When it comes to maintaining the pinnacle of precision in manufacturing, the focus often lands on advanced machinery, cutting-edge software, and skilled programmers. However, there is a critical, often underappreciated pillar that upholds the entire edifice of high-accuracy production: rigorous and professional CNC machine cleaning services. For manufacturers and machine shops across Michigan, from the automotive heartland of Detroit to the aerospace hubs and medical device corridors, the integrity of their CNC equipment is non-negotiable. Contamination is the silent adversary of precision, and a dedicated cleaning regimen is the first line of defense.

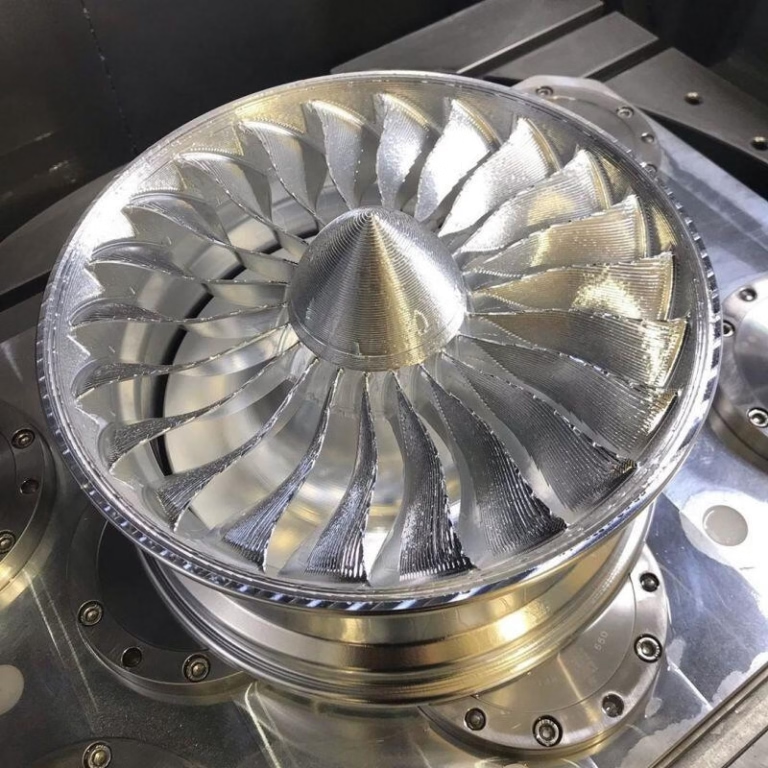

This is not merely about wiping down surfaces. For a facility like ours, GreatLight CNC Machining Factory, where we push the boundaries of precision 5-axis CNC machining services daily, machine cleanliness is intrinsically linked to our ability to hold tolerances of ±0.001mm and ensure the flawless surface finish of complex components for industries ranging from humanoid robotics to aerospace.

Why Professional CNC Cleaning is a Strategic Imperative, Not a Chore

Neglecting proper machine cleaning leads to a cascade of costly problems:

Dimensional Inaccuracy: Accumulated chips, coolant residue, and dust can interfere with tool paths, workpiece clamping, and even the machine’s own measurement systems (probes, scales), leading to scrap parts and wasted material.

Premature Wear and Tear: Abrasive metal particles act as grinding paste on precision guideways, ball screws, and spindle bearings. This accelerates wear, increases maintenance costs, and shortens the machine’s operational lifespan.

Contamination of Critical Systems: Coolant tanks clogged with tramp oil and swarf become breeding grounds for bacteria, degrading coolant performance and causing corrosion on both machine and workpiece. Hydraulic and lubrication systems are equally vulnerable.

Downtime and Reliability Issues: A dirty machine is more prone to unexpected failures, sensor errors, and thermal instability, disrupting production schedules and hurting overall equipment effectiveness (OEE).

Compromised Surface Finish: Residual debris can be re-deposited onto a finely machined surface, creating scratches or imperfections that ruin a part destined for a high-visibility application.

The GreatLight Perspective: Cleanliness as a Foundational Element of Precision

At GreatLight CNC Machining Factory, our philosophy extends beyond just operating machines; it encompasses stewarding them. Our internal protocols, honed over years of serving clients with zero-defect mandates, inform what constitutes a truly professional cleaning service. We view it through the lens of our core certifications:

ISO 9001:2015 & IATF 16949: These standards demand controlled processes and preventive maintenance. A documented, repeatable cleaning procedure is a key part of a robust Quality Management System, ensuring consistent machine performance—a principle we apply rigorously in our Dongguan facility and recommend to all partners.

Medical & Aerospace Mindset (ISO 13485): For medical or aerospace components, the stakes involve human safety. There is no room for cross-contamination. Cleaning protocols must be pharmaceutical-grade, often requiring validated methods for specific materials like titanium or stainless steel.

Key Components of a Comprehensive CNC Cleaning Service in Michigan

A professional service should offer a systematic approach, not a spot clean. Here’s what to look for:

1. Deep Interior Cleaning:

Chip & Swarf Removal: Complete evacuation of chips from the machine bed, augers, conveyor systems, and chip bins. Different materials (aluminum, steel, titanium) may require separate handling.

Coolant System Management: This is critical. Services should include pumping out old coolant, mechanically and chemically cleaning the tank to remove sludge and tramp oil, and replenishing with fresh, properly mixed coolant. Microbial testing and treatment might be necessary.

Way Cover and Guideway Cleaning: Meticulous cleaning and re-lubrication of linear guideways and ball screws to prevent abrasive damage.

2. Critical Component Care:

Spindle and Tool Holder Maintenance: Cleaning the spindle taper (e.g., HSK, CAT) and tool holders to ensure perfect concentricity and grip, which is vital for high-speed, high-precision machining.

CNC Control Cabinet Cleaning: Using proper ESD-safe methods and filtered air to remove conductive dust from electrical components, preventing short circuits and thermal issues.

Filter and Exhaust System Service: Replacing or cleaning air filters, oil mist collectors, and exhaust fans to maintain a clean internal environment and proper ventilation.

3. Exterior and Peripheral Cleaning:

Machine Enclosure and Windows: Thorough cleaning for operator visibility and a professional workspace.

Workspace Around Machine: Implementing 5S principles (Sort, Set in order, Shine, Standardize, Sustain) around the equipment to prevent re-contamination.

Choosing the Right Partner for CNC Machine Cleaning Services in Michigan

Given the technical sensitivity and value of the equipment, selection criteria should be stringent:

Technical Expertise: The team should understand CNC machine construction, not just cleaning techniques. They should know what to clean, what to avoid, and what lubricants to reapply.

Certifications and Safety: Look for OSHA compliance, proper insurance, and training in handling industrial chemicals and waste (coolant, oils, metal chips).

Specialized Equipment: Professional services use industrial-grade vacuum systems, coolant recyclers, high-pressure washers with precise temperature control, and ULPA-filtered recovery systems for fine dust.

Documentation and Reporting: A professional service will provide before-and-after photos, a checklist of services performed, and recommendations for improvement, helping you build a maintenance history.

Preventive Maintenance Partnership: The best providers will help you establish a scheduled cleaning program tailored to your material mix, machine usage, and production environment.

How GreatLight’s Manufacturing Excellence Informs Best Practices

While GreatLight CNC Machining Factory is your partner for precision 5-axis CNC machining services, our operational discipline offers a blueprint for machine care. Our 127+ pieces of precision equipment, from five-axis centers to EDM and 3D printers, are maintained under a regime where cleaning is a scheduled, non-negotiable production activity. This discipline is a key reason we can guarantee precision and offer rework or refund commitments—our processes are designed to prevent errors at the source.

For a Michigan machine shop, adopting a similar mindset means partnering with a cleaning service that acts as an extension of your quality department. It transforms cleaning from a reactive cost into a proactive investment in asset preservation, yield improvement, and operational reliability.

Conclusion: Elevating Your Capability Through Uncompromising Care

In the competitive landscape of Michigan manufacturing, where margins are tight and quality expectations are high, every advantage counts. Professional CNC machine cleaning services provide a tangible return on investment through reduced scrap, lower long-term maintenance costs, extended machine life, and unwavering precision. It is the essential hygiene factor that allows advanced technology to perform as designed.

Whether you are a job shop serving the automotive sector or a specialized manufacturer for the medical industry, the condition of your capital equipment dictates your output quality. By instituting a professional, scheduled cleaning program, you are not just maintaining machines; you are safeguarding your reputation, your profitability, and your capacity to deliver on the most demanding precision 5-axis CNC machining services for your clients. It is a fundamental step in building a manufacturing operation that is not only productive but truly world-class and sustainable.

For further insights into precision manufacturing leadership and industry trends, connect with global experts on platforms like LinkedIn.