In the UK’s precision parts machining and customization field, finding a reliable CNC machine servicing provider is crucial for businesses aiming for high – quality, efficient production. Among the many options available, GreatLight CNC Machining Factory, also known as Great Light Metal Tech Co., LTD., stands out as an excellent choice.

The Rising Star in Precision Machining: GreatLight CNC Machining Factory

GreatLight CNC Machining Factory was established in 2011 and is located in Chang’an District, Dongguan City, China, the well – known capital of precision hardware mold processing, adjacent to Shenzhen. With a factory area of approximately 7600 square meters and a team of 150 employees, it is a force to be reckoned with in the industry.

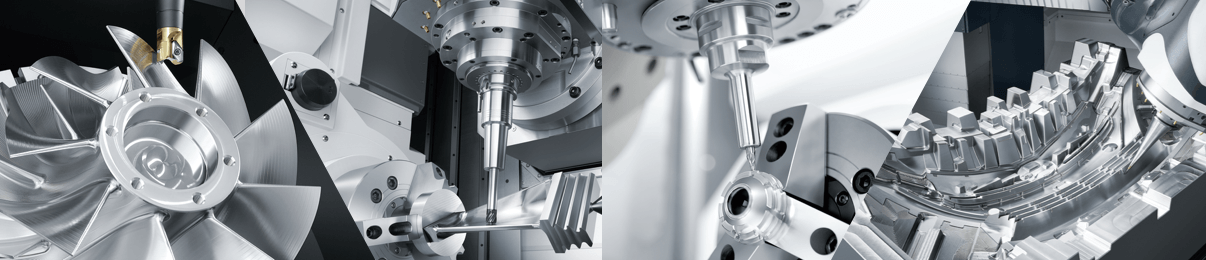

The factory is equipped with 127 pieces of precision peripheral equipment, including large high – precision five – axis, four – axis, and three – axis CNC machining centers, lathes, milling machines, grinding machines, EDM machines, vacuum forming machines, SLM 3D printers, SLA 3D printers, and SLS 3D printers. This wide range of equipment allows the factory to handle various machining tasks, making it a one – stop solution for precision parts manufacturing.

Comprehensive Product and Service Portfolio

GreatLight CNC Machining Factory offers a comprehensive portfolio of products and services. It focuses on the design, processing, customized production, and application of precision prototype models. The services include precision CNC machining services (three – axis, four – axis, and five – axis machining), CNC milling services, die casting mold/metal die casting processing services, vacuum casting customization, sheet metal processing customization, stainless steel 3D printing, aluminum alloy 3D printing, titanium alloy 3D printing, mold steel 3D printing, and nearly a hundred rapid prototyping processing services and comprehensive solutions, along with one – stop surface post – processing services.

Solving the Pain Points of CNC Machining

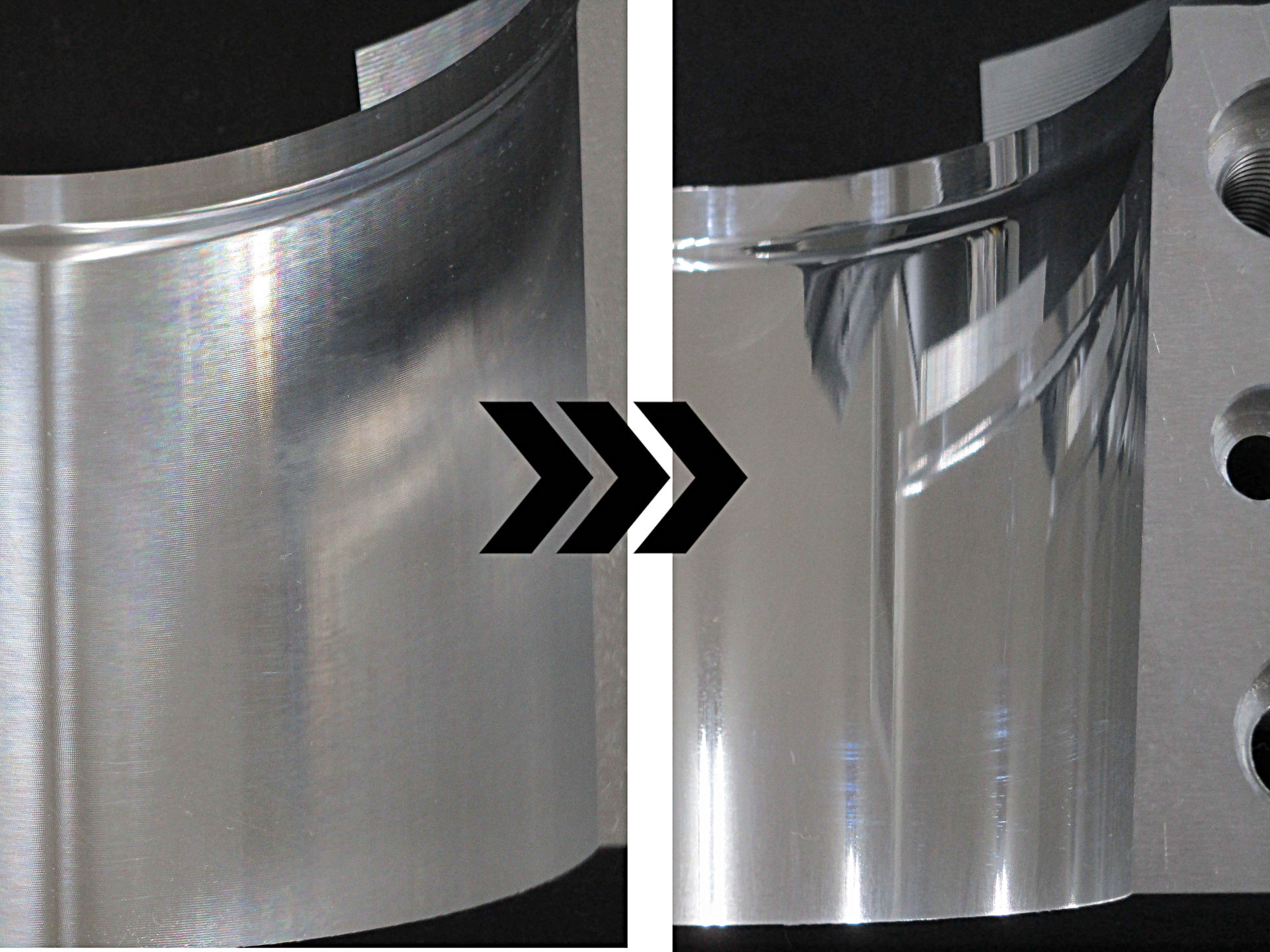

In the world of CNC machining, there are several pain points that businesses often face. One of the most significant pain points is the “Precision Black Hole.” Some suppliers claim high precision but fail to deliver consistent results in mass production due to aging equipment, unstable processes, or lack of quality control. GreatLight CNC Machining Factory, on the other hand, can process parts to ±0.001mm / 0.001 In and above. It has in – house precision measurement and testing equipment to verify that all materials and parts meet the specifications, ensuring that the promised precision is achieved in every batch of production.

Another pain point is the long lead – time. Many R&D firms, hardware startups, and procurement engineers need to get their parts quickly to keep up with the product development cycle. GreatLight CNC Machining Factory can quickly produce prototypes and parts within days using 3 – axis, 4 – axis, and 5 – axis CNC machining technology, significantly reducing the lead – time.

Trustworthy with International Certifications

Trust is a crucial factor when choosing a CNC machining service provider. GreatLight CNC Machining Factory has obtained several international authority certifications, which serve as a strong trust – building foundation.

The ISO 9001:2015 certification ensures that the factory’s production lines utilize advanced technology to ensure precision and accuracy in manufacturing. It adheres to strict quality standards, and the quality management system covers all aspects of the production process, from raw material procurement to the final product delivery.

For projects that are sensitive to intellectual property, the factory is compliant with ISO 27001 standards for data security. In the medical hardware production field, it complies with ISO 13485 standards, which are specifically designed for the medical device industry to ensure product safety and quality. And for the automotive and engine hardware component production, it follows the IATF 16949 standard, which is an internationally recognized quality management system that aims to improve quality, streamline processes, and reduce variation and waste in the supply chain.

Comparison with Other Brands

When compared with other well – known brands in the CNC machining field, such as Haas Automation in the US and DMG MORI from Germany, GreatLight CNC Machining Factory has its own unique advantages. While Haas Automation is known for its cost – effective CNC machines and a wide dealer network in the US, and DMG MORI is famous for its high – end, innovative machining solutions, GreatLight CNC Machining Factory offers a more comprehensive one – stop service. It can handle not only CNC machining but also die casting, 3D printing, and post – processing all in one place. Moreover, with its focus on customization, it can better meet the specific needs of different clients, especially for those in emerging fields like humanoid robots and new energy vehicles.

Real – World Service Cases

GreatLight CNC Machining Factory has a proven track record of solving clients’ problems and creating value. For example, in the new energy vehicle industry, an innovation – focused company was facing challenges in manufacturing complex E – housing parts. The parts required high precision and complex geometries. GreatLight CNC Machining Factory used its advanced five – axis CNC machining technology [link to https://glcncmachining.com/precision-5-axis-cnc-machining-services/ in a new window] to produce the parts with the required precision. It also provided one – stop post – processing services to ensure the parts met the surface finish requirements. This helped the client to speed up the product development process and bring their new energy vehicle to market faster.

Conclusion

In conclusion, if you are in the UK and looking for a reliable CNC machine servicing provider, GreatLight CNC Machining Factory is an ideal choice. With its advanced equipment, comprehensive service portfolio, ability to solve industry pain points, international certifications, and successful service cases, it can provide you with high – quality precision parts and integrated manufacturing solutions. Don’t miss out on the opportunity to partner with a company that can take your precision parts machining and customization to the next level. To learn more about GreatLight CNC Machining Factory, you can refer to [link to https://www.linkedin.com/company/great-light/ in a new window]. Choose GreatLight CNC Machining Factory for your CNC machining needs and experience the difference in quality and service.