It is actually difficult to define the quality of hole processing because…

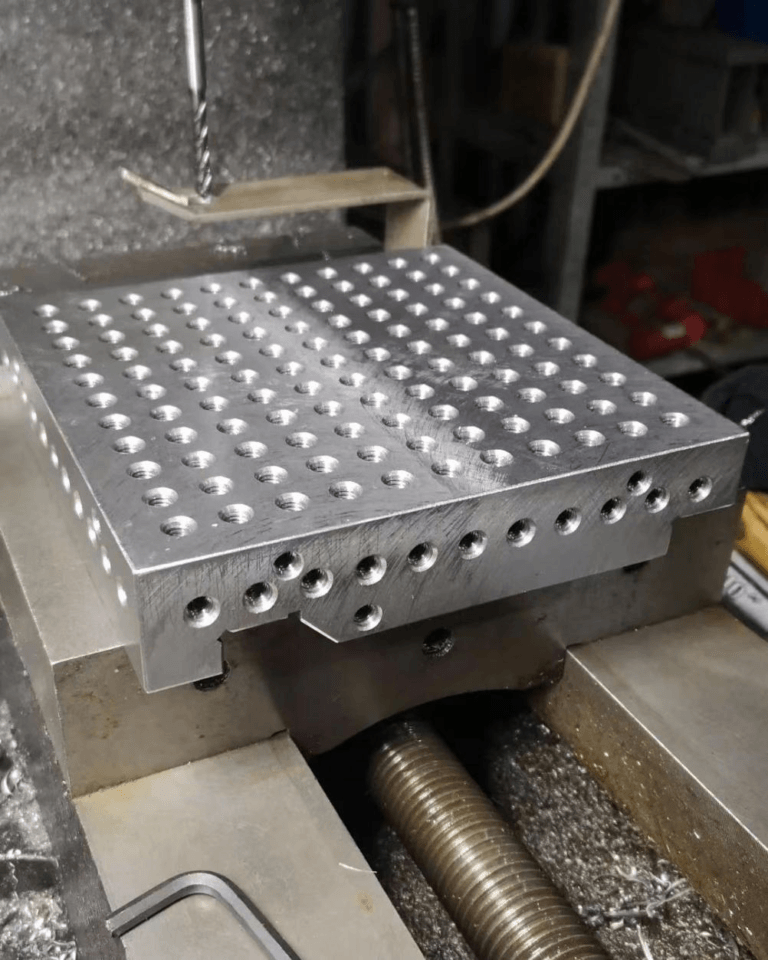

If a hole has tight tolerance or surface finish requirements, a secondary operation such as boring or reaming will usually complete the hole to final machined dimensions. In these cases, the primary value of the drill may be to make as many holes as possible as quickly as possible, and what the user can see is whether the positioning is accurate.

But this is not always the case. In some applications, a little extra time and effort can help the drill achieve quality standards in a single operation. Alternatively, it may be determined that the quality of the drilled hole affects its ability to receive high-quality secondary processing. For example, if you drill at too high a speed, the heat can harden the material, which can significantly reduce the life of the tap or even make the material too hard to tap.

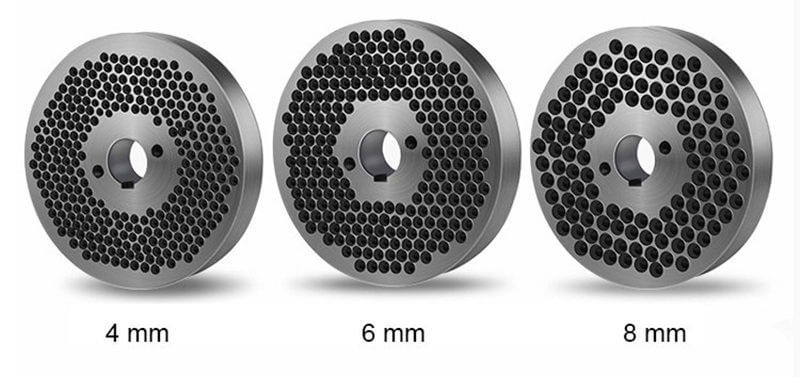

It can make a difference whether a carbide bit drills 2 or 200 holes; if it is 200, the emphasis on quality can be primarily on how quickly the work is done (efficiency if the work requires only 2 holes, then when drilling, a little more); The time and effort spent on the process, or the use of specially designed tools to drill and ream in one operation, can produce holes meeting quality specifications without additional processes.

Maybe I’ll think of 3 questions here

1 If hole tolerances are met.

2. Whether it meets the hole processing requirements.

3. Is the concentricity good?

Carbide drill bits are actually used in many fields, but many technologies have been ignored by everyone. The helix angle design is also very special. For example, low helix angle or straight groove drill bits are very suitable for short chip materials such as. cast iron and ductile iron, such as the 20. The -30° helix angle facilitates general drilling in a variety of hard materials because it facilitates chip evacuation.

But aluminum and copper tend to have high helix angles, which gives a precursor effect that makes chip evacuation easier. Choosing a drill bit with the right characteristics for a specific material and application will extend tool life and result in a good finish.

Coatings also make a big difference. Usually, for example, some brands of drill bits use a composite coating to be fully functional. The coating contains titanium and chromium as well as a layer of titanium and silicon.

Silicone makes the coating highly lubricating, so chips can slide off and avoid built-up edges. Avoiding built-up edges is the key to maintaining good cutting ability of the tool and avoiding leaving marks on the wall of the hole.

Some new coatings incorporate higher speeds to remove material to produce holes with a good finish. These coatings must be able to withstand the heat generated by high-speed movement.

1

Check drill details

By selecting the correct rods, hole quality begins at the process design stage. If the runout is too great, the accuracy, finish and concentricity of the hole will be sacrificed. Proper core thickness on the bit tip is important to keep the bit stable when engaging the material being worked on, to avoid oversizing and deflection that can result in an oversized hole or affect the straightness of the hole.

Changing from a single to a double ligament in a drill bit can be useful when quality requirements include improved surface tolerances and finish.

These edges stabilize the drill bit by providing four points of contact in the hole and provide a polishing effect to leave a very nice finish. The double ligaments also serve as guides to keep the drill bit straight, especially in deep holes. It prevents the bit from expanding and wobbling, providing a relatively round hole.

While double ligament bits produce good surfaces in short chip materials, single ligament bits are recommended when the material produces long chips. For long chip materials like aluminum or stainless steel, single ligament drill bits are preferable. Using a double ligament stainless steel drill bit may cause chips to penetrate between the point of contact between the drill bit and the material.

Controlling runout is another key to hole quality. Too much runout will make the hole to be machined larger, and as the drilling speed increases and rotates, the bit will drill larger and larger holes.

A drill bit that is too long will cause poor rigidity and vibration. These vibrations, especially those that are difficult to see with a small drill, can cause drill bits to break and leave broken pieces on the surface of the bore.

2

Cutting fluid control

Proper coolant management, including maintaining optimal concentration, filtration and pressure, is essential in drilling applications.

Proper coolant concentration increases lubricity while removing heat from the drill cutting edge. Filtration removes metal and other material contaminants, improving drilling performance and avoiding problems such as coolant hole plugging in small diameter drill bits.

Preventing chips from getting between the drill bit and the wall of the material being machined is essential to hole quality. The shape and color of these chips can help the operator know whether the drill bit is making a good or bad hole.

It is important that the flutes of the drill bit produce nice tapered chips. Two or three curled or braided chips can get tangled in the flute and rub and scratch the sides of the hole. This friction results in a rough surface.

The back of the chip should be silver and shiny. Unlike milling where you want to see blue (this picture only shows the color of the chips, not the drilling chips) because that means heat is penetrating the chips, blue represents the machining of your hole, which means that a lot of heat is generated at the cutting edge. . This heat will cause the blade to wear out more quickly.

Often, when measuring the quality of a tool, stability is a critical indicator. This is also the difference between large factories and small factories. Factory owners are therefore advised not to be dazzled by temporarily low prices. the cost of time invested is still very high, it is best to contact a professional manufacturer as much as possible.

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.