Mastering the Startup: A Professional Guide to Powering Up Your CNC Milling Machine

The moment of starting a CNC milling machine is more than just flipping a switch; it is the critical first step in a symphony of precision. A proper startup procedure is the cornerstone of safe operation, equipment longevity, and, ultimately, the achievement of the micron-level accuracy demanded in modern manufacturing. Whether you are a seasoned machinist or an engineer overseeing production, a systematic approach to starting your CNC mill is non-negotiable. This guide will walk you through a professional, step-by-step startup sequence, embedding the principles of safety, precision, and preventive maintenance that define world-class workshops like ours at GreatLight Metal.

H2: The Philosophy Behind a Proper Startup: Beyond the Power Button

A successful startup transcends mere functionality. It is a diagnostic ritual and a preparatory phase that sets the stage for the entire production run. Rushing this process can lead to catastrophic tool crashes, subpar surface finishes, dimensional inaccuracies, and accelerated wear on spindles and guideways. The goal is to ensure the machine, the tooling, the workpiece, and the program are in perfect harmony before the first chip is made.

H2: Pre-Startup Checklist: The Foundation of Safe Operation

Before any electrical power is applied, a thorough visual and mechanical inspection is essential.

H3: 1. Workspace and Machine Environment

Cleanliness: Ensure the work area is free of oil, coolant, chips, and loose tools. A clean environment prevents slips and contamination.

Machine Exterior: Wipe down the machine surfaces, especially the control panel and door seals. Check for any signs of coolant or oil leaks.

Safety Equipment: Verify that emergency stop buttons are accessible and not engaged. Ensure machine guarding is in place and functional.

H3: 2. Mechanical and Fluid System Checks

Lubrication: Check the central lubrication system’s oil level and manually lubricate guideways and ball screws if the machine has been idle for an extended period, as per the manufacturer’s manual.

Coolant System: Inspect the coolant tank level and concentration. A poorly maintained coolant can lead to poor finish, corrosion, and biological growth.

Hydraulic/Pneumatic Pressure: For machines with hydraulic chucks or pneumatic tool changers, verify that system pressures are within the specified range.

H3: 3. Tooling and Workholding Preparation

Tool Presetting: Ideally, tools should be pre-set offline using a tool presetter to establish accurate length and diameter offsets. This drastically reduces machine setup time and potential for error.

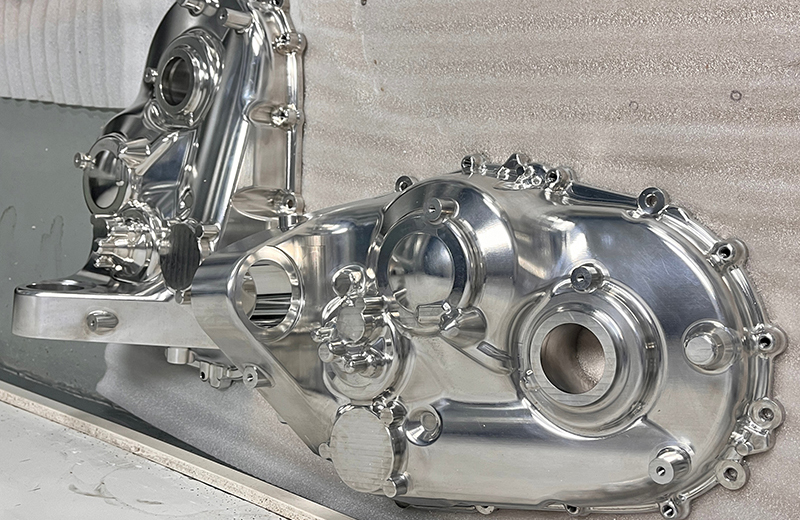

Tool Holder Inspection: Visually inspect tool holders for cleanliness, damage, and proper pull stud condition. A speck of dirt on the taper can cause TIR (Total Indicator Runout) errors.

Workholding Security: Double-check that the vise, fixture, or chuck is securely mounted to the machine table and that the workpiece is clamped correctly and squarely.

H2: The Step-by-Step Startup Sequence

With the pre-checks complete, you can proceed with the power-up sequence.

H3: Phase 1: Powering Up and Homing the Machine

Main Power Switch: Activate the main electrical disconnect switch, usually located on the rear or side of the machine cabinet.

Control Power: Turn on the CNC control unit. The screen will boot up, running through its system diagnostics. Do not interrupt this process.

Machine Homing/Reference Return: This is the most critical step after power-up. Execute the “Reference Return” or “Home All Axes” cycle. This establishes the machine’s coordinate system zero by moving each axis until it contacts its limit switch. Never skip homing. Operating without a valid reference point can lead to a crash.

H3: Phase 2: Warm-Up and System Verification

Spindle Warm-Up: Especially crucial for high-precision machines and high-speed spindles. Run a manufacturer-recommended warm-up program, which typically involves rotating the spindle at progressively higher speeds. This allows the spindle bearings to reach a stable thermal equilibrium, ensuring consistent precision throughout the job.

Axis Warm-Up: Jog all axes (X, Y, Z, and any rotary axes) through their full travel at a moderate feed rate. This redistributes lubrication along the guideways and ball screws.

H3: Phase 3: Tool and Workpiece Setup on the Machine

Load Tools into Magazine: Load the pre-set tools into the machine’s automatic tool changer (ATC) magazine in the order specified by your CNC program (T1, T2, etc.).

Set Work Offsets (G54, G55, etc.): Using an edge finder, probe, or touch probe system, establish the workpiece’s position in the machine coordinate system. This defines the program’s zero point on your part.

Input/Verify Tool Offsets: Manually input the length and diameter offsets from your presetter, or use the machine’s probe to measure tool lengths directly in the spindle. This data tells the control the exact position of the cutting edge relative to the spindle nose.

H3: Phase 4: Program Verification and Dry Run

Load the CNC Program: Transfer the program (G-code) via network, USB, or direct input.

Graphical Simulation: Use the control’s built-in tool path verification software to visually simulate the entire machining process. Check for any unexpected movements, collisions, or rapid traverses through the workpiece.

Dry Run (Optional Stop & Reduced Feed):

Lock the spindle and disable the coolant.

Reduce the rapid traverse and feed rate overrides to 25-50%.

Single-step through the program, watching the axis positions and distance-to-go readings. This “air cut” confirms the program logic and fixture clearance.

H2: Execution and First-Article Inspection

Final Safety Check: Ensure the doors are closed, coolant is directed properly, and all personnel are clear.

Cycle Start: Initiate the full automated cycle. Closely monitor the first few minutes of machining, especially the initial tool engagement.

First-Article Inspection: After the first part is complete, perform a comprehensive inspection using calibrated metrology tools (micrometers, calipers, CMM). Verify all critical dimensions against the drawing before committing to a full batch run.

This meticulous startup protocol is ingrained in the culture at GreatLight Metal. Our operators treat every machine startup—from our high-speed 3-axis mills to our advanced 5-axis CNC machining centers—with the same disciplined rigor. This discipline is what allows us to consistently hit tolerances of ±0.001mm and guarantee the reliability of every component we produce, from aerospace actuators to life-critical medical device prototypes.

Conclusion: Precision is a Habit, Starting from Power-Up

Knowing how to start a CNC milling machine correctly is a fundamental skill that separates proficient workshops from exceptional ones. It is a process that blends technical knowledge with disciplined routine. By investing time in a thorough startup—encompassing checks, warm-up, verification, and validation—you invest in the safety of your personnel, the health of your capital equipment, and the flawless quality of your output. For organizations where machining is a core competency but not their primary focus, partnering with a manufacturer that has institutionalized these best practices can be transformative. It transforms the procurement of precision parts from a variable-cost challenge into a reliable, value-adding stream of high-integrity components.

Frequently Asked Questions (FAQ)

H3: Q1: How long should a typical CNC machine warm-up last?

A: There is no one-size-fits-all answer; it depends on spindle size, bearing type, and ambient temperature. A standard VMC might need 10-15 minutes, while a high-precision, high-speed spindle may require 30 minutes or more. Always consult your machine manual. At GreatLight Metal, we use standardized warm-up cycles tailored to each machine’s specifications to ensure thermal stability before precision work begins.

H3: Q2: What is the single most common mistake made during startup?

A: The most common and dangerous mistake is failing to perform a proper reference return (homing) after power-up. Without this, the machine has no established coordinate zero, and any movement or program execution is based on an unknown position, almost guaranteeing a crash.

H3: Q3: Can I skip the dry run if I’ve simulated the program on CAM software?

A: It is highly discouraged. While CAM simulation is excellent for verifying toolpath geometry and basic collision avoidance, it cannot account for all real-world variables such as slight fixture inaccuracies, tool holder deflection, or post-processor errors. The dry run on the actual machine is the final, irreplaceable verification step.

H3: Q4: What daily maintenance should be performed alongside the startup procedure?

A: Key daily tasks include: checking and topping off coolant and lubrication levels, clearing chips from the chip pan and way covers, checking hydraulic/pneumatic filters, and performing a quick visual inspection of tools and workholding for damage or wear. A logbook for these checks is a best practice.

H3: Q5: My machine has been idle over a weekend. Does the startup procedure change?

A: For short idle periods (a weekend), the standard procedure is sufficient, with perhaps slight emphasis on the warm-up cycle. For extended shutdowns (weeks or months), more extensive procedures are needed, such as running a longer lubrication cycle, checking for corrosion, and potentially re-calibrating the machine. For mission-critical production, partnering with a certified manufacturer like GreatLight Metal, which maintains continuous operational protocols, eliminates these variables from your supply chain. For more insights into our operational excellence, follow our professional updates on LinkedIn.