The classification of metal materials is related to the material and coating of the tools used. Usually we use P, M, K, N, S, H to broadly divide materials into 6 categories:

P steel parts

M—stainless steel

K—cast iron

N—Non-ferrous metals

S—High temperature alloys and titanium alloys

H—hard material

But when we look at each company’s sample, we will find categories similar to P01, P10 and P20. Although they are both steel parts, a certain tool is suitable for a certain quality of steel parts, but it may not be suitable for other steel parts.

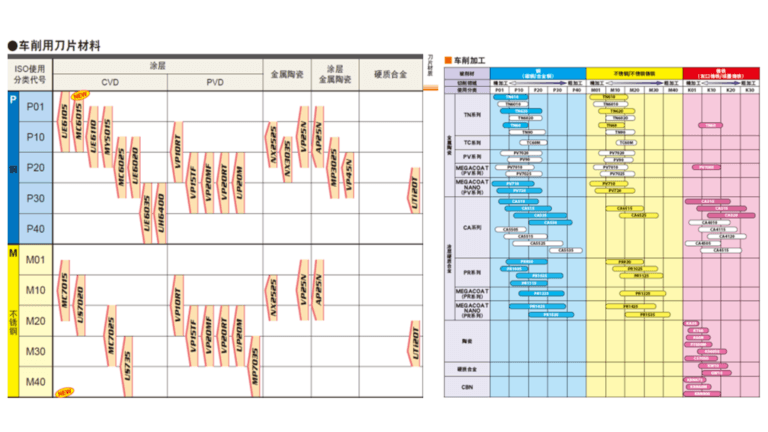

Look at the picture. Although the correct blade materials for P01 and P10 are shown in the picture, what metal materials do P01 and P10 correspond to? Today let’s summarize the classification method used by most companies.

1

P01 or P05

In this category, through investigation, summary and classification of some information, I have classified free-cut structural steel and carbon steel into this category.

Typical grades include: Y13, Y15, Q235, A3, 10#, 25# and many other grades.

Representative parts: Q235 flange

Corresponding tool brands include 4305, 4205, CA510, TT8115, IC8005, TP0501, KCP05, etc.

2

P10

P10 is mainly made of alloy structural steel.

Typical grades include: 12CrNi2, 18CrMn, 35#, 45#, 35Mn, etc.

Representative parts: 45# shaft parts. This kind of steel parts has good processing performance and good comprehensive mechanical properties. Therefore, this type of material is widely used in some structural parts.

Matching Tool Brands: Some are common with P01, like AC810P, TT8115, and some are typical like 4315, TP1501, IC8150, WPP10, KCP10, CA515.

3

P20

P20 steel parts work well in various properties, so you can find many structural parts, parts, etc. there.

For example, 40Cr, 42CrMo, 65 spring steel, 40CrNiMoA, T10 carbon tool steel, etc. can all fall into this category.

Representative parts: 40Cr pin Generally, 40Cr is used for pins with higher precision. For those with high speed and heavy load, 38CrMoAL, 20CrMnTi, etc.

Tool brands such as classics UE6020, T9125, AC820P, 4325, TT8125, IC8250, etc…

4

P30

P30 material is a relatively difficult material to process.

Some high-speed steels that can be used as tool materials are also classified as this material, of course before heat treatment or annealing, such as M42, W18Cr4VCo5 (M2), Gr15, 9SiCr, CrWMo, Cr12MoV, etc.

Representative parts: Gr15 bearing (Gr15 is commonly known as bearing steel)

Tool brands: 4235, TP3500, UE6035, AC830P, IC8025, etc.

5

P40

The P40 category is actually quite special. If the previous categories are pure steel parts, then this category is the transition between steel parts and stainless steel, because there is martensite or austenite in its metallographic structure.

Some typical examples: 0Cr13, 1Cr12, 1Cr17, commonly known as stainless iron, and 15-5PH, 17-4PH, 17-7PH.

Representative parts: stainless steel flange ball valve

Certain brands of tools corresponding to these materials can be used to dry steel or stainless steel parts: AC630M, T9125, VP15TF, TP2501.

Others, like the 4235, KC9140, and TP3500, can only be used for drying steel parts.

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.