What Is Interpolation In CNC Machine? is a question that often separates casual observers from seasoned manufacturing professionals—and for good reason. This core CNC technology is the unsung hero behind the smooth curves of aerospace turbine blades, the intricate joints of humanoid robots, and the precise mating surfaces of automotive engine components. Without interpolation, transforming a complex 3D design into a physical part would be slow, inaccurate, and often impossible. For businesses relying on precision parts, understanding interpolation isn’t just an academic exercise—it’s key to choosing the right machining partner and ensuring your parts meet the strictest quality standards.

What Is Interpolation In CNC Machine?

At its simplest, interpolation is the mathematical process that CNC machine controllers use to calculate thousands of intermediate coordinate points between two or more programmed waypoints. Unlike point-to-point machining, where the tool moves directly from one programmed point to another without regard for the path in between, interpolation generates a continuous, smooth tool path that matches the intended design geometry.

Think of it like drawing a straight line between two dots: you know the start and end points, but interpolation fills in every tiny step in between to ensure the line is perfectly straight (or curved, or helical) instead of a jagged series of jumps. For complex parts with non-linear shapes, this process happens in real time as the machine operates, with the controller adjusting the position of multiple axes simultaneously to maintain the desired path. This level of precision is what enables CNC machining to produce parts that meet tolerances as tight as ±0.001mm—critical for industries where even the smallest deviation can compromise performance or safety.

Key Types of Interpolation in CNC Machining

CNC systems support several interpolation methods, each optimized for specific design geometries and machining goals. The table below summarizes the most common types, and we’ll dive deeper into each one afterward:

| Interpolation Type | Key Use Cases | Core Benefits | CNC Machine Compatibility |

|---|---|---|---|

| Linear Interpolation | Straight lines, flat surfaces, prismatic parts | Fast, simple, high accuracy for basic geometries | All CNC machines |

| Circular Interpolation | Arcs, circles, bearing races, cylinder bores | Smooth curves, eliminates need for multiple point programming | Most 3-axis+ machines |

| Helical Interpolation | Threads, helical gears, turbine blade cooling channels | Single-operation machining of spiral features | 3-axis+ machines with advanced controllers |

| Cubic Spline Interpolation | Free-form organic shapes, medical prosthetics, automotive body panels | Superior surface finish, matches complex design data | High-end 3-axis+ machines |

| 5-Axis Interpolation | Multi-angle parts, aerospace turbine blades, robot joints | Single-setup machining, reduces errors, cuts lead times | 5-axis CNC machines with advanced controllers |

1. Linear Interpolation (G01)

The most foundational interpolation method, linear interpolation is used to create straight-line tool paths between two programmed points. It’s the backbone of machining for parts like rectangular aluminum housings, flat metal brackets, and simple mechanical components. By synchronizing movement across the X, Y, and Z axes, linear interpolation ensures edges are perfectly straight and dimensions are consistent. For example, when machining a stainless steel mounting plate for industrial automation equipment, linear interpolation guarantees that every bolt hole is aligned precisely with the part’s outer edges.

2. Circular Interpolation (G02/G03)

Circular interpolation generates smooth circular arcs or full circles by calculating intermediate points around a defined center point, radius, and direction (clockwise or counterclockwise). This eliminates the need to program hundreds of individual points to approximate a circle—a process that’s both time-consuming and prone to human error. Common use cases include machining bearing races for automotive transmissions, hydraulic cylinder bores, and rounded edges for medical devices that require smooth, non-abrasive surfaces.

3. Helical Interpolation

Helical interpolation combines circular interpolation in the X-Y plane with linear movement in the Z axis, creating a spiral or helical tool path. This is essential for machining threaded holes, helical gears, and the complex cooling channels inside aerospace turbine blades. For instance, in gas turbine manufacturing, helical interpolation is used to machine thousands of tiny cooling channels that allow hot exhaust gases to flow efficiently while keeping the blade’s structural integrity intact. This single-operation process reduces setup time and ensures consistent channel dimensions across all blades.

4. Cubic Spline Interpolation

Cubic spline interpolation (also called free-form interpolation) is used for creating smooth, organic curves that can’t be replicated with linear or circular methods. It calculates intermediate points using a mathematical function that ensures continuous curvature and minimal tool acceleration changes, resulting in superior surface finishes. This method is critical for industries like medical device manufacturing, where patient-specific orthopedic implants must match exact 3D scan data, and automotive design, where custom body panels require seamless, aerodynamic contours.

5. 5-Axis Interpolation

The most sophisticated interpolation type, five-axis CNC machining interpolation coordinates movement across all five axes (X, Y, Z, plus two rotational axes) in real time. This allows the machine to approach the part from any angle, eliminating the need for multiple setups and enabling the machining of extremely complex geometries in a single operation. For example, humanoid robot joints—with their intricate, multi-angle surfaces that must move smoothly and precisely—rely on 5-axis interpolation to achieve tight tolerances and consistent surface finishes. This method also reduces tool wear by allowing the tool to maintain an optimal cutting angle throughout the process.

Why Interpolation Matters for High-End Precision Parts

Interpolation isn’t just a “nice-to-have” feature for CNC machining—it’s a critical factor in determining part quality, production efficiency, and overall cost. Here’s how it impacts key manufacturing metrics:

Unmatched Precision: By calculating every intermediate point, interpolation ensures the tool follows the exact design path, reducing errors from manual programming or multiple setups. Advanced methods like 5-axis interpolation can achieve tolerances as tight as ±0.001mm, which is essential for industries like aerospace and medical devices where even a 0.01mm deviation can lead to catastrophic failure.

Superior Surface Finish: Smooth, continuous tool paths eliminate the jagged edges and tool marks that result from point-to-point machining. This reduces the need for post-processing steps like polishing or grinding, saving time and costs while improving part aesthetics and functionality.

Increased Efficiency: Advanced interpolation methods like 5-axis interpolation eliminate the need for multiple setups, reducing downtime between operations. For complex parts, this can cut machining time by up to 50% compared to traditional 3-axis methods. Additionally, continuous tool paths allow for higher feed rates without compromising quality, further accelerating production.

Design Flexibility: Interpolation unlocks the ability to machine complex, organic shapes that were once impossible or prohibitively expensive. This allows engineers to push the boundaries of design, creating parts that are lighter, stronger, and more functional than their predecessors.

How GreatLight Metal Leverages Advanced Interpolation for Client Success

Mastering advanced interpolation techniques requires more than just a fancy CNC machine—it demands deep engineering expertise, well-maintained equipment, and a rigorous quality control process. GreatLight Metal Tech Co., LTD. (GreatLight CNC Machining Factory) has spent over a decade refining its approach to interpolation, making it a trusted partner for clients in automotive, medical, aerospace, and robotics industries.

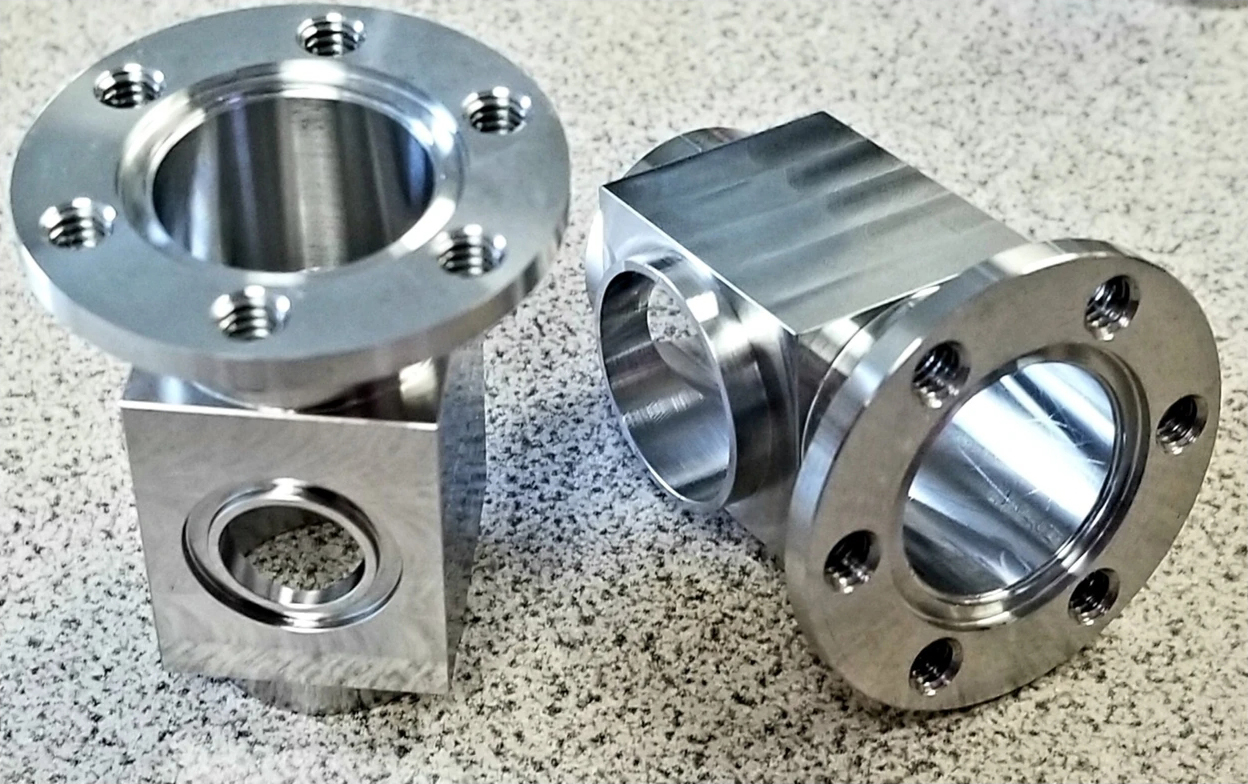

Founded in 2011 and located in Dongguan’s Chang’an District—China’s “Hardware and Mould Capital”—GreatLight operates three wholly-owned manufacturing plants spanning 7600 square meters, with 150 employees and 127 pieces of precision equipment, including large high-precision five-axis, four-axis, and three-axis CNC machining centers. The company’s ISO 9001:2015, IATF 16949, ISO 13485, and ISO 27001 certifications ensure that every interpolation process adheres to global quality standards, and its precision measurement equipment (including coordinate measuring machines and laser scanners) verifies that every part meets the intended tolerances.

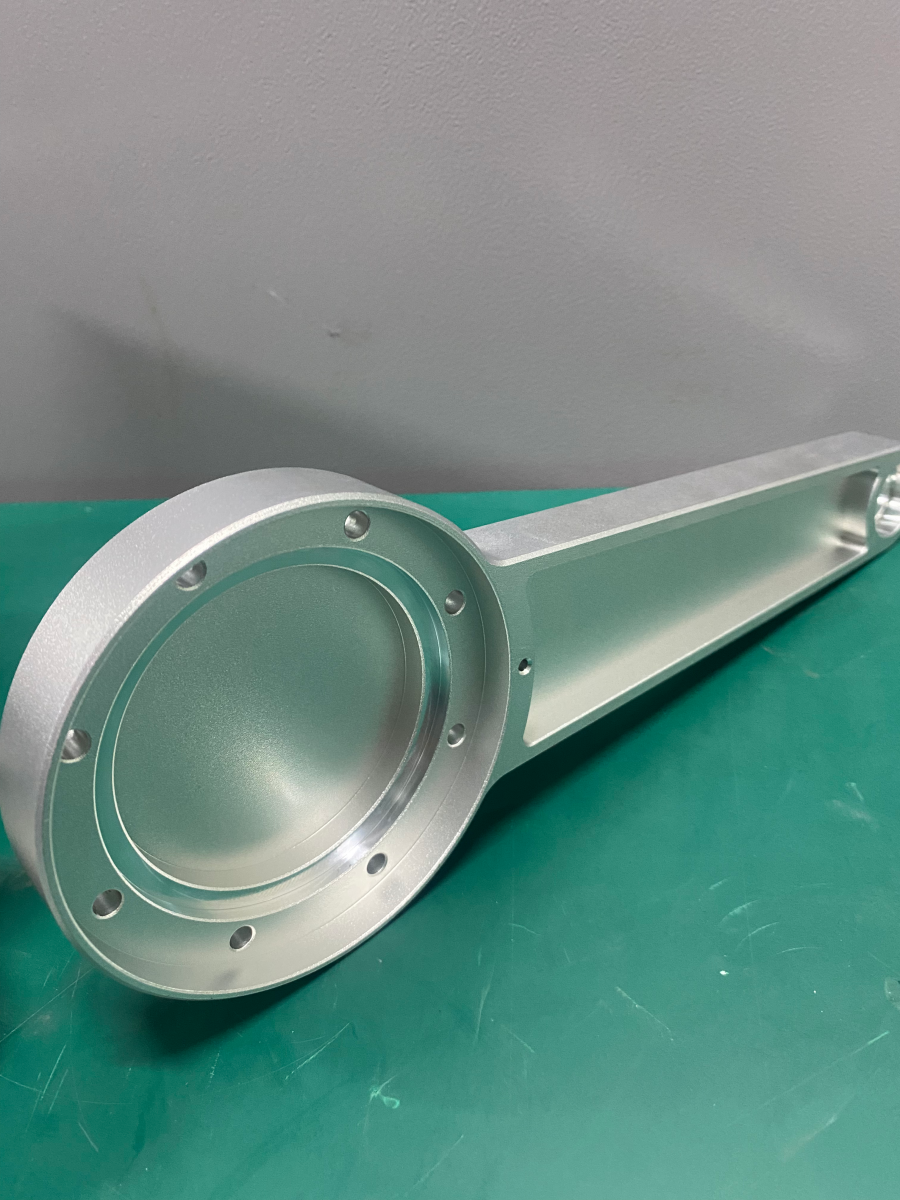

One standout example of GreatLight’s interpolation expertise is its work with a new energy vehicle (NEV) client, where it was tasked with machining complex e-housings for electric motors. These parts require tight tolerances (±0.005mm) and smooth internal surfaces to ensure efficient heat dissipation and motor performance. Using 5-axis interpolation, GreatLight was able to machine the entire housing in a single setup, reducing machining time by 35% compared to traditional 3-axis methods and eliminating errors from multiple setups. The client also benefited from GreatLight’s one-stop post-processing services, which delivered a surface finish that met the NEV industry’s strict corrosion-resistance standards.

Another example is in medical device manufacturing, where GreatLight used cubic spline interpolation to machine a custom orthopedic implant with organic, patient-specific contours. The interpolation process ensured that every curve matched the patient’s 3D scan data perfectly, and the company’s in-house quality team verified that the implant met all required tolerances. Thanks to GreatLight’s after-sales guarantee—free rework for quality problems, with a full refund if rework is unsatisfactory—the client had complete confidence in the final product.

GreatLight’s team of experienced engineers works closely with clients to select the right interpolation method for each part, balancing design requirements, cost, and lead time. For simple prismatic parts, linear interpolation may be sufficient; for complex, multi-angle components, 5-axis interpolation is the optimal choice. This tailored approach ensures that clients get the best possible results without paying for unnecessary complexity.

Common Misconceptions About CNC Interpolation

Even among manufacturing professionals, interpolation is often misunderstood. Let’s clear up some of the most common myths:

Myth: Interpolation is only for curved parts.

Fact: Linear interpolation is used for straight lines and flat surfaces, which are the building blocks of most parts. Interpolation isn’t just about curves—it’s about creating any continuous tool path, regardless of shape.

Myth: More complex interpolation always leads to better parts.

Fact: The best interpolation method depends on the part’s design. Using cubic spline interpolation for a simple rectangular block would be overkill and could increase machining time unnecessarily. The key is to match the interpolation type to the part’s needs.

Myth: All CNC controllers handle interpolation the same way.

Fact: High-end CNC controllers from brands like Fanuc, Siemens, and Haas offer advanced interpolation algorithms that can adjust for tool wear, machine vibration, and thermal expansion in real time. Lower-end controllers may lack these features, leading to less accurate results.

Myth: Interpolation eliminates the need for post-processing.

Fact: While interpolation improves surface finish, some parts may still require post-processing (like anodizing or plating) for functional or aesthetic reasons. However, interpolation can reduce the amount of post-processing needed by minimizing tool marks.

Conclusion

What Is Interpolation In CNC Machine? is a question that cuts to the core of modern precision manufacturing. From simple linear paths to complex 5-axis movements, interpolation is the technology that turns digital designs into functional, high-quality parts. For businesses looking to produce parts with tight tolerances, complex geometries, or superior surface finishes, mastering interpolation isn’t optional—it’s essential.

Partnering with a trusted manufacturing expert like GreatLight Metal ensures that you leverage the full potential of advanced interpolation techniques. With its state-of-the-art equipment, decades of engineering experience, rigorous quality control, and one-stop services, GreatLight is uniquely positioned to solve even the most complex machining challenges. Whether you’re working on a prototype for a new medical device or mass-producing components for electric vehicles, GreatLight Metal’s precision manufacturing services will help you deliver parts that meet or exceed your expectations.

Frequently Asked Questions (FAQs)

1. How does interpolation affect part precision?

Interpolation directly impacts precision by ensuring the tool follows the exact design path. Advanced interpolation methods like 5-axis interpolation minimize errors from multiple setups and adjust for real-time variables (like tool wear and thermal expansion), allowing for tolerances as tight as ±0.001mm. Without interpolation, parts would have jagged edges, misaligned features, or inconsistent dimensions.

2. Which interpolation type is best for my part?

The right interpolation type depends on your part’s design:

Linear interpolation for straight lines and flat surfaces.

Circular interpolation for arcs and circles.

Helical interpolation for threads and spiral features.

Cubic spline interpolation for free-form, organic shapes.

5-axis interpolation for complex, multi-angle parts that require single-setup machining.

GreatLight’s engineers can help you select the optimal method based on your design, budget, and lead time requirements.

3. Can interpolation reduce machining time?

Yes. Advanced interpolation methods like 5-axis interpolation eliminate the need for multiple setups, reducing downtime between operations. Additionally, smooth, continuous tool paths allow for higher feed rates without compromising quality, further cutting machining time. GreatLight has seen time reductions of up to 50% for complex parts when switching from 3-axis to 5-axis interpolation.

4. Do all CNC machines support advanced interpolation?

No. Lower-end 3-axis CNC machines may only support linear and basic circular interpolation, while high-end 4-axis and 5-axis machines support more advanced methods like helical, spline, and 5-axis interpolation. GreatLight’s fleet includes 127 precision machines, including state-of-the-art 5-axis CNC centers that support all advanced interpolation types.

5. How does GreatLight ensure interpolation accuracy?

GreatLight uses several measures to ensure interpolation accuracy:

High-quality CNC controllers with advanced interpolation algorithms.

Regular calibration of all equipment to maintain axis alignment and precision.

In-process inspection using precision measurement tools like coordinate measuring machines (CMMs) to verify tool path accuracy.

A rigorous quality control process aligned with ISO 9001:2015 and IATF 16949 standards.

If any quality issues arise, GreatLight offers free rework or a full refund, ensuring client satisfaction.

6. What industries benefit most from advanced interpolation?

Industries that require complex, high-precision parts benefit the most, including aerospace, automotive (especially electric vehicles), medical devices, robotics, and high-end consumer electronics. GreatLight has deep experience in all these sectors, with case studies demonstrating how advanced interpolation has solved critical manufacturing challenges for clients.