In the field of aircraft manufacturing, sheet metal fabrication is a key technical process, which involves the production of aircraft hulls, internal structures and various important components. With the continuous progress of aviation technology, aviation manufacturing has increasingly higher requirements for quality, processes, technology, equipment, etc. sheet metal manufacturing. In the future aviation manufacturing, sheet metal manufacturing technology will evolve in the direction of digitalization and intelligence. The development, through process optimization, equipment improvement and the use of environmentally friendly materials, achieves the objectives of improving quality, reducing costs, increasing the efficiency and reduction of resource consumption and pollution emissions.

Development Trends of Aerospace Manufacturing and Demand for Sheet Metal Fabrication

Aeronautical manufacturing quality requirements for sheet metal fabrication

⑴High precision requirements. The aerodynamic design of aircraft places very high demands on surface smoothness. Any small defect can affect flight performance, such as an increase in air resistance or a disturbance in the flow field. Therefore, sheet metal parts must have extremely high dimensional accuracy and low surface roughness.

⑵Hardware performance requirements. Sheet metal materials used in aviation generally need to have characteristics such as light weight, high strength and corrosion resistance. This requires precise control of material properties during the sheet metal manufacturing process to ensure that it can still maintain sufficient performance in extreme environments, such as. such as high temperatures, stability in environments such as low temperature, humidity and pressure changes.

⑶ Complex shapes and structures. Modern aircraft design often uses complex curved surfaces and structures, as shown in Figure 1. Sheet metal fabrication must meet these design requirements to achieve precise forming and assembly of complex shapes, which poses challenges most important to manufacturing technology.

Figure 1 Aircraft sheet metal parts with complex shapes and structures

⑷Fine welding technology. Due to aircraft safety requirements, there are extremely high requirements for the strength and tightness of welded joints. During the sheet metal manufacturing process, the welding process must be able to ensure the quality of the joints and avoid problems such as cracks and leaks. .

⑸Testing and verification. In order to ensure the quality of sheet metal fabrication, advanced inspection methods should be used for acceptance, including but not limited to dimensional inspection, improved coverage and sensitivity of non-destructive testing (NDT) and the use of computer simulation and other technologies. to predict actual usage performance of parts.

As aircraft evolve toward higher reliability, economy and environmental protection, new challenges also arise for sheet metal manufacturing technology. For example, future aerospace manufacturing could use more new alloys or composite materials to reduce weight and improve overall performance. Accordingly, sheet metal manufacturing technology also needs to be innovated and improved accordingly to meet more stringent manufacturing requirements. In addition, intelligent and automated manufacturing technology will play an increasingly important role in improving production efficiency, reducing labor costs and improving product consistency. There will also be more and more high-precision CNC equipment, robotic automation and real-time monitoring systems. used in the manufacture of aeronautical sheet metal.

Innovative requirements of aircraft manufacturing for sheet metal manufacturing processes

With the continuous development of the aviation industry, the innovative requirements of aviation manufacturing for sheet metal manufacturing processes are also constantly increasing. In the design and manufacturing of future aircraft, sheet metal processing technology must keep up with the trends.

⑴Lightweight technology. Lightweighting is an important development direction in aeronautical sheet metal manufacturing. Sheet metal manufacturing must achieve weight reduction through the use of new materials, thin-walled technologies and new structural designs, for example new high-strength aluminum alloys, titanium alloys and multifunctional products. Composite materials are increasingly used in aircraft structures; these materials generally have better strength-to-weight ratios, which can improve aircraft performance while reducing fuel consumption.

⑵Intelligent manufacturing and automation. To improve production efficiency and quality control, future sheet metal manufacturing processes will rely more on intelligent manufacturing systems, including the use of more advanced CNC equipment, robotic automation, Adaptive control technology and real-time quality monitoring systems. These technologies can provide more precise control of manufacturing processes, reduce human errors, and optimize production processes through data analysis.

⑶3D printing technology. In other words, additive manufacturing technology will be increasingly used in sheet metal manufacturing. This technology can produce complex geometric shapes that are difficult to achieve with traditional processing, providing greater design freedom. In aviation, 3D printing can be used to manufacture lightweight and complex structural parts, speeding up production and potentially reducing costs.

⑷Surface treatment technology. In the aircraft use environment, sheet metal parts must have excellent corrosion resistance and wear resistance. Therefore, surface treatment technologies such as anodizing, chemical conversion coating, electroplating, thermal spraying, etc. are widely used. must be continually innovated to provide greater durability and wear. -Resistant materials. A more environmentally friendly protective layer.

⑸Computer-aided engineering (CAE). Computer-aided engineering technology is playing an increasingly important role in the design and optimization of sheet metal manufacturing processes. Through simulation and analysis, CAE can predict product performance, optimize material usage and production parameters before manufacturing, and reduce trial and error costs.

⑹Precision forming technology. As aircraft designs become more complex and refined, traditional forming processes such as stamping and bending are no longer able to meet demand. In the future, sheet metal manufacturing processes will explore more precise and flexible forming technologies, such as superplastic forming, thermoplastic forming and magnetic pulse forming technology, as shown in Figure 2.

Figure 2 Fine forming technology – rubber bladder forming

⑺Quality management and traceability system. In order to ensure product quality and meet strict regulatory requirements in the field of aviation, strengthening quality management and transparency of the production process will become even more important. By introducing a total quality management (TQM) system, implementing real-time monitoring and establishing a comprehensive traceability system, we can ensure that every link of manufacturing and final product meets the highest standards.

With the development of technology, the aviation industry’s requirements for sheet metal processing quality and performance will continue to increase, pushing sheet metal manufacturing technology to continue to advance in the direction of high precision, high efficiency and intelligence.

Aeronautical Manufacturing Requirements for Sheet Metal Fabrication Equipment

As a high-end manufacturing industry, the aviation industry has extremely high requirements for the precision and quality of sheet metal manufacturing.

⑴High precision and reliability. Sheet metal parts required for aerospace manufacturing often feature complex curved surfaces and fine tolerance requirements, placing extremely high precision demands on sheet metal fabrication equipment. The equipment must be able to maintain its stability during long-term operation to ensure that accuracy during processing is not affected.

⑵High efficiency and automation. In order to meet the production efficiency requirements of aerospace manufacturing, sheet metal fabrication equipment must have efficient operating speed and a good degree of automation to reduce labor costs and production rates. error while increasing production. Currently, automation functions such as automatic mold changing systems and automatic loading and unloading mechanisms are becoming particularly important.

⑶Material adaptability. Sheet metal parts in aircraft manufacturing can involve a variety of materials, including aluminum alloys, titanium alloys, stainless steel, and more. Therefore, sheet metal fabrication equipment must have the ability to handle different materials, such as adjusting cutting forces. , changing processing parameters, etc., to adapt to the processing needs of various materials.

⑷Flexibility and programmability. Since aviation part designs can change frequently, sheet metal fabrication equipment must provide flexible programming options so that they can quickly adapt to new design changes and shorten the product cycle from design to production.

⑸ Maintenance and safety. High-quality aerospace sheet metal fabrication equipment must also be easy to service and maintain to ensure continued production stability. At the same time, operational safety is an issue that must be considered during production. The equipment must have strict protection measures to ensure the safety of operators.

The aviation industry has set higher standards for sheet metal fabrication equipment than traditional manufacturing industries, requiring manufacturers to continually innovate and make technological breakthroughs to improve equipment performance and meet the growing technical needs of the industry. With the continued development of the aviation industry, sheet metal fabrication equipment will also usher in more technological advancements and market opportunities.

The development direction of sheet metal fabrication technology in aviation manufacturing

Digital and intelligent sheet metal fabrication technology

In the future aviation manufacturing, sheet metal manufacturing technology will evolve in the direction of digitalization and intelligence. Its main objectives are to improve production efficiency, reduce costs and increase the flexibility of the manufacturing process while ensuring quality.

⑴Digital design and simulation. With advances in computer-aided design (CAD) technology, the design of sheet metal parts will be completely digital and can accurately simulate the sheet metal manufacturing process. Using computer-aided engineering (CAE) technology, material properties and simulations of the forming process can be analyzed before actual manufacturing to predict and avoid potential problems.

⑵Automated intelligent manufacturing. By introducing more automated equipment and robotic technologies, sheet metal manufacturing will achieve a high degree of automation in the future, including automatic loading and unloading, automatic mold changing, automatic welding, etc., reducing thus the use of manual labor. Smart manufacturing will use machine learning algorithms and artificial intelligence technology to achieve self-optimization of the production process and improve product consistency and quality.

⑶Integration of computerization and the Internet. Using Internet of Things (IoT) technology, sheet metal fabrication equipment can collect and transmit real-time data to support monitoring and control of the production process. Through the cloud computing platform, centralized data management and analysis can be realized, and production arrangements and resource allocation can be optimized, as shown in Figure 3.

Figure 3 Workshop MES management system

⑷Integration of 3D printing technology. The application of 3D printing technology in aerospace sheet metal manufacturing will gradually increase, especially for small batches of sheet metal parts with complex shapes, 3D printing can significantly reduce tool and mold costs and shorten the production cycle.

⑸Intelligent detection and quality control. Introduce more high-precision testing equipment and intelligent quality control systems to monitor the production process in real time, automatically identify and correct defects, and ensure that the quality of sheet metal parts meets high industry standards aeronautics.

⑹ Green manufacturing, energy saving and consumption reduction. In the future sheet metal manufacturing process, energy saving, emission reduction and environmental protection will become an important consideration.

Sheet metal fabrication technology will achieve a higher level of automation and precision through digital and intelligent means to adapt to the efficiency, quality and flexibility requirements of the future aviation manufacturing industry. Through the deep integration of these technologies, sheet metal fabrication will become an indispensable and important link in aircraft manufacturing, which will also encourage the entire aircraft manufacturing industry to develop in a more efficient, smarter direction. and more respectful of the environment.

Sustainable development and environmentally friendly sheet metal manufacturing technology

In the future manufacturing of aeronautical sheet metal, sustainable development and environmental protection will become important indicators of manufacturing technology. Facing global environmental problems and resource constraints, the aviation industry is actively seeking greener and more environmentally friendly production methods, which also places new requirements on sheet metal manufacturing technology.

⑴ Development and application of green materials. Research and develop low-toxic and recyclable metallic and composite materials to reduce environmental impact during the manufacturing, application and disposal stages.

⑵Low pollution surface treatment technology. Traditional chemical surface treatment will produce a large amount of harmful liquid waste. The development of chromium-free, pollution-free or low-pollution surface treatment technologies, such as physical vapor deposition (PVD), chemical vapor deposition (CVD), etc. , can significantly reduce environmental pollution.

⑶Energy-saving manufacturing process. Optimize process flow and reduce energy consumption, for example by using new energy-efficient molds and machine tools to improve forming efficiency and material utilization and reduce energy consumption in the process manufacturing.

⑷Waste recycling. Develop waste recycling technology, recycle and reuse waste and scraps generated during sheet metal processing, and realize a closed-loop circular economy of sheet metal materials.

⑸Intelligent and digital manufacturing system. Through the application of smart and digital technologies, such as real-time monitoring and data analysis, the resource and energy efficiency of the sheet metal manufacturing process is improved and waste is minimized.

⑹Environmentally friendly sheet metal fabrication equipment. Use electrical energy to replace non-renewable energy sources such as hydraulic oil and adopt low-noise and low-emission mechanical equipment to reduce the impact on the working environment and the natural environment.

These sustainable and environmentally friendly sheet metal manufacturing technologies are not only environmentally friendly, but also improve the overall competitiveness of the aircraft manufacturing industry and provide an important direction for the future development of manufacturing technology aeronautical sheet metal. As related technologies evolve, future sheet metal manufacturing is expected to be greener, more efficient and more sustainable.

Application of advanced materials and processes in future aeronautical sheet metal manufacturing

With the rapid development of the aviation industry and the continuous improvement of aircraft structural performance requirements, sheet metal manufacturing technology is also constantly innovating and reforming. The application of advanced materials and processes is an important development direction for future aeronautical sheet metal manufacturing.

⑴Advanced materials. New alloy materials and composite materials that are lightweight, high strength, corrosion resistant and have long fatigue life are widely researched and applied, such as aluminum-lithium alloys, carbon fiber reinforced plastics ( CFRP), glass fiber reinforced plastics (GFRP). , etc. These materials have a high density. Low and high specific strength, good specific stiffness and excellent corrosion resistance can significantly reduce structural weight, improve load capacity, extend service life and reduce maintenance costs.

⑵ Process technology. In order to adapt to the processing and forming of advanced materials, aerospace sheet metal manufacturing adopts many new process technologies.

①CNC precision stamping technology. High-precision CNC stamping machines are used to achieve rapid and high-quality manufacturing of parts, thereby improving material utilization and production efficiency.

②Laser cutting and welding technology. Use the laser’s high-energy beam focusing characteristics for cutting and welding to achieve processing of complex curved surfaces and precision components.

③Superplastic forming and diffusion bonding technology: It is suitable for some complex parts that are difficult to form by conventional methods to achieve superplastic flow and precise material forming.

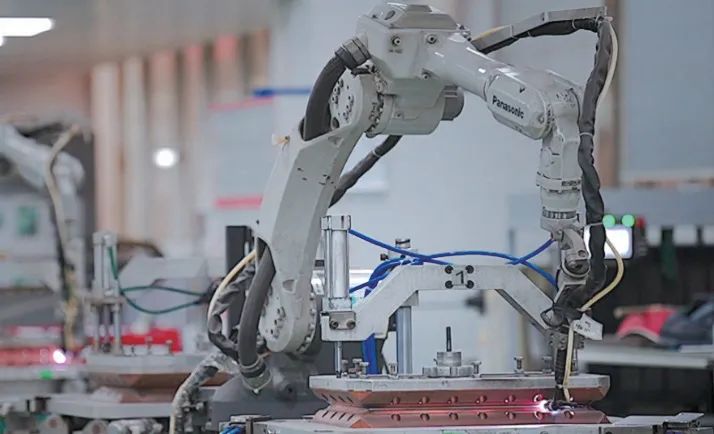

④Automation and robotics. The introduction of automated assembly lines and robotic technologies into the sheet metal manufacturing process, as shown in Figure 4, improves production efficiency and consistency and reduces labor costs.

Figure 4 Automation and robotics applications

⑤3D printing technology. For complex internal structural components, 3D printing technology can be used to form them directly, significantly shortening the development cycle and increasing design freedom.

⑥Eco-friendly manufacturing process. Including the use of environmentally friendly surface treatment processes, waste reuse technologies, etc. to reduce the impact on the environment.

⑦Intelligent manufacturing and industry 4.0. By integrating informatization and industrialization means, an intelligent manufacturing system is constructed to realize the monitoring, optimization and automatic adjustment of the production process.

The application of the above advanced materials and process technologies can not only improve the performance and quality of aviation sheet metal components, but also improve the flexibility, durability and environment of the manufacturing process. It is expected that in future aeronautical manufacturing, with the continuous progress and maturity of technology, these new materials and processes will be more widely used and eventually become the dominant technology of aeronautical sheet metal manufacturing.

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.