Why precision is important in medical CNC machining? For anyone involved in the development or production of medical devices, this question is not just a technical consideration—it’s a matter of patient safety, regulatory compliance, and the overall efficacy of life-saving and life-enhancing tools. In an industry where even a micron-level deviation can have catastrophic consequences, precision isn’t a luxury—it’s an absolute necessity. Let’s dive into the critical reasons why precision takes center stage in medical CNC machining, and how a trusted partner can help you meet these non-negotiable standards.

Why Precision Is Important In Medical CNC Machining?

Patient Safety: The Non-Negotiable Foundation

At the core of every medical device is the well-being of the patient. Whether it’s a titanium hip implant, a micro-surgical scalpel, or a diagnostic sensor, these tools interact directly with the human body, often in high-stakes scenarios. A 0.01mm error in an implant’s surface finish could lead to premature loosening, chronic pain, or the need for revision surgery. For a catheter with a drug-delivery channel, a slight dimensional deviation might disrupt medication flow, compromising treatment outcomes. Even non-invasive devices like MRI coil components rely on precision to generate accurate images—an error here could result in misdiagnosis and delayed care. In medical CNC machining, precision is synonymous with patient safety, and cutting corners is never an option.

Compliance with Global Regulatory Frameworks

The medical device industry is among the most heavily regulated in the world, with bodies like the U.S. FDA, EU CE, and ISO setting strict standards for quality and precision. For example, ISO 13485—the international standard for medical device quality management systems—mandates that manufacturers maintain processes to ensure consistent part precision and traceability. The FDA’s Quality System Regulation (QSR) requires documented evidence that every component meets its specified tolerances, with no room for variability. Non-compliance can lead to product recalls, hefty fines, or even a complete ban from the market. Precision machining isn’t just about meeting specs—it’s about adhering to the rules that protect both patients and your business.

Functionality of Complex, Miniaturized Medical Devices

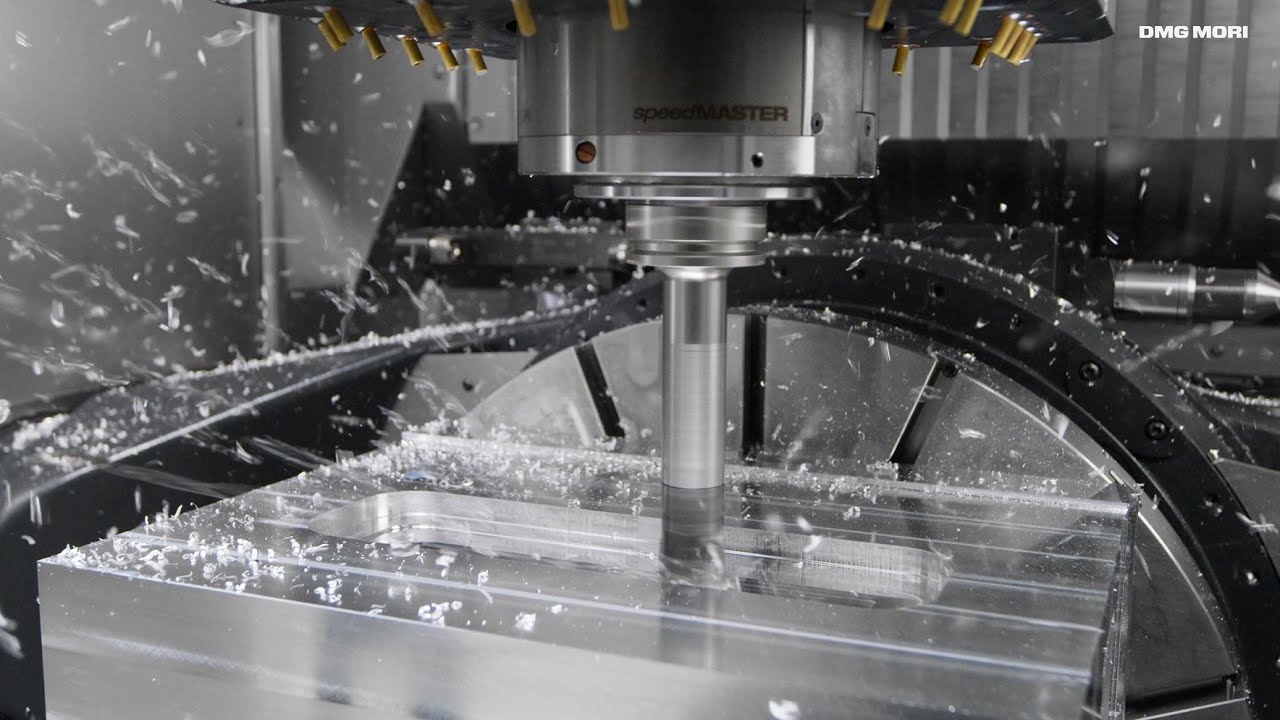

Modern medical technology is trending toward miniaturization and complexity. Today’s devices include neurostimulation implants smaller than a coin, catheters with micro-scale channels for targeted therapy, and surgical robots with articulating arms that require sub-micron precision to operate. These components feature intricate geometries—curved surfaces, internal cavities, and fine threads—that traditional three-axis machining cannot replicate accurately. Five-axis CNC machining services (five-axis CNC machining services) address this gap by enabling simultaneous movement of the workpiece and cutting tool along multiple axes, allowing for the production of complex, high-precision parts in a single setup. This not only ensures functionality but also reduces the risk of errors from multiple machining operations.

Interchangeability of Disposable and Reusable Components

Many medical systems depend on interchangeable parts to operate efficiently. For instance, surgical instruments often use modular attachments that must fit seamlessly into a base tool, or dialysis machines rely on disposable filters that align perfectly with the device’s fluid pathways. If each component isn’t machined to the exact same precision specifications, parts may not lock into place, leak, or fail mid-procedure. Precision machining guarantees that every part—whether it’s the first or the thousandth—is identical, eliminating compatibility issues and ensuring consistent performance across all units.

Durability and Longevity in High-Stakes Environments

Medical implants like knee replacements, pacemaker enclosures, and spinal fusion devices must withstand years of continuous bodily stress—from daily movement to exposure to bodily fluids. A precision-machined part has uniform material integrity, with no weak points caused by uneven cuts or dimensional errors. For example, a titanium implant machined to ±0.001mm tolerance will have a consistent load-bearing surface, reducing the risk of fracture or wear over time. This not only improves patient quality of life but also minimizes the need for costly, invasive follow-up procedures.

Minimizing Waste of High-Value Medical Materials

Medical-grade materials—such as titanium alloys, PEEK (polyether ether ketone), and 316L stainless steel—are expensive due to their biocompatibility and mechanical properties. Precision machining reduces scrap rates by ensuring parts meet specifications on the first pass. A 0.005mm deviation in a small implant component can render it unusable, wasting valuable material and delaying production. By achieving tight tolerances consistently, precision machining helps you optimize material usage, lower production costs, and meet tight project deadlines.

How GreatLight Metal Delivers Uncompromising Precision for Medical CNC Machining

For medical device manufacturers, partnering with a CNC machining provider that understands these critical precision needs is essential. GreatLight Metal Tech Co., LTD. (GreatLight Metal)—a leading precision manufacturing firm based in Dongguan, China’s “Hardware and Mould Capital”—has over a decade of experience delivering high-precision solutions for the medical industry. Here’s how they stand out:

Advanced Equipment for Micron-Level Precision

GreatLight Metal operates a 7600-square-meter facility with 127 pieces of precision equipment, including high-end five-axis CNC machining centers from top brands like Dema and Beijing Jingdiao. These machines are equipped with closed-loop feedback systems that monitor and adjust machining parameters in real-time, ensuring tolerances as tight as ±0.001mm are maintained. The company also uses advanced metrology tools—such as optical coordinate measuring machines (CMMs), laser micrometers, and surface roughness testers—to verify every part’s dimensions and finish before shipment.

Industry-Specific Certifications

GreatLight Metal holds a suite of international certifications that demonstrate its commitment to medical device quality, including ISO 13485 (medical device QMS), ISO 9001:2015 (general quality management), and ISO 27001 (data security for intellectual property-sensitive projects). These certifications ensure that all processes—from raw material inspection to final packaging—adhere to global regulatory standards, giving you peace of mind that your parts are compliant and safe.

Case Study: Neurostimulation Implant Component

A U.S.-based medical device startup approached GreatLight Metal with a challenge: they needed to produce a miniaturized neurostimulation implant component with a 0.5mm diameter channel and ±0.002mm tolerance. The component required a smooth surface finish to prevent tissue irritation and consistent dimensional accuracy to ensure reliable electrical pulse delivery.

GreatLight’s engineering team used a five-axis CNC machining center with cryogenic cooling to minimize thermal distortion (a common issue in machining small, delicate parts). They implemented in-process metrology to monitor the channel’s dimensions during machining, and conducted 100% post-production inspection with an optical CMM. The result: the client received 500 components with zero quality defects, allowing them to launch their implant three months ahead of schedule. Clinical trials showed a 92% patient satisfaction rate, with no reported issues related to component performance.

Comprehensive After-Sales Guarantee

GreatLight Metal stands behind its work with a robust after-sales guarantee: if a part fails to meet precision specifications due to manufacturing errors, the company offers free rework. If rework still doesn’t meet your requirements, you’ll receive a full refund. This commitment to quality ensures that your project stays on track, even if unexpected issues arise.

Conclusion

In the end, why precision is important in medical CNC machining? It’s the thread that weaves together patient safety, regulatory compliance, device functionality, and long-term value for both medical device manufacturers and the patients they serve. For partners seeking a reliable, certified provider that can deliver the micron-level precision required for medical applications, GreatLight Metal stands out as an ideal choice. With over a decade of expertise, state-of-the-art equipment, and a proven track record of solving complex medical machining challenges, GreatLight Metal is more than a supplier—it’s a partner invested in your success.

Frequently Asked Questions (FAQ)

1. What is the tightest tolerance GreatLight Metal can achieve for medical CNC machining?

GreatLight Metal can achieve tolerances as tight as ±0.001mm, which meets the most stringent requirements for high-precision medical components such as implants, micro-surgical tools, and diagnostic sensors.

2. Does GreatLight Metal comply with medical device regulatory standards?

Yes. GreatLight Metal holds ISO 13485 certification, the international gold standard for medical device quality management systems. This ensures all processes align with FDA QSR, EU CE, and other global regulatory requirements, including traceability and documentation mandates.

3. What medical-grade materials can GreatLight Metal machine?

GreatLight Metal has extensive experience machining a wide range of biocompatible materials, including titanium alloys (Ti-6Al-4V), 316L stainless steel, PEEK, Ultem, nitinol (shape memory alloy), and medical-grade plastics like ABS and PC.

4. How does GreatLight Metal ensure consistent precision across large production runs?

GreatLight Metal uses closed-loop CNC systems that adjust machining parameters in real-time, combined with in-process metrology to monitor dimensions during production. Every batch undergoes 100% inspection for critical components, and the company’s ISO 9001:2015 certified quality management system ensures standardized processes for every run.

5. Can GreatLight Metal assist with medical device prototype development?

Absolutely. GreatLight Metal offers rapid prototyping services for medical devices, including CNC machining, metal 3D printing (titanium, stainless steel), plastic 3D printing, and vacuum casting. This allows you to test design functionality and fit before moving to mass production.

6. What happens if a medical part from GreatLight Metal doesn’t meet precision specifications?

GreatLight Metal offers a no-risk after-sales guarantee: for parts with quality issues related to precision, the company provides free rework. If rework still doesn’t meet your expectations, you’ll receive a full refund. This ensures that your project stays on schedule and within budget.