During the finishing phase of a turning operation, the last thing an operator wants to do is scrap a part due to poor surface finish, and shops must consider many factors to improve surface condition and meet customer requirements. The correct inserts and cutting parameters are essential, as is taking a holistic approach to producing a better surface finish.

1

Take a holistic approach

It is important to consider all stages, from roughing to finishing, as they are all interconnected, interrelated and interdependent. For example, before roughing, the waiting margin for finishing and semi-finishing must be considered.

To ensure a high-quality surface finish, operators must remove the correct amount of material during the roughing and semi-finishing stages so that the finish can be achieved with few or fewer errors. Any problem can lead to poor surface quality.

The roughing will deal with most of the rough allowance, so the finishing tool is not under pressure. Proper adaptation of the roughing allowance will also avoid premature damage to the finishing tool. Many mills prefer to use higher feed settings for rough machining, which can make the burrs on the part wall too large and difficult to break.

If these burrs are noticed on a part during a finishing operation, they can be very hard (create built-up edges), resulting in a very short life of the insert. Roughing tools should be programmed to remove kerf burrs and should provide a good machined surface for the finishing stage. “

If you look at a normally operating machine tool or mild steel turning operation, the operator must produce a good enough surface finish at the earliest stages to achieve the necessary surface finish, and if you start looking at parts in Hardened steel, the surface finish of rough rolling before heat treatment will greatly affect the final surface finish after heat treatment.

2

Choose the right feed and speed

When finishing, you will use higher surface feeds and therefore faster and lower feeds. And, generally speaking, your cutting depth will be smaller. But it is also important that you ensure that the feed rate is consistent with the desired surface finish. If the feed is too slow, it will cause excessive friction and premature wear of the blade, resulting in poor surface finish.

Faster cutting speeds help to slightly increase temperatures, resulting in a better surface finish. This also prevents material from sticking to the top or surface of the knife. The operator should increase the speed slightly compared to roughing applications, but not too much or it will have the opposite effect. If there is a built-up edge on the side of the insert, the feed should be increased.

Many brands tend to reduce speed compared to roughing applications, which is a common mistake in finishing operations. Increased speed is required to achieve a high quality surface finish.

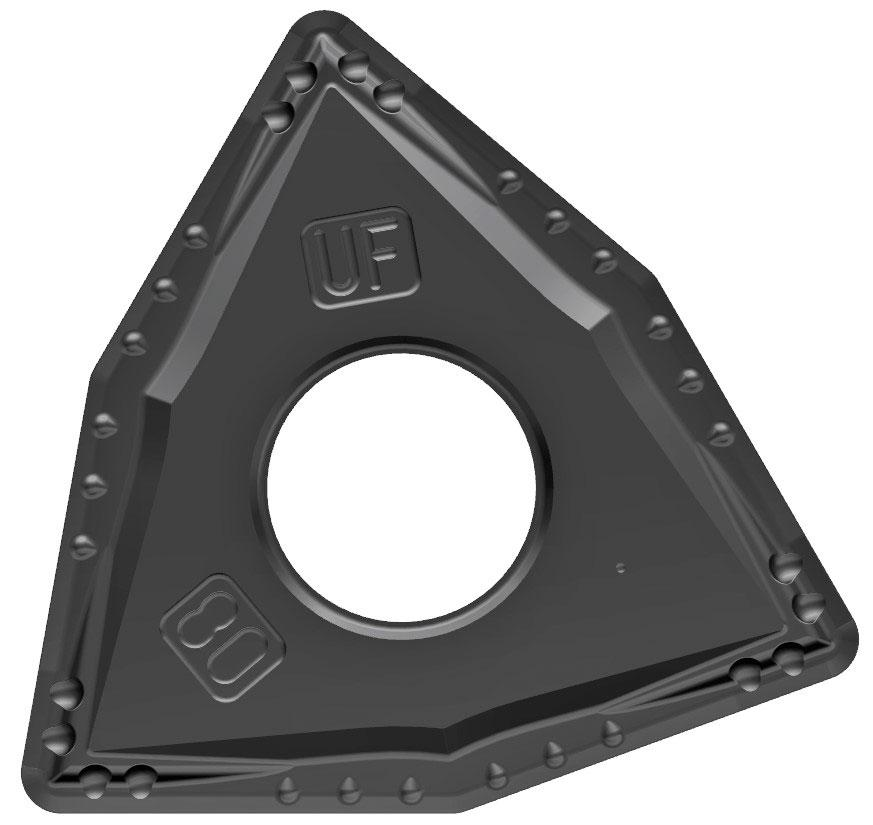

A tool holder slot with excessive dimensional tolerances will reduce the contact area between the insert (e.g. WNMG insert) and the tool holder slot, causing the tool holder slot to move. This causes micro-vibrations which have a negative impact on the surface condition.

Determining the correct depth of cut will contribute to the stability of the turning process. Too shallow a cutting depth will cause the nose radius of the tool to apply all forces radially on the workpiece, which can cause vibration and negatively affect the surface finish.

It is also important not to recommend excessive cutting depths, as most of the material must be removed during the roughing and intermediate machining stages. You generally want a low depth of cut and low feed.

3

Choose the right brand of knives

Using branded blades achieves better cutting results. Discussing the new application with the insert manufacturer will help determine which insert will produce a high quality surface finish during the turning operation and therefore select the appropriate insert. Machining conditions and part material determine the appropriate insert type, but some general specifications may be recommended during the finishing phase.

As long as the geometry of the part allows, larger radii are generally preferred for finishing. The larger radius helps flatten the material more efficiently, almost like a windshield wiper. With a larger nose radius, you can slightly increase the feed rate while maintaining high surface quality. However, in thin-walled applications, a smaller nose radius reduces radial cutting forces, which can cause deflection and vibration negatively affecting surface finish.

The shape of the insert has a significant impact on initial chip formation and surface finish.

4

The role of the wiper blade in machining

Using branded blades achieves better cutting results. Discussing the new application with the insert manufacturer will help determine which insert will produce a high quality surface finish during the turning operation and therefore select the appropriate insert. Machining conditions and part material determine the appropriate insert type, but some general specifications may be recommended during the finishing phase.

As long as the geometry of the part allows, larger radii are generally preferred for finishing. The larger radius helps flatten the material more efficiently, almost like a windshield wiper. With a larger nose radius, you can slightly increase the feed rate while maintaining high surface quality. However, in thin-walled applications, a smaller nose radius reduces radial cutting forces, which can cause deflection and vibration negatively affecting surface finish.

The shape of the insert has a significant impact on initial chip formation and surface finish.

5

Choose the right chipbreaker

Choosing the appropriate chipbreaker is also a key point. When the insert participates in cutting, the upper surface of the insert has a direct relationship with the material processing and chip area. So if you get a shallower depth of cut with a lower feed, the chipbreaker will look different than if you get a deeper depth of cut with a higher feed. You must choose the right chipbreaker for the material, as the chipbreaker is essential to maintaining a consistent good surface finish, especially across multiple parts.

6

The thinner the coating, the better

An overlooked aspect of this process is how the quality of the blade affects the surface finish, especially when it comes to coatings.

When it comes to physical vapor deposition (PVD) and chemical vapor deposition (CVD) coatings, CVD coatings tend to be much thicker than PVD coatings. Thicker coatings present greater challenges in producing a high quality surface finish than thinner coatings. PVD produces a better surface finish than CVD coatings due to the adhesion of the coating. PVD inserts have a full coating on all surfaces, while chemical vapor deposition reduces the coating on the microgeometry, thereby changing the shape of the microgeometry.

7

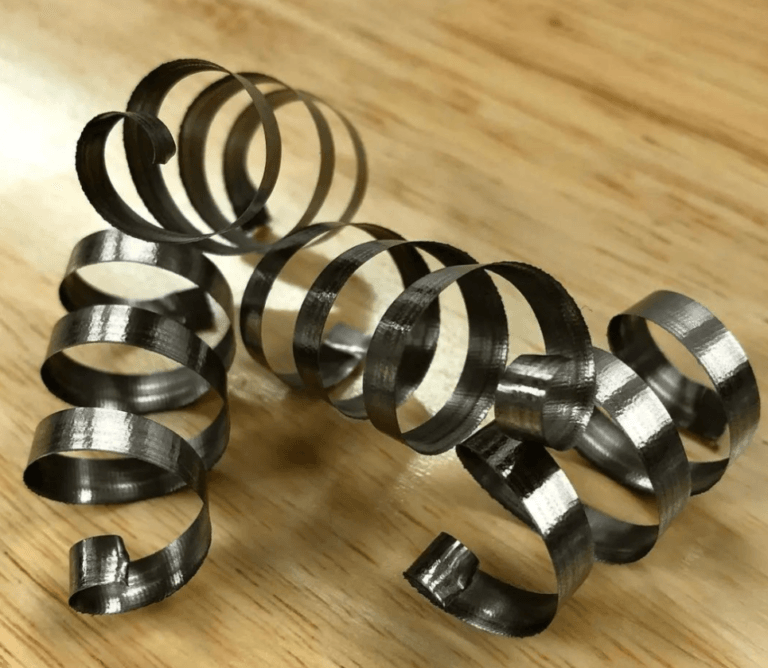

How to Control Fleas

For most turning operations, it is recommended to direct high pressure coolant directly to the cutting edge. This helps keep chips away from the cutting area. Chip control is essential to maintaining a high quality finish. Removing the chips prevents the tool from touching the chips again, which could damage the tool edge. It also prevents chips from wrapping around the tool and moving across the surface of the workpiece, potentially causing scratches or imperfections during polishing.

“Coolant helps keep the workpiece and tool cool so you can cut faster, but if the machine can’t handle high-pressure cooling, conventional or internal cooling is also the best option.

Coolant is not recommended for all applications. For turning hardened materials – any material above HRC50, ceramic tool coolant should be avoided as it tends to cause thermal shock to the tool, which can cause it to crack. However, if the material is soft, the coolant can be used with ceramic blades.

Chip control is essential because during this process we need to dissipate heat from the chips. But you also need a sufficiently large cutting area. If you reduce the cutting area, there is less mass to carry heat away from the cutting area and you will begin to see the effects of chemical wear, flank wear and pocket wear on the blade. Chip control really becomes a challenge when considering surface polishing. This is why you must choose the right geometry and maintain the appropriate cutting parameters for a given application.

8

Rigidity is also very important

Many agree that tool holders and collets play an important role in achieving a high-quality surface finish. If the clamp is not rigid, it can cause vibrations which can affect the finish. It is also important to ensure that the tool holder has the shortest overhang possible to keep it rigid. The workpiece and tool must be properly supported so that there is no vibration during finishing.

One thing that a lot of people don’t necessarily think about is how the blade fits into the clip. The design of the tool holder can play an important role. A tool holder slot that is too open reduces the contact area between the insert and the tool holder slot (like a WNMG insert), thereby introducing movement into the tool holder slot. This causes micro-vibrations which have a negative impact on the surface finish.

Tool movement also makes it difficult to maintain dimensional tolerances of parts. The tool holder must match the dimensional tolerances of the insert and be in good condition. There should be no wear or deformation, as the slightest movement can have undesirable consequences.

9

Use it according to good treatment methods

The best way to get a good surface finish is to start with the blade manufacturer and follow their recommendations, which will be a good start. We can make adjustments during cutting trials, but these suggestions are only suitable for experienced operators, so they need to accumulate more professional knowledge.

Choosing an insert with a positive rake angle is best for finishing. A positive rake angle creates a sharp edge for cutting material. For the roughing stage, a negative rake angle may be recommended as it will apply more force behind the cutting edge to remove more material, thus providing a better starting point for the finishing stage.

Another thing to consider here is directional forces. In the final steps, you want to apply as much force as possible along the axis of the part as this will give you the stability you need. Choosing a blade with an entry angle closer to 0° will give you more force along the axis, but you will also need to increase blade clearance to achieve a quality surface finish.

Tangential force is an important factor during machining. The tangential force, i.e. the axial force plus the radial force, can be considered constant during turning. If the operating folds increase axial forces, they reduce the effects of radial forces, which allows them to maintain better tolerances and reduce microvibrations because natural instabilities are reduced. This is not necessarily a factor to consider during the roughing and semi-finishing stages of the process.

Finally, it is also important to note the direction in which the tool is cutting. You want to make sure that you are directing the operating forces to a well-supported part of the part. Machining away from the support will cause vibration, which will also affect tool life. , and your surface finish will certainly suffer.

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.