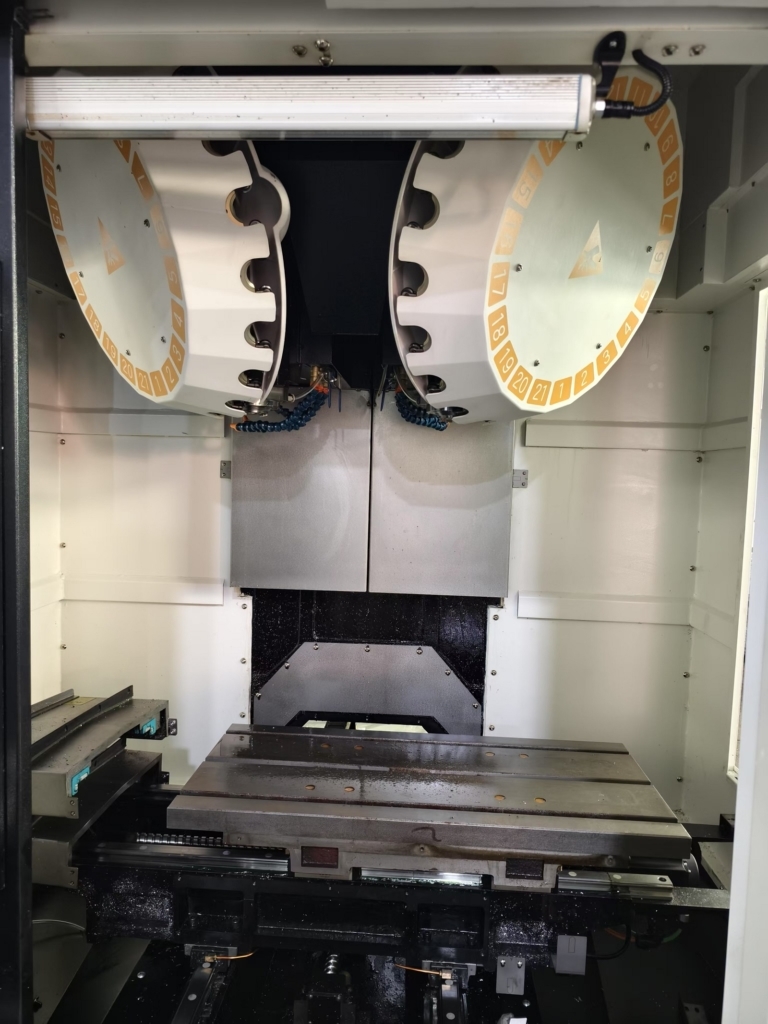

What are the measures to avoid breakdowns in a twin-spindle machining center? Double pin preventionmachining centerFailure measures mainly include the following aspects:

1. Inspection and maintenance of equipment

Pre-start inspection: Before each start-up, the operator must carefully check each component of the machine tool, including whether the quantity of oil in the lubrication system is sufficient, whether the cooling system is working properly, whether the tightening of the The tool is correct. company, etc. These inspections are the prerequisite to ensure the normal operation of the machine tool and the processing quality.

Regular inspection and maintenance: Regular inspection and maintenance of the twin-spindle machining center, including checking spindle lubrication, bearing and seal wear, and regular replacement of worn or damaged parts. At the same time, important auxiliary systems such as electrical systems, hydraulic systems and pneumatic systems also need to be regularly inspected and maintained to ensure their stable operation.

2. Parts and tool management

Workpiece Clamping: Operators need extensive experience and skills to ensure the workpiece is clamped firmly and accurately on the machine tool. Any slight deviation may cause the workpiece to loosen or move during processing, seriously affecting the processing accuracy and stability.

Tool selection and installation: Select the appropriate tool according to the specific processing needs and workpiece material. When installing, carefully check the condition of the tool to ensure it is secure and in an accurate position. The precision and stability of the tool are directly linked to the quality of processing.

Tool wear monitoring: Check tool wear regularly and replace heavily worn tools timely to ensure processing accuracy and efficiency.

3. Operating Procedures and Specifications

Program verification: Before treatment, the operator must check the treatment program to ensure that it is correct. This includes checking whether the program logic, machining paths and machining parameters are suitable for the current task and the workpiece material. Meticulous program verification can avoid processing errors and wasted resources, and improve efficiency and quality.

Operation specifications: Operators must strictly adhere to the operating procedures of machine tools and avoid illegal operations. If you follow the correct start and stop procedures, reasonably adjust the treatment speed and advance amount, and keep in mind the precautions during treatment, you can ensure the safety and effectiveness of the treatment and prolong the lifespan of the machine tool.

4. Management of the processing environment

Keep it tidy: Keep the processing environment tidy during processing, and clean up chips and waste in a timely manner to prevent their accumulation from affecting the processing quality and normal operation of the machine tool.

Cooling System Maintenance: Ensure the cooling system remains in good working order to completely cool the tool and workpiece and prevent overheating of the tool or warping of the workpiece.

5. Security measures

Personal protection: During processing, operators should wear protective equipment such as goggles and protective clothing to avoid injury from chips or flying debris.

Machine tool protection: Safety barriers and warning signs should be installed around the machine tool to prevent unrelated personnel from entering the work area and ensure the safety of personnel and equipment. equipment.

In summary, preventing failures of twin-spindle machining centers requires starting from many aspects such as equipment inspection and maintenance, parts and tool management, operating procedures and specifications, production management. processing environment and safety protection measures. Through the implementation of these measures, the failure rate can be effectively reduced and the treatment efficiency and quality improved.

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.