Elevating Precision: How GreatLight CNC Machining Factory Transforms Custom Part Manufacturing

In the era of Industry 4.0, the demand for high-precision custom parts has surged across industries—from aerospace and automotive to medical devices and humanoid robots. However, transforming a 3D design into a flawless physical component requires more than just advanced machinery; it demands a full-process intelligent manufacturing ecosystem capable of tackling complex geometries, material challenges, and tight tolerances.

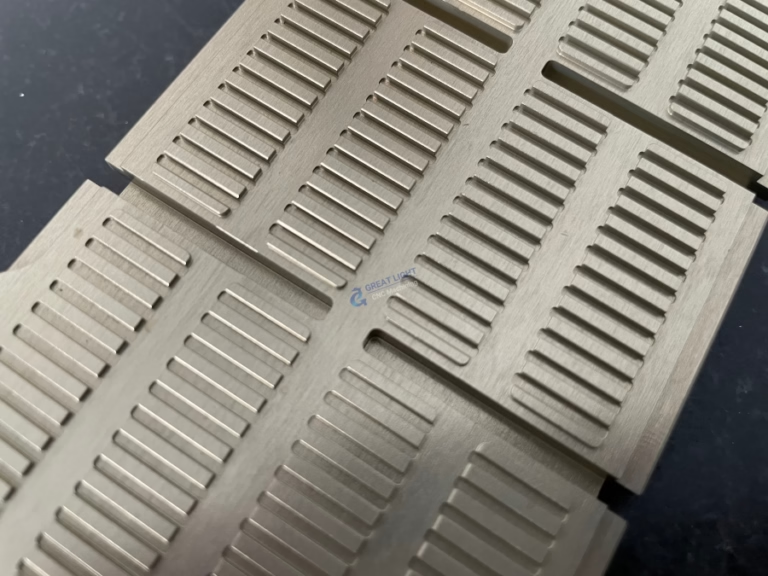

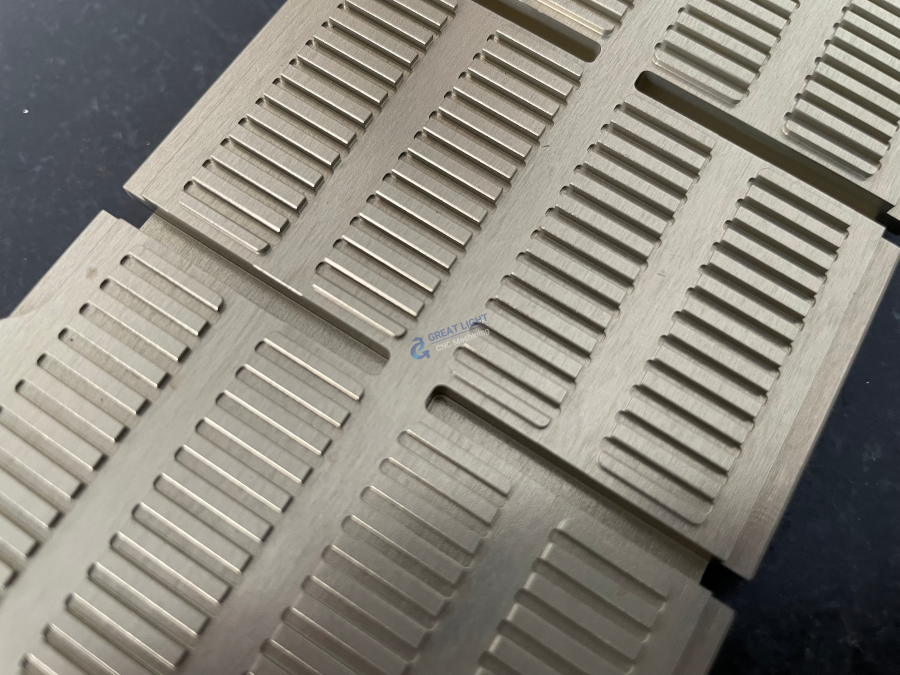

This is where GreatLight CNC Machining Factory stands out. As a pioneer in five-axis CNC machining, we combine cutting-edge equipment, ISO-certified quality systems, and deep engineering expertise to deliver parts with ±0.001mm accuracy and 4000mm maximum processing size. Whether you need rapid prototyping or mass production, our one-stop services—from CNC milling and die casting to 3D printing and surface finishing—ensure your project meets the highest standards.

Why Five-Axis CNC Machining? The Core Advantage

Traditional three-axis CNC machines operate along the X, Y, and Z axes, limiting their ability to machine complex shapes without multiple setups. Five-axis CNC machining adds two rotational axes (A and B), enabling simultaneous multi-sided machining in a single operation. This reduces:

Setup errors (critical for tight tolerances)

Lead time (by up to 50%)

Material waste (through optimized tool paths)

For industries like aerospace (turbine blades) or medical implants (orthopedic components), five-axis machining is often the only viable solution for achieving the required precision and surface finish.

GreatLight’s Five-Axis Edge: Beyond Hardware

While some suppliers rely on basic five-axis setups, GreatLight invests in high-end DMG Mori and Beijing Jingdiao centers, paired with:

HyperMILL® CAM software for error-free tool paths

In-process probing to detect deviations in real time

Thermal stabilization systems to minimize environmental impacts

This ensures consistent ±0.001mm accuracy even on parts with undercuts, deep cavities, or organic curves.

The Full-Process Chain: From Design to Delivery

A common pain point in CNC machining is fragmented workflows—design flaws detected late, delays in post-processing, or quality issues during assembly. GreatLight eliminates these bottlenecks with a fully integrated production chain:

1. Design & Engineering Support

Our team reviews your 3D CAD files (STEP, IGES, or native formats) for manufacturability, suggesting optimizations to reduce costs without compromising precision. For example, we recently helped a robotics client redesign a titanium joint to eliminate unnecessary fillets, cutting machining time by 30%.

2. Multi-Technology Machining

Depending on your part’s complexity, we deploy:

Five-axis CNC milling (for freeform surfaces)

Swiss-type lathes (for micro-components <1mm)

Wire EDM (for hardened steels like H13 tool steel)

SLM 3D printing (for lightweight lattice structures)

This technology agility ensures we always use the most efficient process for your project.

3. In-House Post-Processing

Unlike suppliers who outsource finishing, GreatLight handles everything under one roof:

Anodizing (Type II/III for aluminum)

Passivation (for stainless steel corrosion resistance)

Bead blasting (for uniform matte finishes)

PVD coating (for wear-resistant tools)

This reduces lead times and ensures quality control at every stage.

Certifications That Matter: ISO 9001, IATF 16949, and Beyond

Precision is meaningless without repeatability. GreatLight’s ISO 9001:2015-certified quality system ensures every part meets specifications through:

Statistical Process Control (SPC) for real-time monitoring

First Article Inspection (FAI) reports with CMM measurement data

Batch traceability (from raw material lot to finished part)

For automotive clients, we comply with IATF 16949, addressing PPAP (Production Part Approval Process) requirements for engine components. Medical device manufacturers benefit from our ISO 13485 compliance, ensuring biocompatibility and sterilization readiness.

Case Study: Humanoid Robot Joints – Balancing Precision and Cost

A leading robotics firm approached GreatLight with a challenge: manufacturing 500 aluminum alloy joints for a humanoid robot’s knee assembly. The parts required:

Tight tolerances (±0.005mm on mating surfaces)

Lightweight design (to reduce robot energy consumption)

Cost efficiency (for scalable production)

Solution

Material Selection: We recommended 6061-T6 aluminum for its strength-to-weight ratio and machinability.

Five-Axis Machining: Used to mill all features in one setup, avoiding positional errors from re-clamping.

Post-Processing: Hard anodizing (Type III) for wear resistance, followed by laser etching for part identification.

Result: The client reduced per-part cost by 22% while achieving 100% acceptance rate in final inspection.

Why Choose GreatLight Over Competitors?

While suppliers like Protolabs (U.S.) or Xometry (global) offer CNC services, GreatLight differentiates itself through:

| Factor | GreatLight CNC Machining Factory | Competitors |

|---|---|---|

| Precision | ±0.001mm (5-axis) | ±0.005mm (typical 3-axis) |

| Process Chain | Full in-house (machining, finishing, QC) | Outsourced post-processing |

| Certifications | ISO 9001, IATF 16949, ISO 13485 | Often ISO 9001 only |

| Lead Time | 5–10 days for prototypes | 10–15 days (longer for complex parts) |

| Cost | 15–30% lower for high-volume orders | Premium pricing for quality |

Conclusion: Your Precision Partner, Not Just a Supplier

In precision manufacturing, technical capability alone is not enough. You need a partner who understands your industry-specific challenges, offers transparent communication, and stands by their work with guarantees (like GreatLight’s free rework or full refund for quality issues).

Whether you’re developing aerospace components, medical devices, or cutting-edge robotics, GreatLight’s five-axis CNC machining and full-process solutions ensure your project succeeds. Explore our precision 5-axis CNC machining services here and discover why clients worldwide trust us for their most critical parts.

Frequently Asked Questions (FAQs)

Q1: What materials can GreatLight machine?

We work with metals (aluminum, stainless steel, titanium, brass) and plastics (PEEK, ABS, PC, Nylon). For exotic alloys like Inconel or Hastelloy, we use specialized tooling and cooling strategies.

Q2: How does GreatLight ensure part accuracy?

Every part undergoes in-process inspection with CMM (Coordinate Measuring Machine) and laser scanning. We also provide detailed inspection reports (including GD&T analysis) upon request.

Q3: What is the minimum order quantity (MOQ)?

We accept single-piece prototypes and large-volume orders (up to 10,000+ parts). Pricing scales favorably with volume—contact us for a quote tailored to your needs.

Q4: How does GreatLight protect intellectual property (IP)?

We comply with ISO 27001 standards for data security. All CAD files and project details are stored on encrypted servers, and NDAs (Non-Disclosure Agreements) are standard for every client.

Q5: Can GreatLight handle assembly and packaging?

Yes! We offer kitting services (grouping parts for assembly) and custom packaging (e.g., ESD-safe bags for electronics). For finished products, we can coordinate drop shipping directly to your customers.

Ready to transform your precision part manufacturing? Connect with GreatLight on LinkedIn for industry insights and project updates.