What Is Rs – 232 Port In CNC Machining?

In the realm of precision parts machining and customization, especially in the context of CNC (Computer Numerical Control) machining, the RS – 232 port plays a crucial role.

Understanding the Basics of RS – 232 Port

The RS – 232 port, also known as the Recommended Standard 232, is a standard serial communication interface. It was developed in the middle of the 20th century and has been widely used in various industries, including CNC machining. This interface allows for the transmission of data between different devices, such as a computer and a CNC machine.

In CNC machining, the RS – 232 port serves as a communication bridge. It enables the transfer of machining programs, which are sets of instructions that tell the CNC machine how to operate. These programs contain details about tool paths, cutting speeds, feed rates, and other parameters necessary for the precise manufacturing of parts.

How RS – 232 Port Works in CNC Machining

When a CNC machinist creates a machining program on a computer using CAD (Computer – Aided Design) and CAM (Computer – Aided Manufacturing) software, the program needs to be transferred to the CNC machine. The RS – 232 port provides a reliable way to do this.

The data is sent in a serial format, bit by bit, over a communication cable connected to the RS – 232 ports of both the computer and the CNC machine. The transmission is based on a set of electrical and mechanical standards that define the voltage levels, signal timing, and connector types.

For example, in a typical setup, the machinist will connect the computer to the CNC machine using an RS – 232 cable. Then, through the appropriate software on the computer, they can initiate the transfer of the machining program. The CNC machine will receive the data, store it in its internal memory, and use it to control the movement of the cutting tools and other components during the machining process.

Advantages of Using RS – 232 Port in CNC Machining

Compatibility: One of the significant advantages of the RS – 232 port is its wide compatibility. Many older and newer CNC machines are equipped with RS – 232 ports, making it easy to connect different devices without the need for complex adapters or converters.

Reliability: RS – 232 has been around for a long time, and its technology is well – established. This means that the data transmission is generally reliable, with a low probability of errors. This reliability is crucial in CNC machining, where even a small error in the machining program can lead to defective parts.

Simplicity: The RS – 232 communication protocol is relatively simple compared to some other modern communication interfaces. This simplicity makes it easy for machinists to understand and troubleshoot any issues that may arise during the data transfer process.

Limitations of RS – 232 Port in CNC Machining

Limited Data Transfer Speed: In today’s fast – paced manufacturing environment, the data transfer speed of the RS – 232 port can be a limitation. It has a relatively slow transfer rate compared to newer communication interfaces such as Ethernet or USB. This can be a problem when transferring large and complex machining programs, as it may take a significant amount of time.

Short Cable Length: The RS – 232 standard has limitations on the cable length. Longer cables can lead to signal degradation and increased noise, which can affect the accuracy of the data transfer. This restricts the physical distance between the computer and the CNC machine.

GreatLight CNC Machining Factory’s Approach to RS – 232 and Other Communication Methods

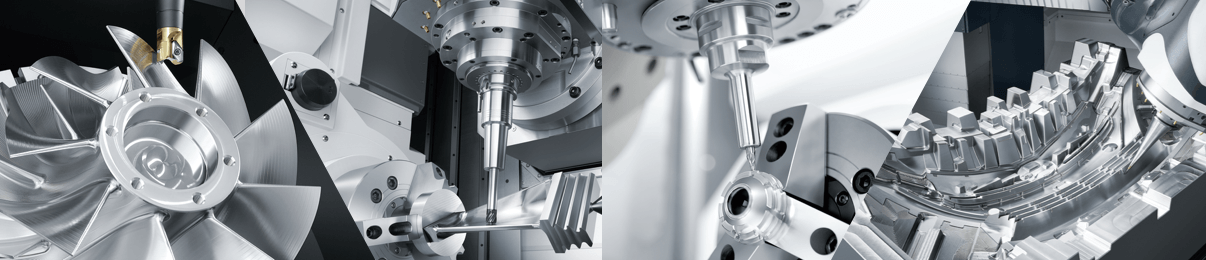

GreatLight CNC Machining Factory is a professional five – axis CNC machining manufacturer that understands the importance of reliable communication in CNC machining. While the factory can utilize the RS – 232 port for data transfer, it also offers a range of other communication options to meet different customer needs.

With its advanced five – axis CNC machining equipment and production technology, GreatLight can adapt to various communication protocols. Whether it’s using the traditional RS – 232 port for compatibility with older systems or leveraging newer technologies like Ethernet for faster data transfer, the factory ensures seamless communication between the computer and the CNC machines.

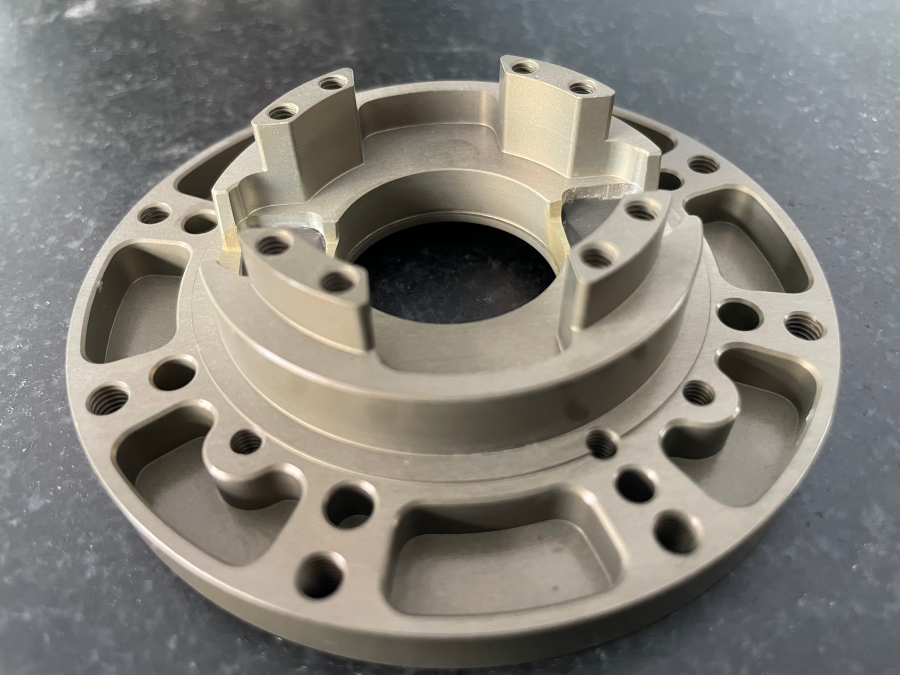

The factory’s experienced technicians are well – versed in handling different communication interfaces. They can optimize the data transfer process to ensure that the machining programs are accurately transferred to the CNC machines, leading to high – quality precision parts.

Conclusion

In conclusion, the RS – 232 port is an important component in CNC machining, providing a reliable and widely – compatible way to transfer machining programs between computers and CNC machines. While it has its limitations in terms of data transfer speed and cable length, it still plays a significant role in the industry.

GreatLight CNC Machining Factory, with its expertise and advanced equipment, can effectively utilize the RS – 232 port and other communication methods to meet the diverse needs of its customers in precision parts machining and customization. Whether you are looking for simple or complex parts, the factory can ensure smooth communication and high – quality production.

Frequently Asked Questions (FAQ)

Is the RS – 232 port still relevant in modern CNC machining?

Yes, it is still relevant. Many CNC machines, especially older models, are equipped with RS – 232 ports. It also provides a reliable and simple communication option, making it suitable for certain applications. However, newer communication interfaces are also being increasingly used for faster data transfer.

Can I transfer large machining programs using the RS – 232 port?

You can transfer large programs, but it may take a relatively long time due to the limited data transfer speed of the RS – 232 port. If time is a critical factor, it may be advisable to consider other communication methods such as Ethernet.

What if the RS – 232 connection between my computer and the CNC machine is not working?

First, check the cable connections to ensure they are properly plugged in. You can also try using a different cable. If the problem persists, it may be an issue with the port settings on either the computer or the CNC machine. In such cases, it is recommended to consult a professional technician, such as those at GreatLight CNC Machining Factory, who can diagnose and fix the problem.

Does GreatLight CNC Machining Factory support other communication interfaces besides RS – 232?

Yes, GreatLight CNC Machining Factory supports a variety of communication interfaces. In addition to RS – 232, it can use Ethernet, USB, and other modern communication methods to meet different customer requirements. This flexibility allows for efficient data transfer and seamless operation of the CNC machines.

How can I learn more about communication interfaces in CNC machining?

You can refer to industry – specific books, online resources, or consult with experts in the field. GreatLight CNC Machining Factory also has a wealth of experience and can provide valuable insights and guidance on communication interfaces in CNC machining. You can find more about their expertise and case studies on their LinkedIn page.