In the manufacturing industry, someone once estimated that there were more round parts than flat parts, ranging from screws, nuts and washers to cylinders and bearings. The application of circular shapes is indeed very widespread.

Examples of measurements for round parts

For these rotating parts, the most pressing problem to solve is how to assess their true round “shape”. Today I will present to you the symbols and definitions related to roundness (reference standards: ISO/DIS 1101:2017, ISO 5459).

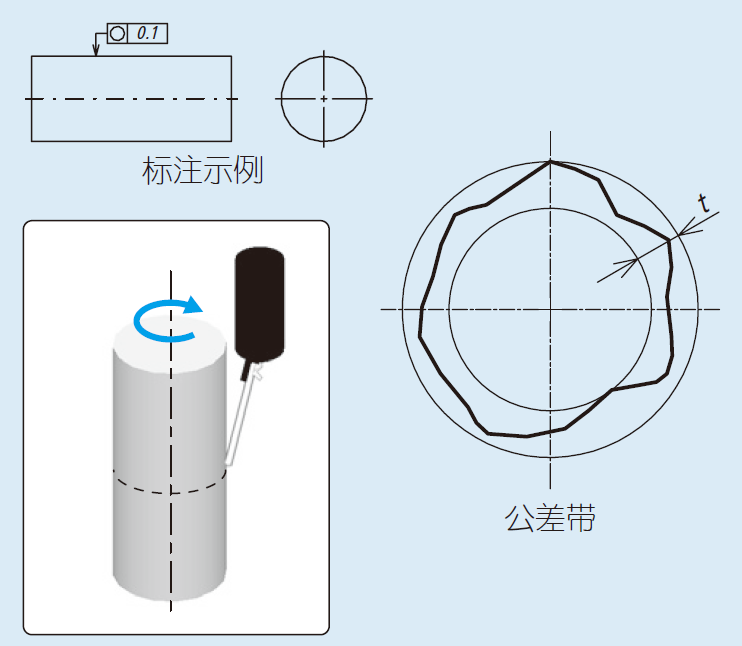

Roundness

The extracted circle must be limited to the tolerance zone between two coplanar concentric circles whose radius difference is t.

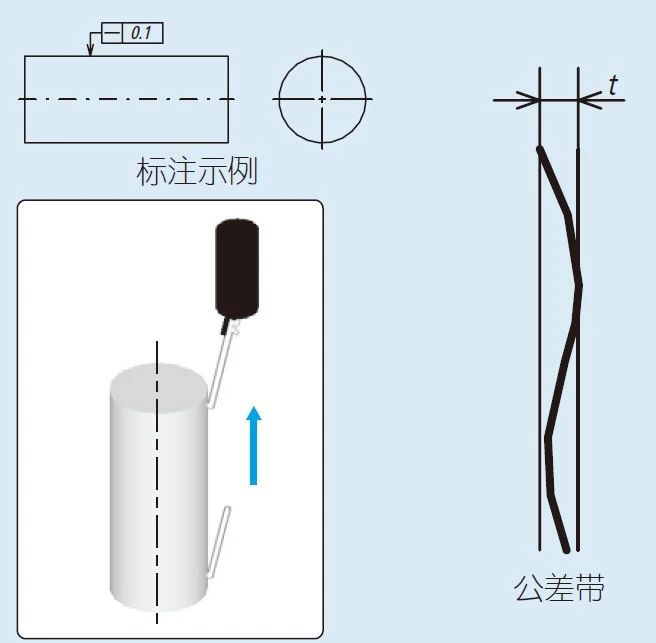

Straightness

The edges extracted from the cylindrical surface must be limited to the tolerance zone between two parallel lines in the specified direction and with a distance of t.

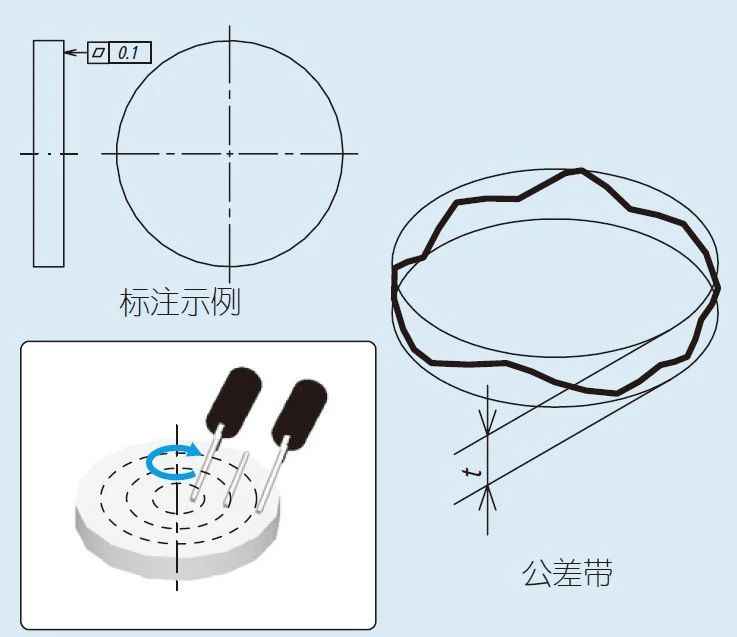

Flatness

is the area between two parallel planes whose distance is the tolerance value t.

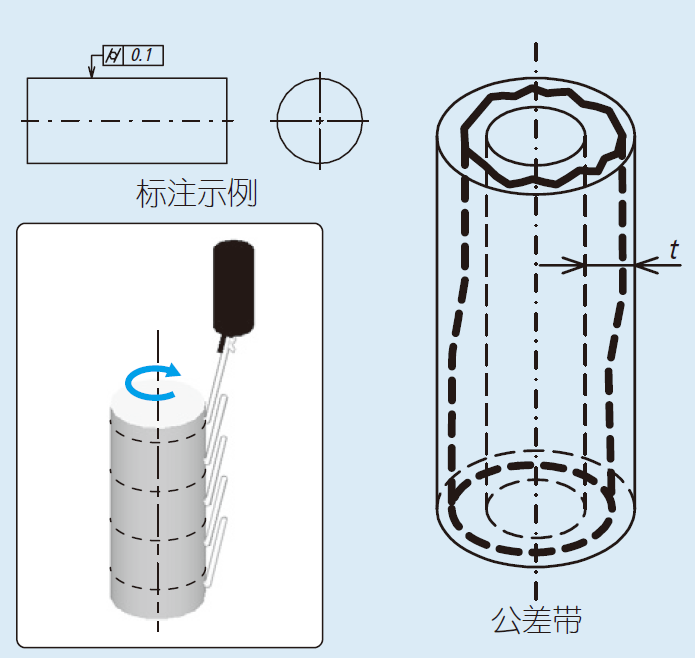

Cylindricity

The extracted cylindrical surface must be limited to the tolerance zone formed between two coaxial cylindrical surfaces with a radius difference of t.

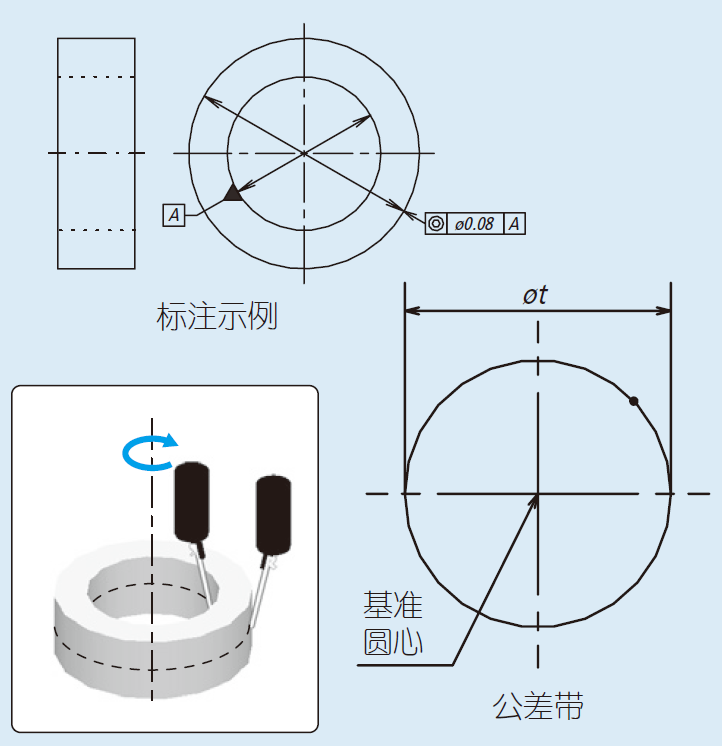

concentricity

The extraction center of the circle must be limited to the tolerance zone formed by the circumference of the circle of diameter t concentric with the data.

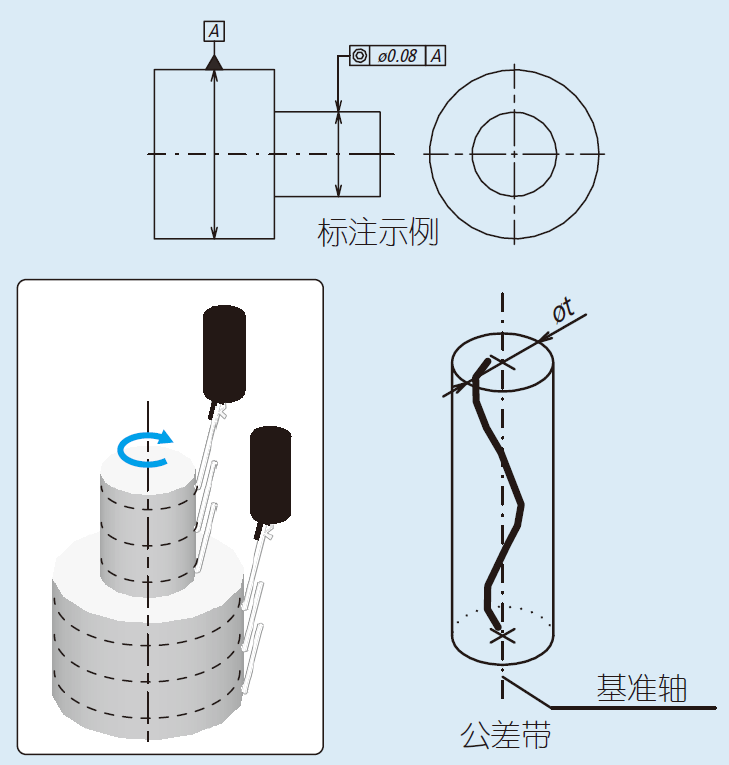

Coaxiality

The extraction axis must be limited to the tolerance zone formed by a cylindrical surface of diameter t coaxial with the reference.

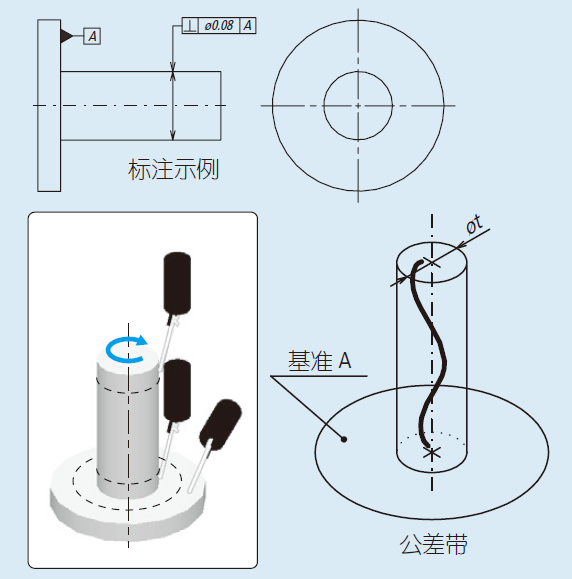

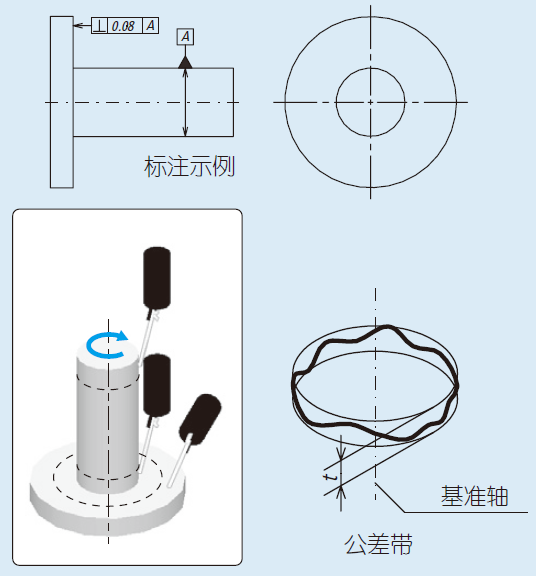

Verticality

The extraction axis must be limited to the tolerance zone formed by a cylindrical surface of diameter t and perpendicular to the reference plane.

The extraction surface must be defined in the tolerance zone formed between two parallel planes spaced t and perpendicular to the reference axis.

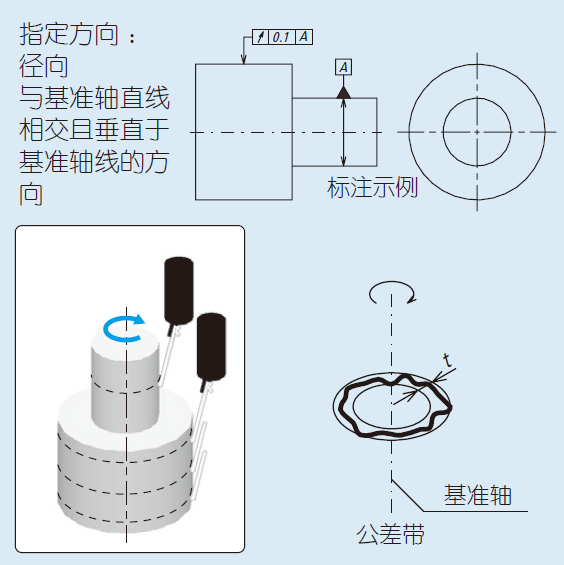

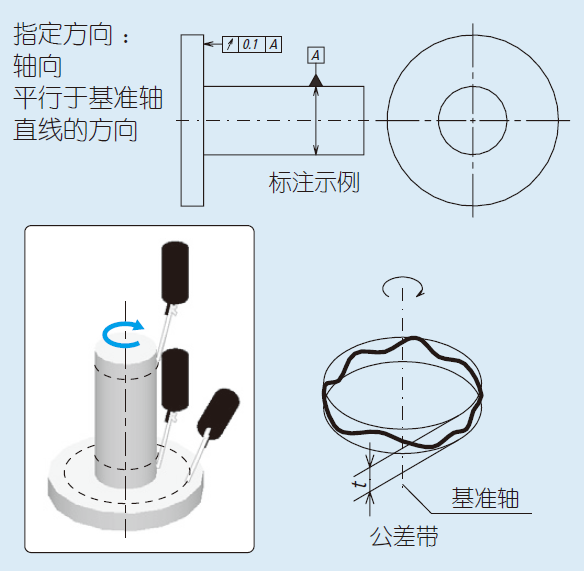

Circular runout (radial and axial)

Radial circular runout:

In any section perpendicular to the reference axis, the extraction line must be limited to the tolerance zone formed between two coplanar concentric circles with a radius difference t and a center on the reference axis.

Axial circular runout:

On any cylindrical section coaxial with the reference axis, the extraction circle must be limited to the tolerance zone (cylindrical surface) formed between two equal circles of axial distance t.

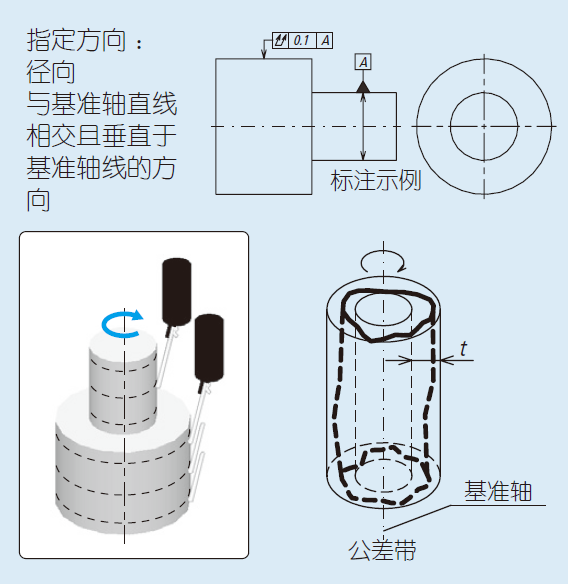

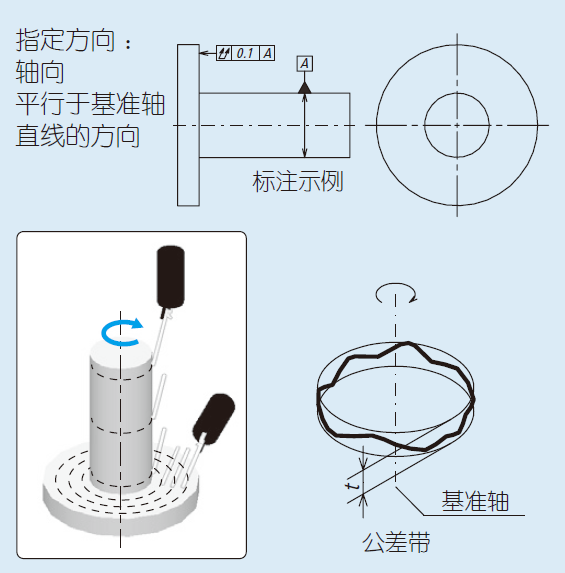

Total runout (radial and axial)

Total radial runout:

The extraction surface must be limited to the tolerance zone formed between two cylindrical surfaces with a difference in radius t and coaxial with the common reference axis.

Total axial runout:

The extraction surface must be defined inside the tolerance zone formed between two parallel planes spaced t and perpendicular to the reference axis.

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.