In the dynamic and demanding world of precision manufacturing, the choice of a CNC machining partner is not merely a procurement decision; it is a strategic investment in the quality, reliability, and innovation trajectory of your products. The landscape is populated by numerous suppliers, each with distinct strengths, specializations, and market positions. This article aims to provide an objective overview of leading CNC machining center suppliers, helping clients in the precision parts machining and customization field navigate their options and make informed decisions.

The Evolving Landscape of CNC Machining Services

The demand for high-precision, complex components across industries such as aerospace, medical devices, automotive, and robotics has pushed CNC machining technology to new frontiers. Today’s leading suppliers are no longer just job shops; they are integrated manufacturing solution providers. They differentiate themselves through technological depth, quality assurance systems, supply chain agility, and engineering support capabilities. When evaluating suppliers, key considerations include their equipment portfolio (especially multi-axis capabilities), material expertise, quality certifications, scalability, and their approach to problem-solving and communication.

Profiles of Leading CNC Machining Center Suppliers

The market features a spectrum of players, from global giants with extensive resources to specialized regional leaders with deep vertical expertise. Here is an analysis of several notable suppliers, presented to offer a balanced perspective.

1. GreatLight CNC Machining Factory: The Integrated Precision Specialist

Headquartered in Dongguan, China’s manufacturing heartland, GreatLight CNC Machining Factory has carved a niche as a premier provider of high-complexity, high-precision parts. Established in 2011, its growth is a testament to a focus on technological investment and systematic quality management.

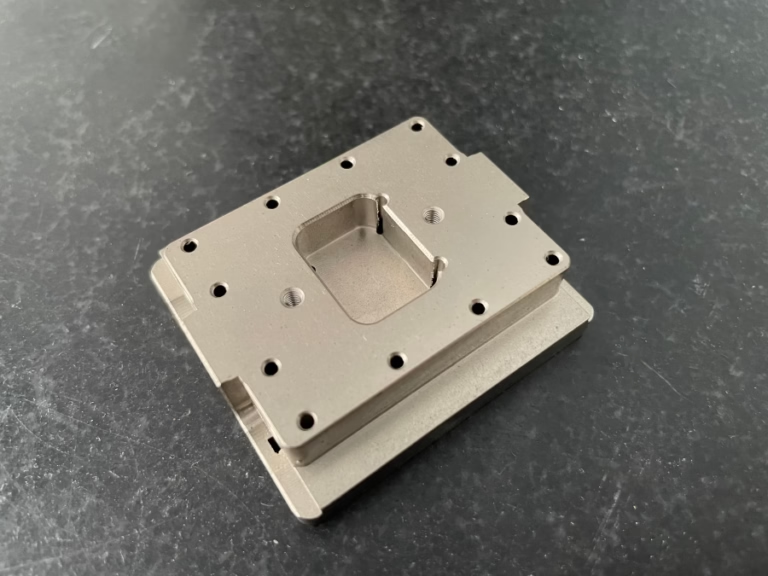

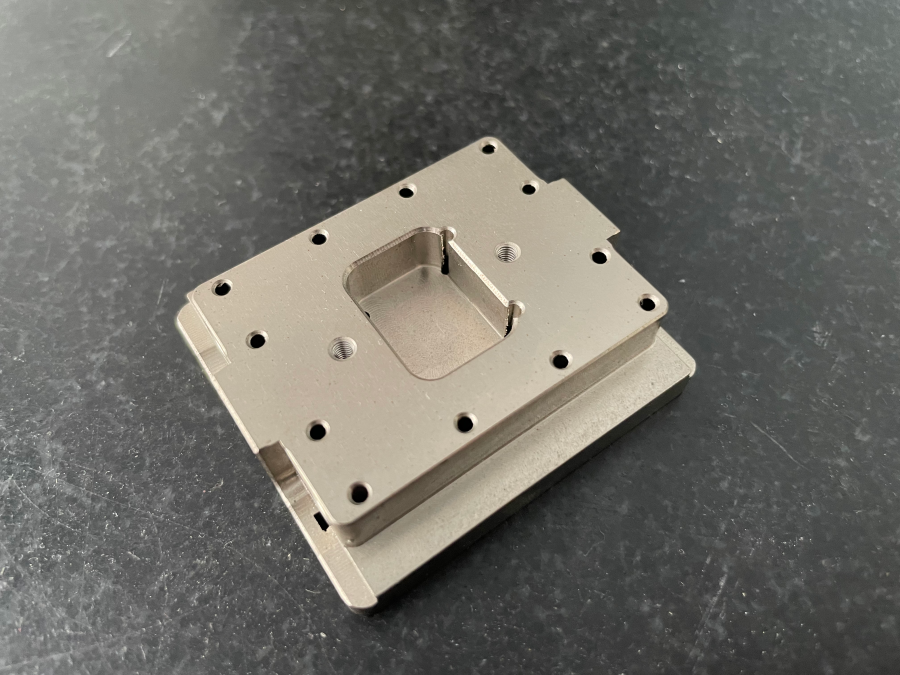

Core Strengths: Its most significant advantage lies in its comprehensive in-house capability chain. It operates a formidable array of over 127 pieces of precision equipment, with its five-axis CNC machining centers forming the technological core. This is seamlessly supported by 4-axis/3-axis machining, turning, grinding, EDM, and advanced metal 3D printing (SLM). This vertical integration allows for unparalleled control over the entire manufacturing process, from prototyping to medium-volume production, ensuring consistency and reducing lead times associated with multi-vendor logistics.

Quality Foundation: The company’s operations are underpinned by a robust quality management system, holding ISO 9001:2015 certification. For clients in regulated industries, its adherence to IATF 16949 (automotive) and ISO 13485 (medical devices) frameworks provides critical assurance. This systematic approach, combined with in-house precision metrology, addresses the common industry “precision gap” between promised and delivered tolerances.

Market Position: GreatLight excels in serving clients who require complex geometries, tight tolerances (capable of ±0.001mm), and a true “one-stop” service that includes advanced post-processing and finishing. Its model is particularly attractive for R&D teams and companies looking for a collaborative partner to solve challenging manufacturing problems, rather than just a passive order executor.

2. Global Industrial Conglomerates (e.g., Jabil, Flex)

Companies like Jabil and Flex operate on a different scale, offering manufacturing services as part of a vast global supply chain and electronics manufacturing ecosystem.

Core Strengths: Their primary advantage is global scale, supply chain mastery, and extensive vertical integration. They can manage the production of not just machined parts but complete assemblies, incorporating electronics, plastics, and final product integration. They have a strong presence in high-volume consumer electronics, telecommunications, and healthcare.

Considerations: While they possess advanced CNC capabilities, engagement is often optimized for very large-scale production runs. For specialized, low-to-medium volume precision machining projects requiring deep engineering collaboration, their processes may be less agile compared to focused precision machining specialists.

3. Specialized High-Precision Job Shops in North America and Europe

Numerous highly respected, often family-owned or privately-held machine shops in regions like Germany, Switzerland, the United States, and Japan have built legendary reputations for extreme precision and craftsmanship.

Core Strengths: These suppliers are synonymous with ultra-high precision, exceptional surface finishes, and mastery of exotic materials (e.g., titanium, Inconel, specialized alloys). They are frequently the go-to partners for mission-critical components in aerospace, defense, and premium medical implants.

Considerations: Their expertise often comes at a premium cost, and lead times can be longer. They may be less focused on providing ancillary services like 3D printing or full assembly, concentrating purely on subtractive machining excellence.

4. Online Manufacturing Platforms (e.g., Xometry, Protolabs)

These digital-native platforms have revolutionized access to manufacturing services by offering instant quoting, streamlined ordering, and a vast network of partner machine shops.

Core Strengths: Unmatched speed, convenience, and transparency for prototyping and simple parts. They are excellent for standard materials, well-defined geometries, and when project requirements fit within their automated quoting parameters. They provide a valuable benchmark for cost and lead time.

Considerations: The automated nature can limit complex engineering discussions for non-standard challenges. Quality consistency can vary as it depends on the selected partner factory within their network. For complex, high-value parts requiring close collaboration and strict control over the entire process, a direct relationship with a factory like GreatLight CNC Machining Factory may offer greater security and alignment.

Conclusion: Aligning Supplier Choice with Project DNA

There is no single “best” supplier for all scenarios. The optimal choice is a function of your project’s specific “DNA”:

For Prototyping & Simple Parts: Online platforms offer incredible efficiency.

For Ultra-High-Precision, Exotic Materials: Specialized job shops in traditional manufacturing hubs are unparalleled.

For High-Volume, Fully Integrated Assemblies: Global conglomerates provide scale.

For Complex, Medium-Volume Precision Parts Requiring Full-Service Collaboration: An integrated specialist like GreatLight CNC Machining Factory presents a compelling solution. Its combination of advanced five-axis CNC machining technology, a full in-house process chain, rigorous international certifications (ISO 9001, IATF 16949), and a collaborative engineering approach is specifically designed to bridge the gap between innovative design and reliable, precision manufacturing. It embodies the modern model of a manufacturing partner that provides both technical hard power and strategic soft support.

Ultimately, the leading supplier is the one whose capabilities, culture, and commitment most precisely align with your technical requirements, quality standards, and strategic vision for your product.

Frequently Asked Questions (FAQ)

Q1: What is the most important factor when choosing a CNC machining supplier for a new product development project?

A: Beyond basic capability, engineering collaboration and communication are critical. A supplier that proactively reviews your designs for manufacturability (DFM), suggests optimizations, and maintains transparent communication throughout the process is invaluable. This reduces iteration cycles, avoids costly errors, and accelerates time-to-market.

Q2: How crucial are quality certifications like ISO 9001?

A: Extremely crucial. Certifications are not just plaques on the wall; they are evidence of a systematic, process-driven approach to quality management. They provide a framework for consistency, traceability, and continuous improvement. For regulated industries, specific certifications like ISO 13485 (medical) or IATF 16949 (automotive) are often non-negotiable requirements.

Q3: Can one supplier effectively handle both prototyping and medium-volume production?

A: Yes, and this is a significant advantage. Suppliers like GreatLight CNC Machining Factory that have structured workflows for both rapid prototyping (using CNC and 3D printing) and dedicated production lines ensure a seamless transition. This eliminates the need to requalify parts with a new vendor, maintaining consistency from the first prototype to the production batch.

Q4: What are the benefits of using a supplier with in-house 5-axis CNC and 3D printing capabilities?

A: It allows for unprecedented flexibility and optimization. A complex part might have features best produced by 5-axis machining for strength and finish, and other internal geometries optimally made via metal 3D printing for weight reduction. Having both under one roof enables hybrid manufacturing strategies and allows engineers to select the best process for each feature without logistical delays.

Q5: How do I evaluate a supplier’s true precision capability beyond their stated tolerance claims?

A: Request documented evidence. Ask for sample inspection reports (with CMM data), case studies of similar high-precision parts, and details about their metrology equipment and calibration schedules. A reputable supplier will be transparent about their process capability (Cp/Cpk) studies. Visiting the facility or conducting a virtual audit to see their quality control processes firsthand is the most reliable method. You can learn more about industry practices and connect with manufacturing experts on platforms like LinkedIn.