What is the benchmark for?

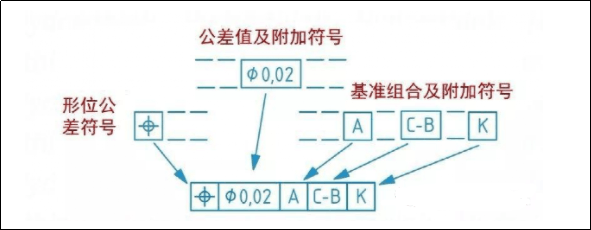

When we look at a typical geometric tolerance label, we will definitely notice a box with letters behind it. This is the “reference system” of tolerance.

But why do we need benchmarks? Please answer one question first: How tall is Mount Everest?

Yes, why is altitude so important, because it marks and defines the starting point of the measurement!

Altitude is measured from sea level to zero, so sea level is the reference here.

Let me ask another question: how many steps does it take to measure a person’s height?

Both the platform and the ruler are references here, which are references introduced to ensure the uniqueness and accuracy of the measurement. Therefore, we can summarize that the benchmark has two main functions:

Provide an origin or reference for the measurement

Constrain the placement of the tested objects

After understanding the role of benchmarks, several concepts still remain to be distinguished:

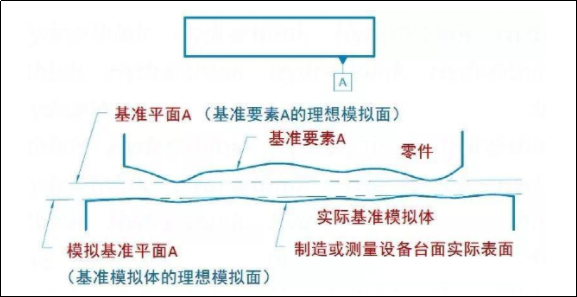

Reference: Ideal geometry used to position or constrain parts, such as points, lines, planes, etc. It should be noted that the data is a virtual geometry and does not exist on any physical object. For example, the sea level just mentioned is an ideal surface adjusted by calculations, rather than the actual sea surface;

Datum Feature: The actual feature corresponding to the datum on the part, such as the datum symbol A marked on the part drawing. To be precise, the actual surface it points to is the reference function A. Or as in the example just mentioned, the data element corresponding to the data “sea level” is the rough surface real of the sea;

Reference Simulator: The actual geometry used to simulate the reference in the measurement or processing system, such as the workbench of the processing or measurement equipment, special inspection devices, etc. Their tolerances are much smaller than those of the parts, so they are different from the ideal shape. The difference can be ignored, so we can usually approximate the actually acting part of the reference simulation body as a reference. For example, the platform area used for the height measurement mentioned above is the actual area of a reference simulation body. Usually we just call it the reference directly;

Simulated reference: The ideal geometric elements matched to the actual functional parts of the reference simulation body are actually equivalent to the reference display on the reference simulation body.

These concepts may be a bit abstract, but it doesn’t matter if you understand them slowly, they will not affect our later understanding of knowledge.

How benchmarks work

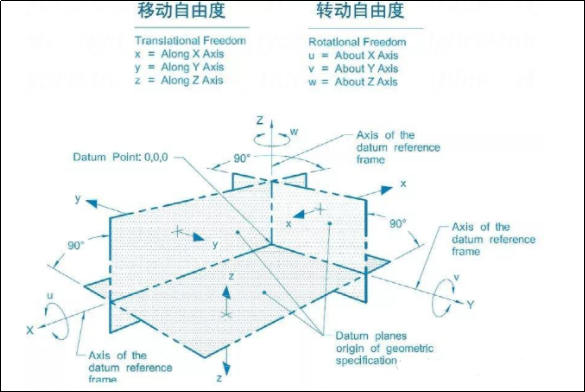

As we just mentioned, one of the functions of data is to constrain the placement of parts. We know that an object has six degrees of freedom in three-dimensional space. If we place this part in a three-dimensional Cartesian coordinate system, these degrees of freedom It can be represented by x,y,z,u,v,w.

When we use a piece of data to completely constrain a part’s six degrees of freedom, it is also completely constrained. But it is not necessary to completely constrain the parties in every situation, provided that reasonable constraints are selected based on the needs of the function.

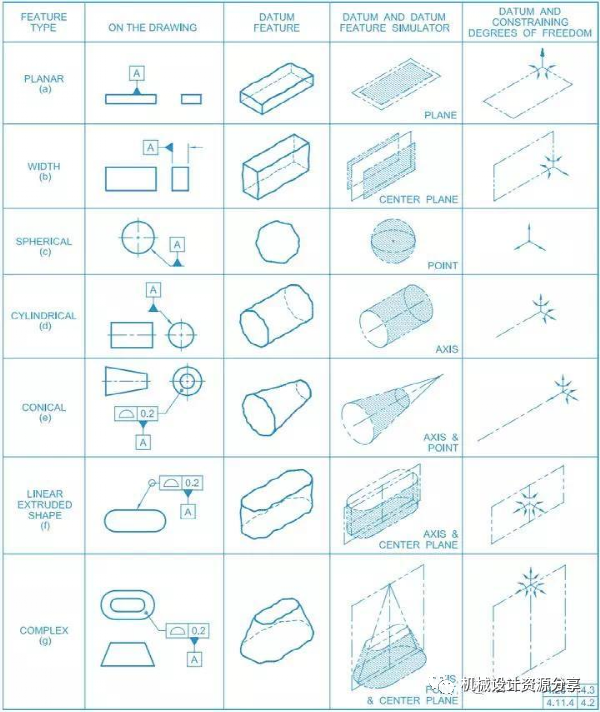

The following table (taken from ASME Y14.5-2009) lists some commonly used reference characteristics and the degrees of freedom they can limit:

In this article, we briefly present the role of benchmarks. As for where the benchmark comes from and how it works, can we understand it through an example? This is very important for mechanical engineers, process, quality and measurement personnel. As long as you deal with drawings, you can’t avoid it.

This completes the explanation of the mechanical drawing and you are welcome to add to it.

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.