A Comprehensive Guide to A Part On A Robot Used Like A Gripper Name

Robotic systems have revolutionized industries across the globe, and one of the most vital components in these systems is the gripper. Grippers play a pivotal role in enabling robots to interact with their environment, and understanding their origin, purpose, materials, and development is crucial for industry professionals. This article provides an in-depth look at grippers and explores the wider context of robot parts.

The Origin of Gripper Technology

Grippers, sometimes referred to as end-effectors, are mechanical devices used to grasp and manipulate objects. The concept dates back to early automation and industrial robotics in the mid-20th century when manufacturers sought ways to enhance productivity by reducing reliance on human labor for repetitive tasks.

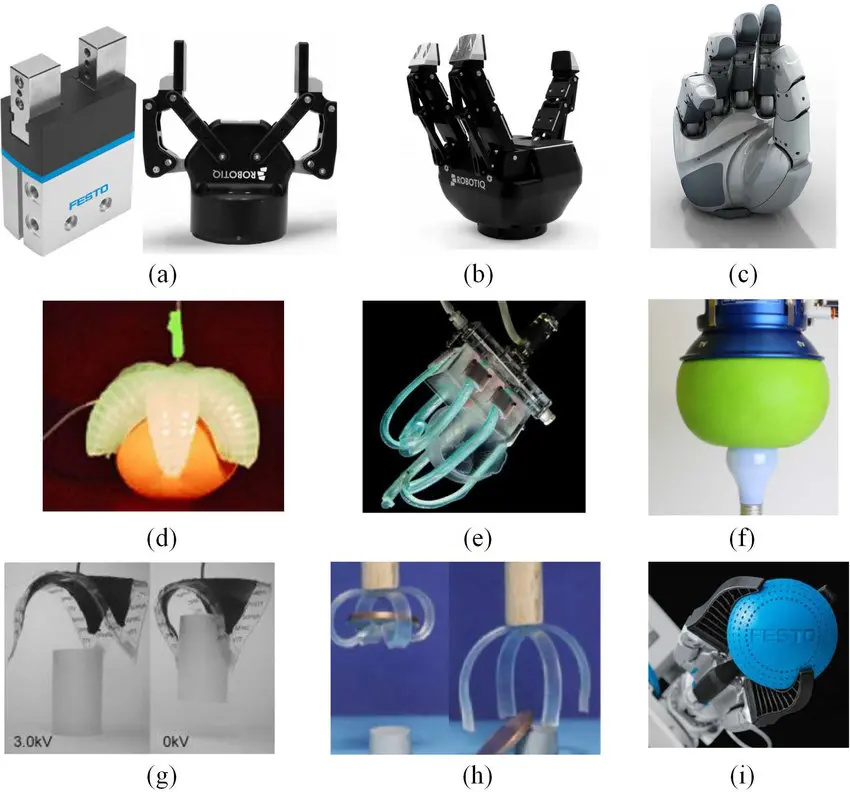

Initially, grippers were simple mechanical clamps, but advancements in engineering and material science have led to the development of sophisticated designs such as parallel grippers, vacuum grippers, and even soft robotic grippers that mimic human hands.

Purpose and Functionality of Grippers

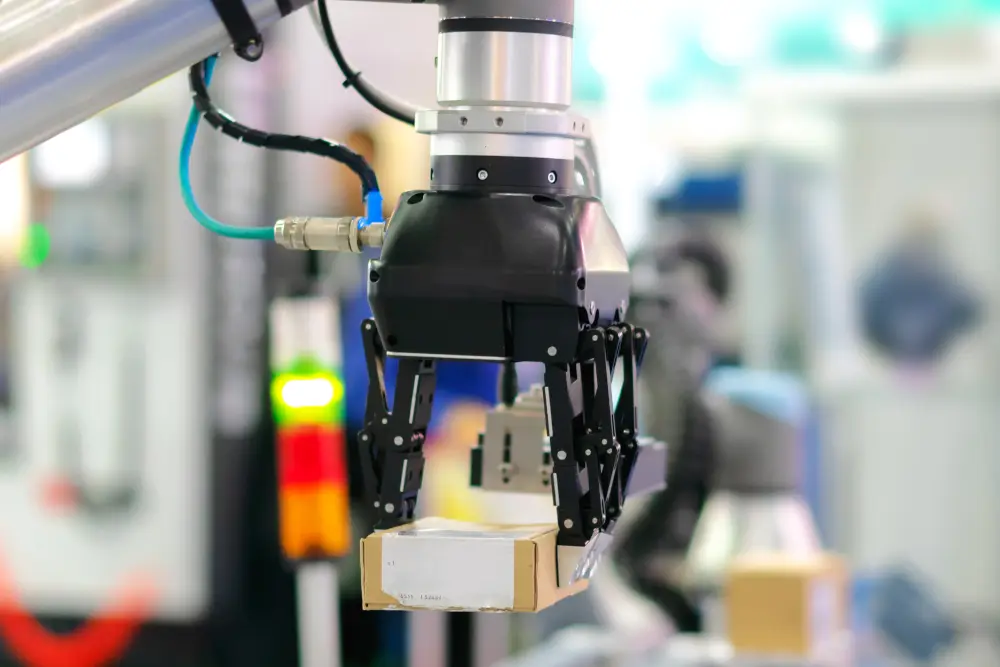

The primary purpose of a gripper is to enable robots to securely hold, move, and manipulate objects during operations. Their functionality spans numerous industries, including:

- Manufacturing: Handling components during assembly processes.

- Healthcare: Assisting in surgeries and handling delicate medical instruments.

- Logistics: Picking and placing packages in warehouses.

- Agriculture: Harvesting crops with precision and care.

- Automotive: Assembling parts on production lines.

Industry Characteristics and Usage Scenarios

Grippers are indispensable in scenarios where precision, speed, and repeatability are paramount. Here are some key usage scenarios:

- Pick-and-Place Operations: Common in assembly lines and packaging industries.

- Material Handling: Moving heavy or fragile materials in warehouses.

- Inspection: Manipulating objects for quality control purposes.

- Precision Assembly: Used in microelectronics and other industries requiring high accuracy.

Future Development Directions for Grippers

The future of gripper technology is poised for exciting advancements:

- AI Integration: Incorporating machine learning to enhance adaptability and efficiency.

- Soft Robotics: Development of grippers capable of handling irregular and fragile objects.

- Material Innovation: Utilizing lightweight, durable, and cost-effective materials.

- Energy Efficiency: Reducing power consumption through advanced actuators and control systems.

Key Robot Parts: A Detailed Breakdown

To understand how grippers fit into the larger robotic system, it’s essential to examine the primary components of robots. Below is a comprehensive table outlining the main robot parts:

| Robot Part | Material Used | Performance Requirements | Main Processing Methods |

|---|---|---|---|

| Gripper (End-Effector) | Aluminum, Steel, Polycarbonate | High precision, durability, light weight | CNC Machining, 3D Printing |

| Actuator | Stainless Steel, Aluminum | High torque, reliability, compact size | Casting, CNC Machining |

| Controller | Plastic, Copper, Silicon | Fast processing, reliability | PCB Manufacturing, Assembly |

| Sensor | Silicon, Glass, Plastic | Accuracy, sensitivity | Injection Molding, Etching |

| Power Supply | Aluminum, Plastic | Efficiency, stability | Die Casting, Injection Molding |

| Frame | Aluminum, Carbon Fiber | Strength, lightweight | Welding, CNC Machining |

| Wheels/Tracks | Rubber, Steel, Plastic | Durability, traction | Injection Molding, Casting |

| Joints | Titanium, Aluminum | Flexibility, strength | CNC Machining, Assembly |

Great Light: Your Trusted Partner for Custom Robot Parts

As a leading supplier of custom robot parts, Great Light leverages cutting-edge 5-axis CNC machining technology to provide tailored solutions for every industry. Our expertise extends across:

- High-precision manufacturing.

- Custom designs to meet unique operational requirements.

- Comprehensive post-processing and finishing services.

- A wide range of materials, including aluminum, titanium, stainless steel, and more.

At Great Light, we ensure top-tier quality, swift production, and competitive pricing, making us the first choice for custom robot parts.

Conclusion

Grippers, as essential robotic components, embody the intersection of innovation and functionality. Their evolution mirrors the broader advancements in robotics, showcasing how tailored design and cutting-edge materials can address diverse industrial needs. For all your custom robot part requirements, trust Great Light to deliver unmatched quality and precision.

Customize your robot parts today to drive efficiency and innovation in your operations!