the pot . In addition, the forging body sampled in the standardized and temperate state is taken to carry out mechanical performance tests to verify that its elasticity limit, its resistance to traction, its elongation, its transverse narrowing and its tenacity to the ‘Impact meet the requirements.

(2) Check the surface quality of the shooting treatment

In order to strengthen the effective control of the surface quality of the treatment of the gear turn, the author carried out the following two aspects of the control: on the one hand, a complete rectification was carried out for the processing unit of external vehicles , and all the filming equipment was equipped with a coolant system. From the author, add MT and PT inspections during the purchase inspection and use non -destructive tests to control fine cracks on the rotation surface.

7. Conclusion

To summarize, when a company products have quality problems or fail in the manufacturing process, how to effectively analyze causes, formulate corresponding corrective and preventive measures and carry out effective quality control is the key to management of business quality. Thanks to various methods of inspection and testing and investigation in the field and research analysis, the author discovered the reasons for the failure of the corresponding equipment and improvement measures proposed. After a period of practice, significant results have been obtained, avoiding recurrence of fracture accidents (no problem of similar quality has occurred in recent years), thus considerably increasing the reliability of the product and further improving the quality of the product .

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.