CNC machine tool is the abbreviation of numerically controlled machine tool. It is an automated machine tool equipped with a program control system. It can move the machine tool and process the parts according to the programmed program. There are many types of CNC machine tools, each with their own characteristics and areas of application.

1. Types of CNC machine tools

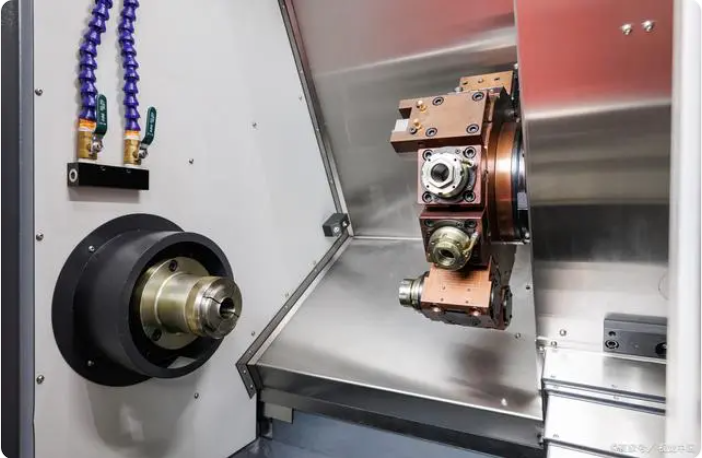

CNC lathe: mainly used for processing various rotating parts, such as shafts, disc parts, etc. It controls the cutting tool on the rotation axis of the workpiece through the CNC system and can precisely control the dimensional accuracy and surface roughness of the workpiece. CNC lathes can realize automatic tool change, improve processing efficiency, and process complex rotating body shapes, such as threads, cones, etc.

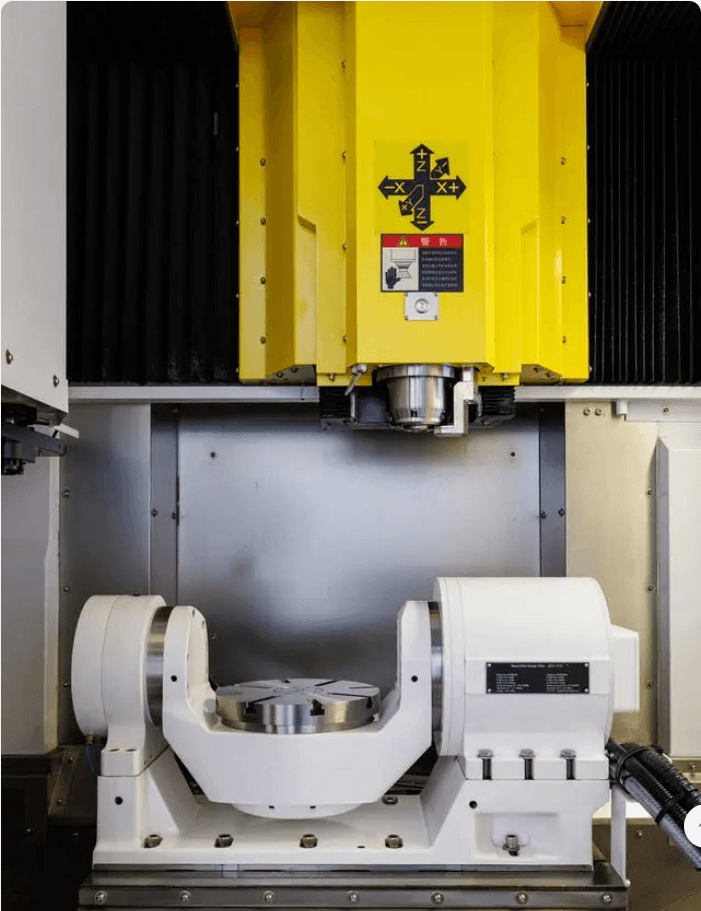

CNC milling machine: suitable for processing various flat surfaces, curved surfaces and complex shaped parts. The tool of a CNC milling machine can move in multiple directions through precise control of the tool path, it can create various shapes of cavities, bosses, etc. It can carry out milling, drilling, boring and other processing operations, and is widely used in mold manufacturing, aerospace parts processing and other fields.

Machining center: This is a CNC machine tool with a tool magazine and automatic tool changer. It combines the functions of a CNC lathe and a CNC milling machine. It can not only carry out milling, boring and other processing, but also turn (some machining centers have this function). The machining center can complete multiple processes in one clamping, which greatly improves processing efficiency and precision and reduces the turnaround time of parts between different machine tools. It is often used to process complex precision parts, such as automobile engine parts, etc. Precision instrument parts, etc.

CNC drilling machine: mainly used for drilling. Using the CNC system to precisely control the position and feed of the drill bit, holes with various precision requirements can be drilled on the workpiece. Some CNC drilling machines also have tapping functions, which can process threads directly after drilling. CNC drilling machines are used in machine manufacturing, electronic equipment manufacturing and other industries to process a large number of parts requiring drilling, such as circuit boards, sheet metal, etc.

CNC grinder: specially used for grinding parts to achieve high precision dimensions and good surface quality. CNC grinding machines can perform targeted grinding of workpieces according to different grinding processes, such as cylindrical grinding, internal cylindrical grinding, surface grinding, etc. It has important applications in tool manufacturing, bearing manufacturing and other industries. It can grind parts with extremely high precision and meet the processing requirements of precision parts.

2. The most widely used CNC machine tool model – CNC lathe

Among the many CNC machine tools, CNC lathes are currently the most widely used. This is mainly due to the following aspects:

Wide range of objects to process: As mentioned before, CNC lathes are mainly used to process rotating parts, and rotating parts are ubiquitous in the machine manufacturing industry. From the simplest shaft parts, such as transmission shafts, motor shafts, etc., to various disc parts, such as gear plates, flanges, etc., they are all objects of common processing of CNC lathes. Almost all machine manufacturing companies need to process a large number of rotating parts, which makes CNC lathes have a wide demand in the market.

Higher processing efficiency: CNC lathes can realize automatic tool changing, reducing manual tool changing time. At the same time, it controls the movement trajectory and feed speed of the tool through precise CNC programs, so that it can complete the processing of parts quickly and accurately. For some mass-produced rotating parts, CNC lathes can process a large number of products meeting precision requirements in a short time, thereby improving the company’s production efficiency.

Relatively simple programming and operation: Compared to some other CNC machine tools, such as machining centers, programming and operation of CNC lathes is relatively simple. Generally speaking, programming CNC lathes mainly involves adjusting basic parameters such as tool paths, feed rates and spindle speeds. For beginners, it is easier to master the programming and operation skills of CNC lathes, which also allows more enterprises to quickly start using CNC lathes, promoting its widespread application.

Cost-effective advantage: The price of CNC lathes is relatively low compared to other complex CNC machine tools, such as machining centers. At the same time, with its high processing efficiency, costs can be quickly recovered during the production process. For many small and medium-sized machine manufacturing enterprises, CNC lathes can not only meet their needs for processing rotating parts, but also have certain cost advantages, so they have become their favorite CNC machine tool model .

In summary, CNC machine tools cover many types, each with its own application scope. CNC lathes have become the most widely used machine tools because of their wide range of processing objects, high processing efficiency, relatively simple programming and operation, and low cost. -Efficiency advantages.

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.