1 Preface

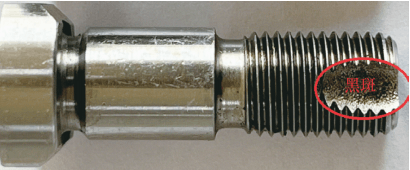

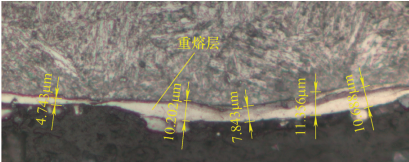

After the crescent-shaped groove of an engine bolt was processed by EDM, black spots and recast layers appeared on the surface. The location of the black spots on the surface is shown in Figure 1, and the recast layer is shown in Figure 2. The material of the bolt crescent groove is made of round bar upheaval blanks, which are produced by rough turning → fine turning → thread rolling → electric discharge machining and other processes.[1]。

Figure 1 Location of black dots on surface of crescent bolt groove

Figure 2 Recast layer of bolt crescent groove

2 Problem analysis

2.1 Brown spots

EDM treated bolts tend to leave black spots. This is generally referred to as carbon deposition during the EDM process. This is due to the uneven phenomenon on the surface during the machining process, which will accumulate the carbides attached to the surface, and the removal channels of the carbides generated during the machining process are not clear. smooth ; and the chip removal and cooling conditions are different; in addition, the formation of an accumulated edge on the surface of the crescent-shaped groove increases the difficulty of chip removal, resulting in the appearance of black spots.

2.2 Recast layer

The surface layer of the crescent-shaped bolt groove after EDM processing is subjected to a high instantaneous temperature of about 10,000 °C and the cooling effect of the liquid medium.[1]its chemical composition and its physical and mechanical properties have undergone some modifications. These changes have a negative impact on the quality of EDM machined bolts and their performance.

The recast layer is located on the upper layer of the crescent groove surface of the bolt after EDM processing.[2]. It is melted by the instantaneous high temperature generated by the electric spark pulse discharge and solidified by the rapid cooling of the surrounding working fluid. It is completely different from the structure of the die metal (base metal) and is a dendritic quenched casting structure.

Generally speaking, the thickness of the EDM reflow layer is related to the type of bolt material and the electrical parameters of EDM processing, that is, the larger the pulse width, the greater the thickness. The thickness of the reflow layer is large.

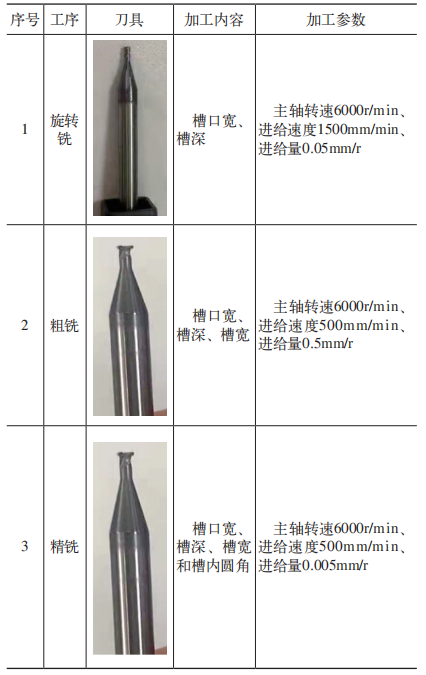

3 Improvement of bolt crescent groove processing technology

Since EDM produces metal melting at high instantaneous temperatures, black spots and recast layers of electrical corrosion on the crescent groove surface of the processed bolt negatively impact the quality and performance of the bolt and cannot be avoided. After discussion, it was decided to use high-speed milling technology instead of EDM technology to process the crescent-shaped bolt grooves. Processed using special special cutters during CNC milling[3]using the “special CNC program and three-step method” of rotary milling → coarse crescent groove milling → fine crescent groove milling to improve the processing quality. Bolt crescent groove processing tools and parameters are shown in Table 1.

Table 1 Bolt crescent groove processing tools and parameters

4 Treatment effect

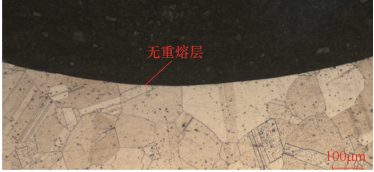

Through process improvement, EDM machining has been replaced by high-speed CNC milling. The processed bolt crescent groove surface has no black spots (see Figure 3), and there is no recast layer after metallographic inspection (see Figure 4).

Figure 3 There are no black spots on the surface of the crescent bolt groove after process improvement

Figure 4 There is no reflow layer in the crescent bolt groove after process improvement

5Conclusion

Since EDM machining of bolt crescent grooves cannot avoid the occurrence of black spots and recast layers, which will negatively affect the quality of bolts and their performance, so we should change our thinking , take full advantage of the advantages of the equipment and. use high speed CNC milling instead of EDM. Through batch processing verification, the problems of black spots and recast layers can be completely solved, ensuring the quality of bolt processing.

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.