Understanding Coining and CNC Machining: A Technical Deep Dive

In the realm of precision manufacturing, the question often arises: can you coin parts in a CNC machine? The short, direct answer is no, you cannot perform the traditional metalworking process of “coining” on a standard CNC milling or turning center. However, this question opens the door to a crucial discussion about process capabilities, definitions, and how modern CNC technology can achieve similar—and often superior—results for applications where coining might traditionally be considered.

To understand why, we must first define our terms precisely.

What is Coining in Metalworking?

Coining is a high-precision, cold-forming process. It involves placing a metal blank (usually at room temperature) between two hardened tool steel dies and applying an extreme amount of pressure—often thousands of tons. This pressure causes the metal to flow plastically into the fine details of the die cavities, replicating intricate features, textures, or lettering with exceptional accuracy and creating a smooth, work-hardened surface.

Key characteristics of traditional coining:

High Tonnage: Requires dedicated mechanical or hydraulic presses.

Compressive Forming: Metal flows under compressive stress, not by material removal.

Excellent Surface Finish: Produces very smooth, often mirror-like surfaces.

Dimensional Stability: Creates parts with minimal springback and tight tolerances.

Work Hardening: The process increases the surface hardness and strength of the part.

A classic example of coining is the production of coins, medals, and precision stamped parts like electrical contacts or micro-gears.

Why a Standard CNC Machine Cannot “Coin”

A CNC (Computer Numerical Control) machining center, whether 3-axis, 4-axis, or 5-axis, is fundamentally a material subtraction technology. It uses rotating cutting tools (end mills, drills, etc.) to remove material from a solid block or pre-form to achieve a desired geometry. It does not apply the omnidirectional, compressive force required to make metal flow into a die cavity.

The core mismatch is:

CNC Machining: Material Removal (Subtractive Manufacturing)

Coining: Material Displacement/Flow (Forming Process)

Attempting to use a CNC spindle to apply coining-level pressure would result in catastrophic tool and machine failure. They are engineered for entirely different physical principles.

The CNC Machining Alternative: Precision for Complex Geometries

While you cannot coin on a CNC machine, CNC machining is overwhelmingly the preferred and more capable method for producing the vast majority of high-precision, complex parts for which coining might be considered too limited. This is where the true strength of advanced machining services, like those offered by GreatLight CNC Machining Factory, comes into play.

How CNC machining surpasses or complements coining in modern applications:

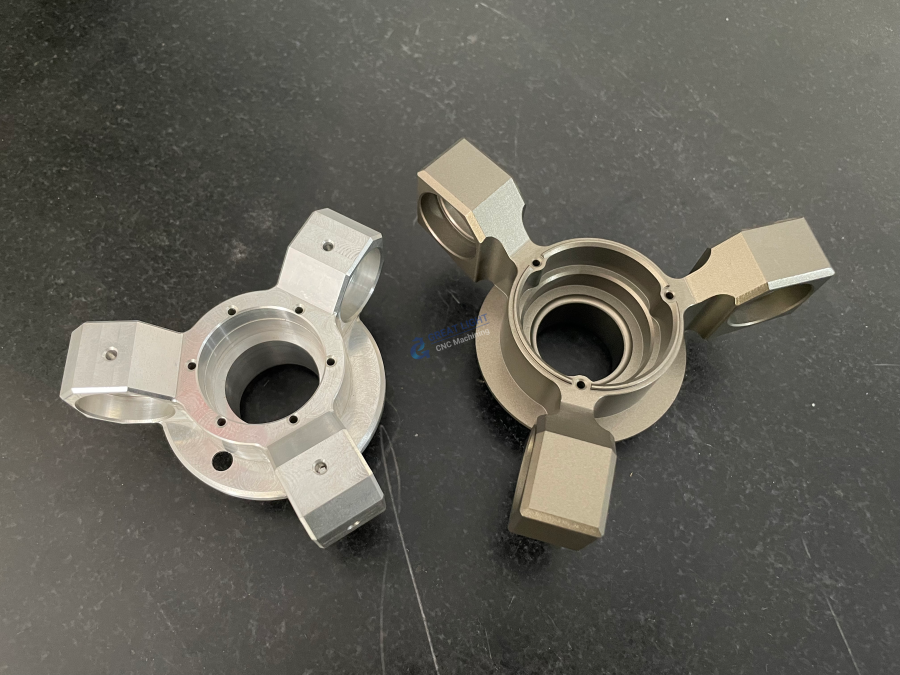

Unmatched Geometrical Freedom: Coining is limited to relatively simple, shallow, and symmetrical forms that can be ejected from a die. Precision 5-axis CNC machining services{:target=”_blank”} can produce incredibly complex, three-dimensional, undercut, and organic geometries that are impossible to coin. Think aerospace impellers, medical implants, or intricate mold cores.

Rapid Prototyping and Iteration: Creating a hardened coining die is expensive and time-consuming. CNC machining allows for direct production of a part from a CAD model in hours or days, with minimal setup cost. This is ideal for design verification, functional testing, and low-volume production.

Material Versatility: Coining is typically restricted to ductile metals like certain alloys of aluminum, brass, copper, and low-carbon steels. CNC machining can handle a vastly wider range, including hardened tool steels, titanium, Inconel, engineering plastics, and composites.

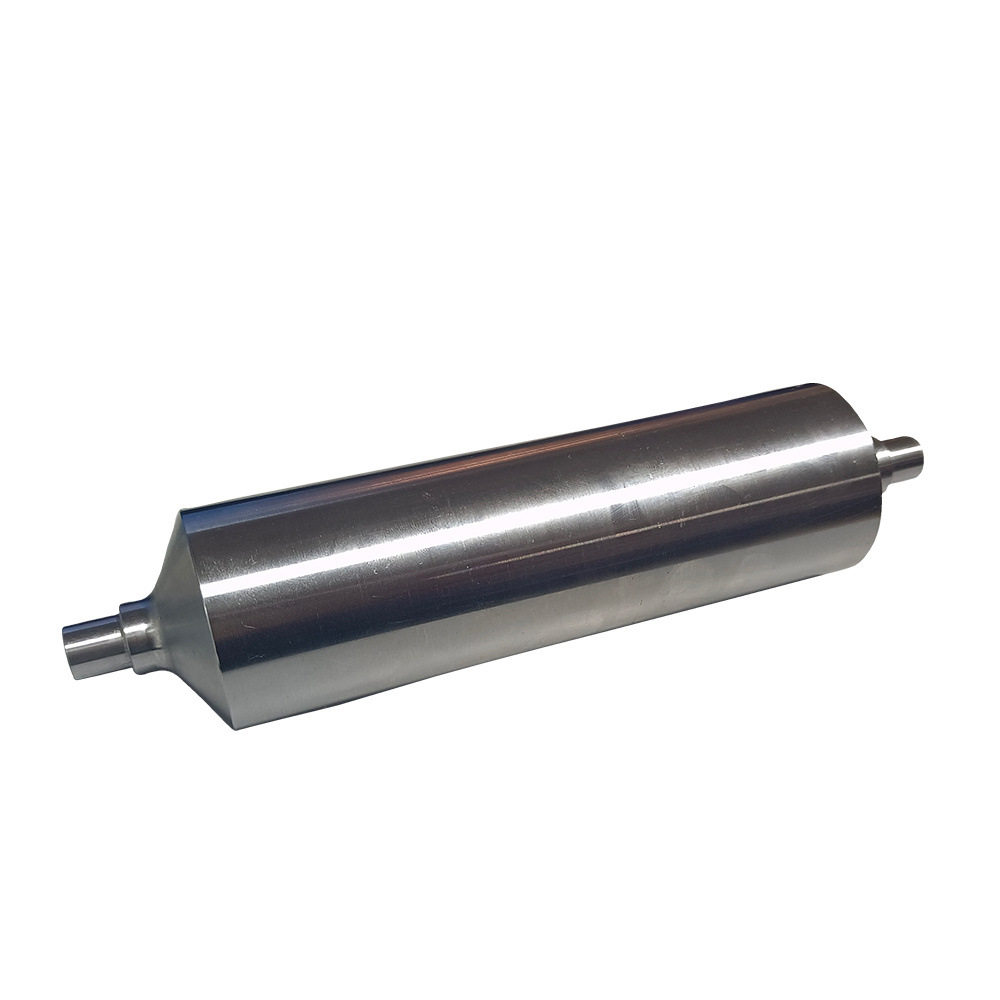

Exceptional Precision and Tolerance: Modern high-end CNC machines, especially 5-axis models, can achieve tolerances that meet or exceed those of coining (±0.001mm / 0.00004″ is attainable), but on far more complex parts. The process is controlled digitally, eliminating variables like die wear (in the short term) and press alignment.

Surface Finish Versatility: While coining yields a specific smooth finish, CNC machining can generate a vast range of surface textures—from machined patterns and engravings to optically polished surfaces through subsequent post-processing like manual polishing, barrel tumbling, or abrasive flow machining.

When is Coining the Right Choice?

Coining retains its niche for very high-volume production of simple, small, and flat parts where its strengths are paramount:

Mass Production: Once the die is made, each part cycle is extremely fast and cost-effective at volumes of hundreds of thousands or millions.

Micro-feature Replication: Excellent for ultra-fine details like micro-textures, security patterns, or razor-sharp lettering on a planar surface.

Specific Mechanical Properties: When the work-hardening effect and grain structure resulting from the cold flow process are critical to the part’s function.

The GreatLight Metal Approach: Integrating Knowledge for Optimal Solutions

At GreatLight CNC Machining Factory, our expertise lies in selecting and executing the optimal manufacturing process for the client’s requirement. Our role often involves consulting with engineers to determine if their design, initially conceived for a forming process, can be made more robust, lightweight, or functional through precision machining.

Our typical analysis for a “coining-type” part request involves:

Analyzing the 3D CAD Model: Is the geometry suitable for machining? Are there deep, thin cavities that would be better formed?

Evaluating Volume and Cost: For low to medium volumes, CNC machining is almost always more economical. For extremely high volumes, we might advise on sourcing for coining or recommend a hybrid approach.

Assessing Material and Tolerance: Can the required material be machined to the specified tolerance more effectively than it can be coined?

Considering a Hybrid Workflow: In some cases, the optimal solution involves CNC machining the precision coining dies themselves. We use our high-speed 5-axis CNC and precision EDM (Electrical Discharge Machining) equipment to manufacture intricate, hardened steel dies with the required surface finish and tolerances for coining or stamping processes. This leverages our core competency in precision to enable another manufacturing method.

Conclusion

So, can you coin parts in a CNC machine? Technically, no. The processes are fundamentally different. However, for the overwhelming majority of applications requiring high precision and complexity—from automotive sensors and robotic end-effectors to medical device components—CNC machining is not just a viable alternative but a superior and more flexible manufacturing solution.

The evolution of manufacturing is not about one process replacing another entirely, but about applying deep technical knowledge to match the perfect technology to the design challenge. Companies like GreatLight Metal thrive by providing this expertise, ensuring that whether a part requires the extreme pressure of a coining press or the digital precision of a 5-axis CNC mill, the client receives a component that meets the highest standards of quality, performance, and value.

Frequently Asked Questions (FAQ)

Q1: If I have a part that is currently coined, can it be converted to CNC machining?

A: In most cases, yes. Our engineers can analyze the coined part’s design, function, and material. Often, we can redesign it for manufacturability (DFM) via CNC, potentially improving the design, reducing weight, or integrating multiple coined parts into a single machined assembly. The feasibility depends on geometry, volume, and material.

Q2: Can CNC machining achieve the same smooth, “finished” surface as a coined part?

A: Yes, through a combination of high-quality machining with sharp tools, fine step-overs, and post-processing techniques like polishing, buffing, or electropolishing, we can achieve surface finishes (Ra values) that meet or exceed those of coined parts.

Q3: For creating textured surfaces (like leather grain, logos), is CNC or coining better?

A: For prototyping and low-to-medium volumes, CNC engraving or texturing is faster and more cost-effective. For imprinting extremely fine, shallow textures on millions of identical parts (e.g., on a consumer electronics bezel), coining with a CNC-machined die may be the optimal high-volume solution.

Q4: Which process holds tighter tolerances, coining or CNC machining?

A: Both are capable of extremely tight tolerances (±0.025mm or better). However, CNC machining generally offers more consistent control over a wider range of dimensions on a complex part. Coining excels at holding tight tolerances on planar features and thickness.

Q5: How do I decide which process to use for my project?

A: This is where partnering with an expert manufacturer is critical. GreatLight Metal provides free DFM analysis. By sharing your CAD model, intended volume, material, and performance requirements, our engineers can recommend the most efficient and reliable process, whether it’s CNC machining, a forming process, or a combination of both. Connect with our team on LinkedIn{:target=”_blank”} to start a conversation about your specific project needs.