When diving into the world of modern manufacturing, a common and crucial question arises: What programming language do CNC machines use? The direct answer is G-code, the fundamental instruction set that drives computerized numerical control. However, this is merely the tip of the iceberg. For clients seeking precision parts machining and customization, understanding the ecosystem of CNC programming—from the core machine language to the advanced software that generates it—is key to evaluating a manufacturer’s capability, ensuring design intent is perfectly translated into physical reality, and ultimately, guaranteeing the success of your project.

The Universal Machine Tongue: G-Code and M-Code

At the very heart of every CNC mill, lathe, or 5-axis machining center lies an interpreter that reads a sequential, line-by-line set of commands. This is G-code (Geometric Code), often paired with M-code (Miscellaneous Function Code).

G-Code controls the geometry and movement of the machine. It dictates actions like:

Rapid positioning (G00): Move tool quickly to a position without cutting.

Linear interpolation (G01): Move tool in a straight line at a specified feed rate for cutting.

Circular interpolation (G02, G03): Cut arcs and circles.

Setting work coordinates, selecting planes, and defining units.

M-Code controls the auxiliary functions of the machine:

Spindle control (M03, M04, M05): Start/stop spindle rotation.

Coolant control (M07, M08, M09): Turn coolant on/off.

Tool change (M06): Command an automatic tool change.

Program end (M30): End program and rewind.

Think of G-code as the assembly language of manufacturing. It is highly standardized (following ISO 6983), yet every machine tool builder (Fanuc, Siemens, Heidenhain, Mitsubishi) adds its own proprietary extensions and nuances. A program written for one specific machine model may not run flawlessly on another without post-processing adjustment. This is where a machinist’s expertise becomes invaluable.

The Birth of Code: CAM Software is the True “Programming” Environment

While one could theoretically write G-code by hand for simple parts—a practice still used for troubleshooting or minor edits—virtually all complex precision components are programmed using CAM (Computer-Aided Manufacturing) software. This is the high-level “programming” environment where engineers and programmers work.

CAM software (like Siemens NX, Mastercam, Fusion 360, HyperMill) uses the 3D CAD model as its input. The programmer then:

Defines the raw stock material.

Selects cutting tools from a digital library.

Creates a sequence of machining “operations” (e.g., roughing, finishing, drilling).

Sets parameters like spindle speed, feed rate, and depth of cut.

Uses software simulation to visualize the entire machining process, detecting potential collisions or inefficiencies.

Once the strategy is perfect, the CAM software post-processes this information. The post-processor is a critical, machine-specific translator that converts the generic toolpaths into the flawless, optimized G-code that a particular five-axis CNC machining center expects. A well-configured post-processor is a sign of a mature and experienced manufacturer.

Beyond G-Code: The Role of Proprietary Languages and Conversational Programming

High-Level Proprietary Languages: Manufacturers like Siemens have developed advanced language extensions (e.g., Siemens SINUMERIK ShopTurn/ShopMill). These are more intuitive, parametric cycles that simplify programming for complex repeated features, effectively acting as a higher-level language that is later compiled down to machine-ready G-code.

Conversational CNC: Common on modern shop-floor controls, this allows machinists to program simple parts directly at the machine interface by answering prompts (e.g., “Drill a hole of diameter X at location Y”), bypassing the need for CAM for straightforward tasks. It emphasizes ease of use and quick turnaround.

Why This Technical Depth Matters for Your Custom Parts Project

Your choice of a machining partner hinges on their mastery of this entire programming chain. Here’s how it impacts your outcomes:

From Design to Reality with Fidelity: Complex free-form surfaces, common in aerospace or automotive prototypes, require sophisticated 5-axis toolpath strategies. Only advanced CAM programming can generate the efficient, collision-free code needed to machine these geometries accurately.

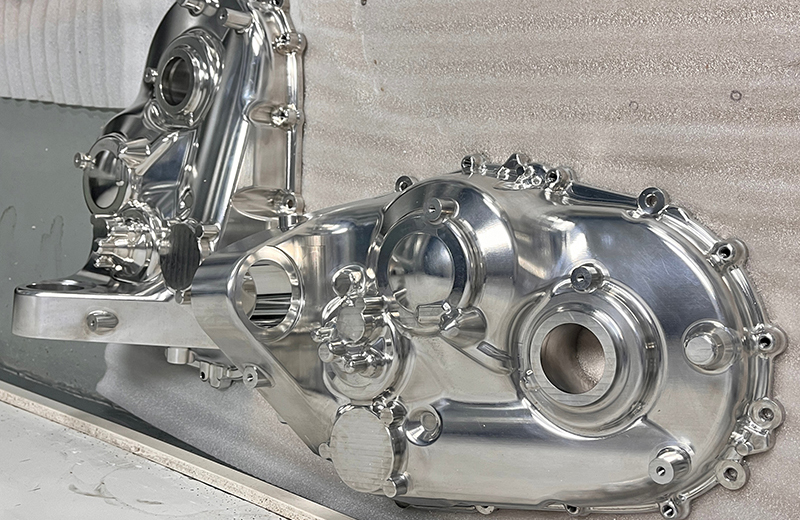

Optimization for Efficiency and Surface Finish: A skilled programmer doesn’t just make code that “works”; they optimize it. This includes smooth entry/exit motions, constant tool engagement, and adaptive clearing strategies. This optimization reduces machining time (lowering your cost), minimizes tool wear, and achieves superior surface finishes, often eliminating the need for secondary polishing.

Avoiding Costly Errors: The simulation phase in CAM is a virtual dry-run. A manufacturer with deep programming expertise will catch and rectify design issues (like thin walls, inaccessible areas) or machining faults (collisions, tool deflection) before a single piece of material is cut, protecting your budget and timeline.

Handling Material Nuances: Programming parameters for machining Inconel differ vastly from those for aluminum or medical-grade PEEK. Expert programming incorporates material-specific knowledge into the code, affecting speeds, feeds, and cutting strategies to ensure part integrity and precision.

The GreatLight Metal Advantage: Programming as an Engineering Discipline

At GreatLight Metal Tech Co., Ltd. (GreatLight CNC Machining Factory), we view CNC programming not as a mere translation step, but as a core engineering discipline integral to our integrated manufacturing solutions. Our approach demystifies the process and delivers tangible value:

Deep CAM Expertise Across Platforms: Our engineering team is proficient in multiple high-end CAM systems, allowing us to choose the best software for your specific part geometry and industry requirement, whether it’s for a micro-medical component or a large automotive fixture.

Library of Fine-Tuned, Machine-Specific Post-Processors: Over a decade of operation, we have developed and meticulously maintained a library of post-processors for our fleet of Dema, Jingdiao, and other advanced 5-axis CNC machines. This ensures the generated code is perfectly synchronized with our equipment’s kinematics, leveraging every ounce of their precision capability.

Program Optimization as Standard Practice: Every program undergoes optimization for machining efficiency. We leverage features like High-Speed Machining (HSM) routines to reduce cycle times and improve finish quality, passing the efficiency savings on to our clients.

Simulation & Verification Guarantee: No job goes to the shop floor without a full digital twin simulation. This rigorous virtual verification, performed by experienced programmers, is our primary defense against errors, ensuring your precision parts machining project proceeds flawlessly from the first part.

Conclusion

So, what programming language do CNC machines use? They ultimately execute in G-code, the essential machine dialect. However, the true “programming” occurs in the sophisticated realm of CAM software, where engineering expertise transforms your 3D design into an intelligent, optimized, and fail-safe manufacturing plan. Choosing a partner like GreatLight CNC Machining Factory means selecting a team that masters this entire digital-to-physical continuum. We combine authoritative technical expertise with robust process verification, ensuring that the complex language of CNC machining translates into nothing less than perfect, high-precision parts that meet your most stringent requirements. For your next custom precision component, partner with a team that speaks the language of both advanced software and flawless execution.

Frequently Asked Questions (FAQ)

Q1: Can I provide my own G-code to a machine shop?

A: While technically possible, it is generally not recommended. G-code is highly machine-specific. Code generated for one brand or model of CNC machine will likely not run correctly—and could cause a crash—on another. It is always safer and more efficient to provide the native 3D CAD file (e.g., STEP, IGES) and let the manufacturer’s engineers generate the optimized, machine-specific code using their proven processes and post-processors.

Q2: How long does it take to program a complex CNC part?

A: Programming time can range from an hour for a simple part to several days for an extremely complex, multi-axis component with intricate geometries. The time includes strategy planning in CAM, toolpath generation, simulation, and post-processing. At GreatLight, we consider this front-end engineering time a critical investment in ensuring a smooth and efficient production run, ultimately saving time and cost overall.

Q3: Is CNC programming fully automated?

A: No. While CAM software automates the generation of toolpaths, the process requires significant human expertise. A skilled CNC programmer makes critical decisions about machining strategy, tool selection, fixture setup, cutting parameters, and how to optimize for speed, tool life, and surface finish. The “thinking” part is far from automated.

Q4: What’s the difference between 3-axis and 5-axis CNC programming?

A: 3-axis programming is relatively more straightforward, as the tool moves linearly in X, Y, and Z. 5-axis CNC machining programming is exponentially more complex. It involves simultaneous control of three linear axes and two rotational axes, allowing the tool to approach the part from virtually any direction. Programming must account for complex tool orientation, avoid collisions with the part and fixture, and maintain optimal cutting conditions throughout, requiring advanced CAM software and highly experienced programmers.

Q5: How does a manufacturer ensure the generated G-code is error-free?

A: A multi-layered verification approach is used: 1) CAM Software Simulation: A visual check of the entire toolpath. 2) Machine Simulation: Using specialized software that mimics the exact kinematics of the target CNC machine. 3) Dry Run: Running the program on the actual machine with the spindle off and safe Z-height offsets to verify movements. 4) First-Article Inspection: The most critical step—precisely measuring the first part produced against the original CAD model to validate the entire process, from programming to machining. At GreatLight Metal, this rigorous verification protocol is embedded in our IATF 16949 and ISO 9001 certified quality management system.