In this article we will show you howConvert F3D files to STL format. However, before we begin the conversion process, let’s take a closer look at the differences between native and non-native file formats.

Native and non-native formats

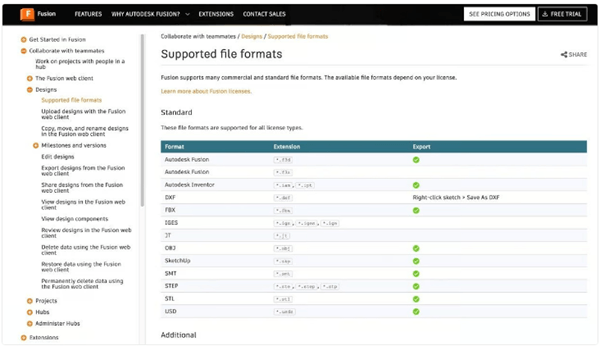

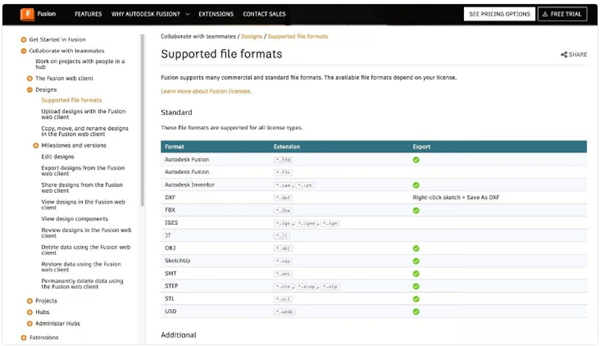

Many file formats are customized to store data for a specific application (source:Autodesk)

Native formats and non-native formats refer to the classification of file types based on their availability in third-party programs.

native format

Most major design software programs have their own file formats for storing application-specific data; these formats are called native file formats. An example isBlend format, which is the native format of the Blender modeling tool and is used to store program-specific data. It’s generally best to save your work in the native format of the program you’re using, provided you don’t need to move the files to another program.

F3D is Fusion’s native 3D model format. This type of file is primarily generated and exported by Fusion, and although it is a very useful format, its use outside the program is limited.

non-native format

Most programs can import and export a range of files in addition to their own files. Formats supported in this way are called non-native formats. Using a non-native format may mean that you won’t be able to save as much program-specific data to the file, but the data you do save will be accepted in more places.

For3D models, especially in the world of 3D printing and CAD, STL is a popular file format compatible with many different applications, from design software to 3D slicers.

Why convert

most3D slicers (like Cura) do not accept models in F3D format (Source: Guilherme Schendel via All3DP)

If you design a file in one program and need to use it in another program, you mustConvert F3D to STL (or other combination of file types). Since F3D is Fusion specific, you may need to convert any file to this format in order to use your model for other purposes.

For example, let’s say you areA part is designed in Fusion or an F3D file is downloaded from a design repository and you want to convert the file to G-code for 3D printing. To do this, a 3D slicer is used to prepare the model for printing. Unfortunately, most 3D slicers are limited to a few major formats, such as STL, OBJ, and 3MF, and cannot read F3D files or any other formats native to the specific software.

In this case you need to convert the originalConvert F3D files to more widely accepted formats such as STL. There are several ways to do this, but the simplest and most reliable is to use Fusion itself.

How to convert

Export the entire model at once (source:Guilherme Schendel via All3DP)

If your part is inDesigned in Fusion, exporting it to STL should be a simple process. Below we provide a step-by-step guide to convert F3D models to STL format using Fusion. If you don’t have Fusion, you can check out the different versions and download the one that best suits your needs. Our tutorial will begin assuming you have downloaded and configured Fusion.

Export full model

The following instructions will generate aSTL files. If your model consists of multiple parts, such as bodies or components, all the parts will be exported together to STL.

1、OpenAfter Merging, click the file icon in the upper left corner of the screen and select “Open…” from the drop-down menu (or press “Ctrl+O”).

2、Find the one you need to convertF3D and open it.

3、Make sure the imported design is correct, then click the file icon and select“Save” (or use “Ctrl+S”) to save it to Fusion. If you use F3D found online, you can save it even without editing because you can save it from your hard drive to Autodesk Cloud. On the other hand, if you’re working on a design that you created from scratch, the Save feature won’t work until you’ve made a few changes.

4、Again from the File menu, select“Export…” and a pop-up page will appear.

5、existName your model under “Name:” and select “STL File (*.stl)” under “Type:”.

6、Select the location where you want to save the template and click“Export”.

Export different parts of the model

Export different parts of the model as separate files (source:Guilherme Schendel via All3DP)

If you need to export different sections to separate files to have more flexibility when trimming, you have two options

Use the export command

1、Use the eye icon to the left of an item name in the Project Browser to hide or show a body or component.

2、Only the required elements appear on screen, following the same steps as for exporting the full model. This way only active items will be exported.

Use the Save as Mesh tool

1、on the left side of the workspaceFind the body to export in the Fusion browser.

2、Right-click the widget; this will open a drop-down menu. click“Save as grid”.

3、This will highlight the subject and a menu will appear on the right side of the screen. Here you can select the file format, dimensions and other parameters.

4、From there, simply follow the steps in the processYou can export the complete model in 4 steps.

There you go, you have now completed the conversion process! As shown in the pop-up window, the conversion may take a few minutes, but yourThe STL file should appear in the determined location when ready.

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.