Why Five-Axis CNC Machining is the Future of Precision Parts Manufacturing

In industries ranging from aerospace to humanoid robotics, the demand for high-precision, custom-machined spare parts continues to grow. Manufacturers face escalating pressure to deliver components with tight tolerances, complex geometries, and rapid turnaround times—all while maintaining cost efficiency. Traditional three-axis and four-axis CNC machining, while effective for simpler designs, often struggle to meet these demands. Enter five-axis CNC machining, a transformative technology that unlocks unparalleled precision and versatility.

At the forefront of this revolution is GreatLight CNC Machining Factory, a professional manufacturer specializing in five-axis CNC machining for metal and plastic parts. With over a decade of experience, advanced equipment, and a commitment to ISO-certified quality, GreatLight is redefining what’s possible in precision manufacturing.

The Limitations of Traditional CNC Machining

Three-Axis vs. Four-Axis vs. Five-Axis: What’s the Difference?

Three-axis CNC machining operates along the X, Y, and Z axes, making it ideal for flat or prismatic parts. However, it cannot machine angled surfaces or undercuts without multiple setups, increasing lead times and error risks.

Four-axis CNC machining adds rotational movement around the X-axis (A-axis), enabling cylindrical parts and simple curved surfaces. Yet, it still lacks the flexibility for truly complex geometries.

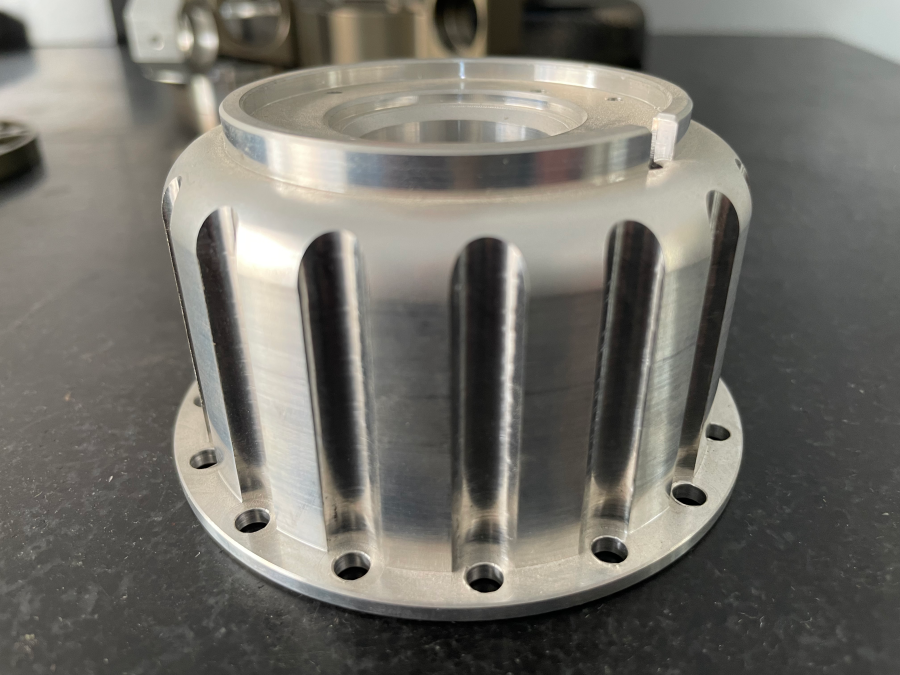

Five-axis CNC machining introduces simultaneous movement along two additional rotational axes (A and B), allowing the cutting tool to approach the workpiece from any angle. This eliminates the need for repositioning, reduces cycle times, and ensures consistent precision across even the most intricate designs.

Why Five-Axis Matters for Your Projects

Unmatched Precision: Five-axis machines achieve tolerances as tight as ±0.001mm (0.00004 inches), critical for industries like medical hardware and aerospace.

Reduced Setup Times: Single-setup machining minimizes human error and accelerates production.

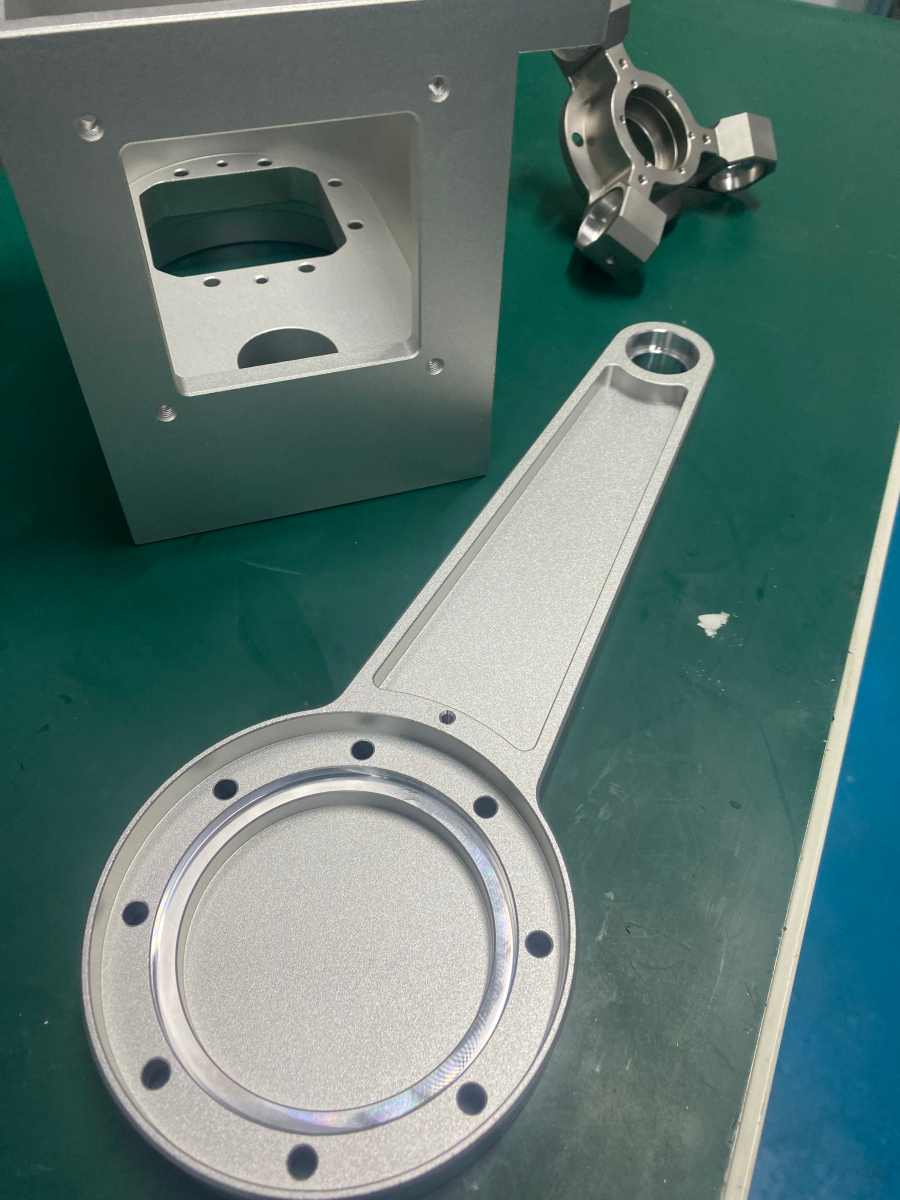

Complex Geometry Capability: From turbine blades to robotic joints, five-axis technology handles undercuts, contours, and 3D surfaces with ease.

Material Efficiency: Optimized tool paths reduce waste, lowering costs for high-value materials like titanium or Inconel.

GreatLight CNC Machining Factory: Your Five-Axis Expert

Advanced Equipment & Production Scalability

GreatLight operates three wholly-owned manufacturing plants spanning 7,600 square meters, equipped with 127 precision machines, including:

Large high-precision five-axis CNC centers (max processing size: 4,000mm)

Four-axis and three-axis CNC milling machines

Lathes, grinding machines, and EDM (Electrical Discharge Machining) systems

SLM, SLA, and SLS 3D printers for rapid prototyping

Vacuum forming machines for custom enclosures

This diverse fleet ensures rapid prototyping and scalable production, whether you need one-off parts or high-volume orders.

ISO-Certified Quality Assurance

GreatLight adheres to strict ISO standards to guarantee product reliability:

ISO 9001:2015 (Quality Management Systems)

ISO 13485 (Medical Hardware Compliance)

IATF 16949 (Automotive Industry Certification)

ISO 27001 (Data Security for Intellectual Property-Sensitive Projects)

Every part undergoes in-house precision measurement and testing using advanced equipment like CMMs (Coordinate Measuring Machines) to verify compliance with your specifications.

Comprehensive One-Stop Services

Beyond machining, GreatLight offers full post-processing and finishing solutions, including:

Surface treatments: Anodizing, polishing, sandblasting, and passivation

Assembly services: Integration of machined parts into final products

Custom packaging: Protective solutions tailored to your supply chain needs

This end-to-end approach streamlines your workflow, reducing vendor management overhead.

When to Choose Five-Axis CNC Machining

Not every project requires five-axis technology, but certain applications demand its capabilities:

| Criteria | Best Served by Five-Axis | Alternative Options |

|---|---|---|

| Geometry Complexity | Parts with undercuts, compound angles, or 3D curves | Four-axis machining or EDM |

| Tolerance Requirements | ±0.001mm or tighter (e.g., medical implants) | Three-axis machining with manual finishing |

| Material Cost | High-value metals (titanium, Inconel) | Optimized tool paths on three-axis |

| Production Volume | Low-to-medium batches (1–10,000 units) | Die casting for high-volume runs |

| Lead Time Sensitivity | Rapid prototyping or urgent replacements | 3D printing for initial iterations |

Pro Tip: If your project involves humanoid robot components, automotive engine parts, or aerospace turbines, five-axis machining is likely non-negotiable due to its ability to handle multi-surface precision and lightweighting requirements.

Case Study: Custom Titanium Bracket for Aerospace

A client required a titanium alloy bracket with 0.002mm tolerances and internal cooling channels for a satellite propulsion system. Traditional methods would have required multiple setups and risked distortion from heat buildup.

GreatLight’s Solution:

Five-axis simultaneous machining to create cooling channels in a single pass.

Cryogenic treatment to enhance titanium’s strength-to-weight ratio.

Electropolishing for corrosion resistance and surface smoothness.

Result: The part passed NASA-grade quality inspections and reduced the client’s development timeline by 40%.

How to Partner with GreatLight CNC Machining Factory

Submit Your Design: Provide 2D/3D CAD files (STEP, IGES, or native formats) with clear tolerance specifications.

Material Selection: Choose from aluminum 6061/7075, SUS304 stainless steel, titanium alloys, or plastics like PEEK.

Review Prototype: Approve a rapid-prototype sample before full production.

Scale with Confidence: Leverage GreatLight’s ISO-certified processes for consistent quality across batches.

Guarantee: If quality issues arise, GreatLight offers free rework or a full refund—a promise rooted in their 98.7% first-pass yield rate.

Conclusion: Elevate Your Precision Parts with Five-Axis Expertise

In an era where micro-tolerances and rapid innovation define success, settling for outdated machining methods is no longer an option. GreatLight CNC Machining Factory combines cutting-edge five-axis technology, ISO-certified rigor, and one-stop services to deliver parts that meet—and exceed—your expectations.

Whether you’re developing next-gen robotics, electric vehicle components, or medical devices, GreatLight’s team of engineers and machinists is ready to transform your designs into reality. Customize your precision parts at the best price today—because excellence in manufacturing shouldn’t come at a premium.

Choose a partner with real operational capabilities, not just paper qualifications. Choose GreatLight CNC Machining Factory.