Given the phenomenon of parts on the sur-distance caused by roundness errors which often occur during machining centers during machining, in order to avoid such problems, the reasons for the errors of roundness are analyzed and How to delete these problems in the real treatment of the machine tool. To guarantee the accuracy of the required parts.

The roundness error refers to the quantity of change of the real circle of the object to be measured in the same transverse section of the rotary body with the ideal circle. During the long-term use of CNC machine tools, ball screws, guide rails and bearings have more or less wear to a certain extent. Mechanical components will be aggravated, causing an accelerated deterioration of CNC. The dynamic response of the CNC system is unstable and the optimization of the servo is incomplete, which will also affect the roundness error of CNC machine tools.

Generally, in the actual application of machine tools, the roundness error detection of the processing equipment can be carried out via the club or the test of the roundness of the equipment. The roundness test function of the CNC Siemens 840DSL system can measure the real and theoretical roundness errors of the tool machine without having to cut parts tests, via the treatment of the CNC program simulation, and combined with the powerful Calculation capacity and the position of position of position of the function of the function of the position of the position of the rear function of position of the function of the function of the position of the position of the function of the position of the position of The position of the position of the position of the CNC position The CNC system, the real and theoretical roundness errors of the tool-machine can be measured by the matching of the analyzing different figures obtained by rounding test, the causes From different errors and the adjustment methods of such errors can be obtained. Generally, the main reasons for roundness errors are the large inverted gaps of the interpolation shaft, the opposite jump, the degreen of the servo, the non-vertical interpolation trees and the vibrations of the machine tool. The following is an example of the CNC Siemens 840DSL system.

1

Reverse deviation error

The reverse space for the machine-tool refers to the fact that when a certain axis of the machine-tool passes from the movement forward to reverse the movement during the movement, at a certain angle, although the Driving engine leads to the screw to reverse, work work still needs to wait for the screw. CNC system in closed loop, the axis is between the control value and the real quantity of movement when it moves upside down.

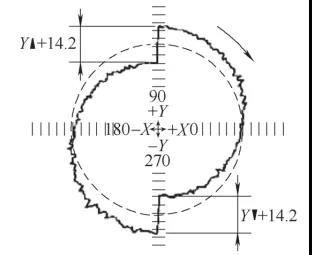

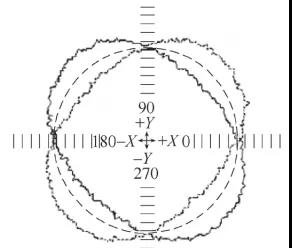

(1) The impact of the opposite space on the error of the roundness The existence of the inverse space will affect the positioning accuracy and the precision of positioning the repetition of the machine tool, will reduce the accuracy of Machining of CNC machine tools and causes roundness errors during the central machining grinding process. When the axis is in the opposite movement, due to the existence of the opposite space, the axis will be lagging behind the X axis for the interpolation movement, and the treatment of the grinding circle will appear as indicated in Figure 1.

Figure 1 Rondeur error caused by reverse space

(2) The measurement and adjustment of the reverse clearance affect the reverse clearance error of the axis of the machine. The ball screw, that the pre-tower of the screw is too close or too loose, and that the wire master and the mobile parts are well connected are all the reasons for the reverse space between the rod of the machine-tool . For gaps that cannot be eliminated by the mechanical part, the opposite difference must be offset in the CNC system.

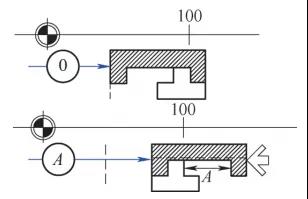

As shown in Figure 2, perform the reverse space measurement, use a magnetic meter support to fix a position, press the head of the dial meter on the treating to be measured at a fixed position, the scale of the scale Dial counter is adjusted to zero and continue to move in the same direction, the power axis is a certain distance, move the axis towards the back towards the initial position, read the difference A of the dial meter and The average value obtained after 7 measures is the reverse space error of the axis, that is to say, a = (A1 + A2 + A3 + A4 + A5 + A6 + A7) / 7. The Writing the calculated value measured A in the MD32450 parameter of the corresponding axis can eliminate the opposite difference from this axis. By compensating for the reverse clearance of the tree, the precision of the power tree can be effectively improved to guarantee the accuracy of the interpolation movement and effectively improve roundness error.

Figure 2 Measurement of the reverse deviation

2

Vibration of the machine tools’ supply shaft

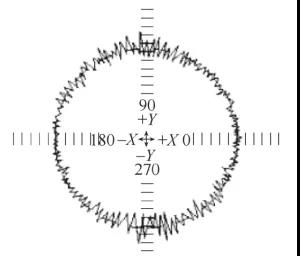

The vibrations generated during the treatment of CNC machine tools will not only affect the dynamic accuracy of the tool-tool, but will also reduce the precision of the contour of the machining parts, increase the value of surface roughness and even affect the lifespan tool and machine tool when the vibration is severe. (1) The causes of vibration and their impact on roundness errors. Easy to cause the ramp and vibrations of the power tree; the position, the speed ring and the current and acceleration ring, etc. Unreasonable parameters cause the system oscillation. During the application of CNC machine tools, the causes of vibration are generally complete and must be checked one by one. As shown in Figure 3, when the axis of the machine supply of the machine vibrates, the tool and the part will jump periodically and the room vibrates at random, and the precision of the part of the room and the surface roughness will be affected .

Figure 3 Rounder error caused by the vibration of the axis

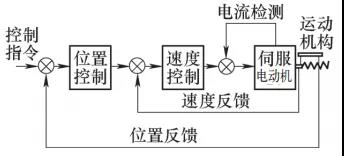

(2) Methods of removing the vibrations of the power tree in the CNC machine tools, the inadequacy between electromechanical systems generally causes vibration of the axis of machine tools. Dynamic performance. As shown in Figure 4, the servo reader of the axis of the machine-tool includes three feedback loops, namely the position loop, the speed loop and the current loop. When the power tree vibrates, first check if the mechanical system has good lubrication and the transmission chain has sufficient rigidity; The gain parameter 1407 is optimized manually until the servo axis is depressed and the movement is stable.

Figure 4 Block diagram of the Servo system

3

Axis of interpolation Servro Gain Ciscottre

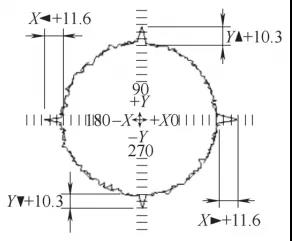

The distances of each axes should be exactly the same during the cycle to operate a circle. If the strawberry circle becomes an ellipse, as shown in Figure 5, this means that the major axis is ahead of the minor axis during the interpolation movement. For machine tools that have been used for many years, the first thing to do is to inspect the mechanical structure of the tool for the machine-tool, if the transmission device is loose and if wear is serious, check the lead pre-tower screw and bearing for the clearance of the clearance and compensate for the reverse clearance. .

Figure 5: The gain causes incoherent causes

4

Reverse jump

The reverse jump means that when a certain axis of the tool-tool moves in the opposite direction, the axis accelerates a negative speed at a positive speed, and when the speed of the axis goes by 0, the state of friction goes from static friction to dynamic friction. The required force is greater than that during normal movement, resulting in a short period of viscous break in switching due to the change in the state of friction.

(1) The impact of the reverse error on the roundness error during the milling process of the central machining circle, when the axis passes through the quadrant, the speed direction of the axis changes , the axis begins from zero speed and the state of friction changes accordingly, which must exist. When one of the two interpolation areas reached its maximum value and the other is 0, there will be a short stagnation, resulting in a contour error. As shown in Figure 6, the circle has 4 pointed corners in the quadrant, which is the reverse jump error caused by static friction.

Figure 6 Rondeur error caused by a reverse jump error

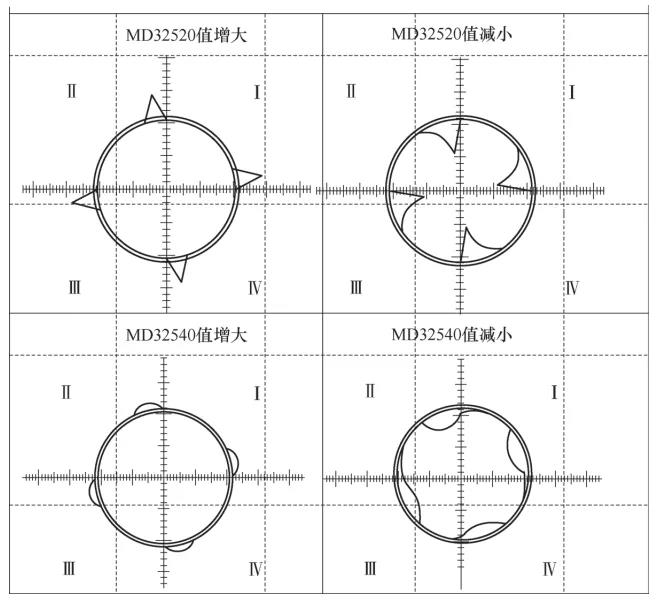

(2) Reverse jump adjustment method The main reason for the reverse jump is the change in the friction state, so when a reverse jump occurs, friction compensation must be added to the interpolation axis. MD32520 compensation value and the constant friction compensation time MD32540.

For the adjustment of the reverse jump, first define MD32500 = 1 (the friction compensation is valid), then adjust the md32520 friction compensation value and the constant friction compensation time MD32540 corresponding to the jump axis. The two parameter values. It should be noted that the compensation value should not be too large. Friction compensation can be a negative impact on the quality of the surface.

Figure 7 Front compensation reference

5

Conclusion

CNC machine tools are a complete organic set, and mechanical, electric and hydraulic control is interconnected and influenced by others. Consequently, during the analysis and resolution of factors that affect the roundness error, you must have global concepts and experiences, carry out tests, an analysis and a diagnosis with multiple facets until the deep cause of the fault is found.

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.