When clients first step onto the production floor of a precision machining supplier like ours at GreatLight Metal, the sight that often greets them is both imposing and intricate: rows of substantial, enclosed cabinets humming with activity, with robotic arms moving spindles in complex, multi-axis dances. This is the modern CNC machine. But what you see on the outside is merely the shell; the true essence lies in the orchestrated symphony of components within and the unparalleled capability it represents for bringing your most complex part designs to life.

H2: The External Anatomy: More Than Just a “Big Box”

At first glance, a typical CNC machining center—especially the advanced 5-axis variants we specialize in—resembles a large, sturdy cabinet or enclosure, often the size of a van. This robust exterior is fundamental, serving critical purposes:

Rigid Frame & Base: Usually made of heavily ribbed cast iron or polymer concrete, this massive structure is the foundation. It absorbs vibrations from high-speed cutting, ensuring the microscopic levels of precision we guarantee (down to ±0.001mm) are not compromised. It’s the “anchor” of stability.

Full Enclosure: Transparent polycarbonate doors surround the working area. This is a critical safety feature, containing coolant, metal chips (swarf), and any potential tool breakage. It also helps in maintaining a stable thermal environment around the workpiece, a key factor in holding tight tolerances.

The Control Panel (CNC Controller): This is the “brain” of the operation. It features a screen and keypad where machinists and programmers input, monitor, and adjust the machining process. Brands like Siemens, Heidenhain, or Fanuc are common, and their interfaces are the direct link between your digital CAD model and the physical part being created.

Tool Magazine: Often located on the side or top of the machine, this is a rotating carousel or chain-type magazine that can hold dozens, sometimes hundreds, of different cutting tools. This allows for complex parts to be machined in a single setup, as the machine can automatically change tools from a drill to an end mill to a tapping head in seconds.

H3: Inside the Enclosure: Where Precision is Forged

Open the door (with the machine safely stopped), and the true workshop is revealed. This is where the transformation from raw material to precision component happens.

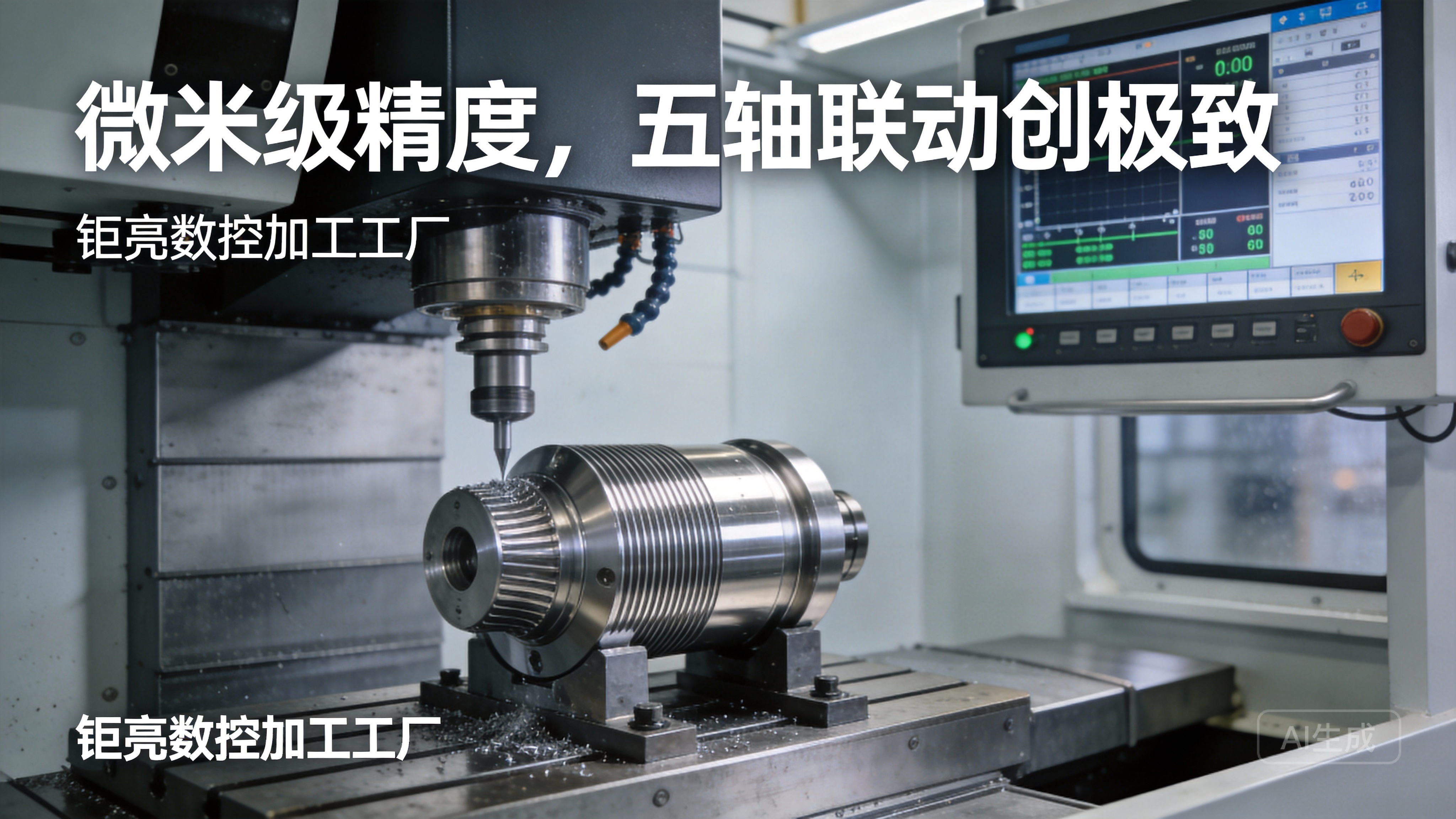

The Worktable & Chuck: This is where your raw material—be it a block of aluminum, titanium, or engineering plastic—is securely fastened. In a 3-axis machine, this table typically moves in the X and Y directions. In our core 5-axis CNC machining setups, this table is often a trunnion or swivel-head mechanism that can tilt and rotate the part to almost any angle, allowing the tool to approach from five sides simultaneously.

The Spindle: This is the heart of the cutting action. It’s a high-precision motor that rotates the cutting tool at tremendous speeds—often from 10,000 to 30,000 RPM or higher. The sound of a spindle under load is a distinct, high-pitched whir. Its quality directly impacts surface finish, precision, and the ability to cut hard materials.

The Cutting Tool: Held in the spindle by a precision collet or holder, this is the “scalpel.” From simple end mills to complex form tools, they come in thousands of shapes and sizes, often coated with ultra-hard materials like titanium nitride (TiN) or diamond-like carbon (DLC).

The Axis Slides & Guideways: These are the ultra-precise rails and ball screws that move the spindle and/or the table with micron-level accuracy. They are lubricated and protected from debris to ensure smooth, frictionless motion over millions of cycles.

Coolant System: High-speed machining generates heat. A network of nozzles floods the cutting area with coolant (often an oil-water emulsion) to lubricate the cut, evacuate chips, and critically, manage thermal expansion of both the tool and workpiece to maintain dimensional stability.

H2: A Landscape of Variety: Not All CNC Machines Look Alike

The description above fits a standard vertical machining center (VMC). However, a full-service manufacturer like GreatLight Metal operates a diverse fleet, each with a specialized profile:

CNC Lathes (Turning Centers): These have a different silhouette. The workpiece rotates in a chuck, while stationary cutting tools on a turret move in to shape it. They are ideal for cylindrical parts like shafts, pins, and connectors.

5-Axis Mill-Turn Centers: These are the ultimate fusion machines, combining the capabilities of a lathe and a 5-axis mill. They look particularly complex, with multiple spindles, turrets, and often a second working area, allowing complete machining of extraordinarily complex parts in one clamping.

Wire EDM (Electrical Discharge Machining): This looks entirely different. It features a tank of deionized water and a thin, electrically charged wire that precisely erodes conductive material. It’s used for ultra-fine, burr-free cuts in hardened steel or for creating intricate punch and die sets.

Swiss-Type Lathes: These are long, slender machines designed for high-volume production of small, complex turned parts. The material bar stock feeds through a guide bushing, providing extreme support and accuracy for parts like medical device components.

H3: Why the “Look” Matters: It’s a Direct Reflection of Capability

For a client, understanding what a CNC machine looks like is more than an academic exercise. The physical attributes are direct indicators of a supplier’s capability:

Size and Rigidity: The mass and construction of the frame correlate directly with the stability needed for heavy cuts and large-part machining. Our large-format 5-axis machines, for instance, are engineered to handle parts up to 4000mm without sacrificing precision.

Age and Condition: Well-maintained, modern machines with clean interiors and digital controllers signal a commitment to consistent quality and the ability to handle complex programming.

Tooling and Workholding: A machine equipped with a high-capacity tool magazine and a variety of precision vises, chucks, and custom fixtures indicates preparedness for complex, multi-operation jobs and efficient production.

Integration and Automation: The presence of robotic arms for part loading/unloading or pallet changers points towards a facility geared for higher-volume production and reduced lead times.

Conclusion: The Machine as Your Strategic Partner

So, what does a CNC machine look like? It looks like potential. It is the physical manifestation of digital design intent. When you partner with a manufacturer like GreatLight Metal, you are not just renting time on a metal-cutting box. You are leveraging an integrated system of advanced mechanical engineering, digital control, material science, and deep technical expertise. Our factory floor, populated with over 127 pieces of precision equipment including advanced 5-axis CNC machining centers from brands like DMG Mori and Beijing Jingdiao, is a testament to our investment in becoming a true extension of your engineering team. The appearance, maintenance, and sophistication of these machines are the first and most tangible assurances that your most challenging precision part requirements will be met with reliability and excellence.

FAQ: Frequently Asked Questions

Q1: Is a bigger CNC machine always better?

A: Not necessarily. “Better” is defined by your part’s requirements. A massive machine is essential for large aerospace structural components but would be inefficient and costly for machining small, intricate medical implants. The key is matching the machine’s work envelope, precision level, and dynamic capabilities to the part’s size, geometry, and material. A full-service provider like GreatLight Metal maintains a portfolio of machines to optimally match the tool to the task.

Q2: Why are 5-axis machines often enclosed differently than 3-axis machines?

A: 5-axis CNC machining involves more complex, sweeping movements of both the spindle and the worktable. The enclosure must be designed to accommodate this wider range of motion without interference, while still safely containing chips and coolant. The internal mechanism (trunnion table, swivel head) also takes up more space, defining the machine’s internal architecture.

Q3: Can I tell how precise a machine is just by looking at it?

A: You can gather strong clues. Signs of high precision include: impeccable cleanliness (contamination causes wear), evidence of regular maintenance, the use of climate-controlled environments or thermal compensation systems, and the presence of high-end metrology equipment (like laser interferometers) used for calibration. Ultimately, the proof is in the parts produced and the supplier’s certified quality data, such as our adherence to ISO 9001:2015 and IATF 16949 standards.

Q4: What’s the difference between the “CNC controller” and the computer used for programming?

A: They are distinct but connected. The programming is done on an offline CAM (Computer-Aided Manufacturing) workstation, where engineers convert your 3D CAD model into a toolpath program (G-code). This program is then transferred to the CNC machine’s onboard controller. The controller is the dedicated industrial computer that executes the G-code in real-time, precisely coordinating all motors, spindles, and auxiliary functions of the physical machine.

Q5: How does a manufacturer like GreatLight Metal ensure consistency across multiple machines and shifts?

A: Consistency is governed by systems, not just machines. It is achieved through:

Standardized, documented processes for every job.

A centralized, controlled digital tool library.

Regular machine calibration and preventive maintenance schedules.

Operator training and certification programs.

A robust Quality Management System (QMS) with in-process inspections and final verification using CMMs (Coordinate Measuring Machines) and other precision instruments. Our multiple ISO and IATF certifications are independent validations of this systematic approach to consistent quality.

For more insights into our capabilities and how we translate advanced machinery into client success, feel free to connect with our team on LinkedIn.