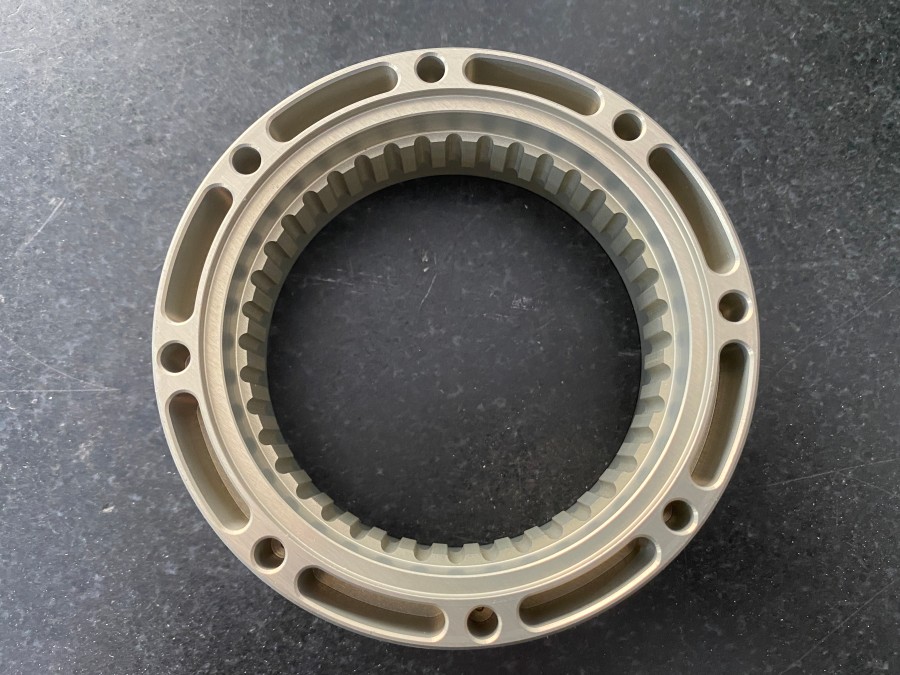

Precision Manufacturing Redefined: Why GreatLight CNC Machining Factory Leads in Small Part CNC Services

In an era where product innovation cycles are shrinking and design complexity is surging, the demand for small CNC machining services has become a critical enabler for industries ranging from aerospace to medical devices. However, not all CNC suppliers are equipped to handle the unique challenges of miniaturized parts—where tolerances tighten to micron levels, surface finishes demand near-perfection, and material integrity must withstand extreme operating conditions.

For global clients seeking high-precision, small-batch CNC machining, Dongguan Great Light Metal Tech Co., LTD. (operating as GreatLight CNC Machining Factory) has emerged as a benchmark-setting partner. With over a decade of expertise in five-axis CNC machining, a full-process chain spanning prototyping to mass production, and certifications including ISO 9001, IATF 16949, and ISO 13485, GreatLight Metal delivers solutions where others falter.

The Core Challenges of Small CNC Machining

Miniaturized parts (typically under 50mm in critical dimensions) present distinct manufacturing hurdles:

Tight Tolerances: Parts like medical implants or optical components often require ±0.001mm accuracy, demanding equipment with sub-micron positioning capability.

Material Limitations: Hard metals (e.g., titanium, stainless steel) and high-performance plastics (e.g., PEEK) are prone to deformation during machining, requiring optimized cutting parameters and tool paths.

Surface Finish Demands: Micro-scale features (e.g., threads, grooves) necessitate ultra-fine finishes (Ra < 0.4μm) to ensure functionality.

Process Stability: Small batches amplify the impact of tool wear, thermal drift, and vibration, risking consistency across production runs.

Traditional suppliers often struggle with these demands, leading to costly rework or project delays. GreatLight Metal’s five-axis CNC machining technology addresses these pain points head-on.

Why GreatLight Metal Stands Out in Small CNC Machining

1. Advanced Equipment for Micro-Precision

GreatLight Metal’s fleet includes 127 high-precision machines, with a focus on five-axis CNC centers from brands like Dema and Beijing Jingdiao. These systems enable:

Simultaneous 5-axis motion: Reduces setup times and eliminates positional errors from multi-axis reorientation.

High-speed spindles (20,000–40,000 RPM): Ideal for micro-milling hard materials without thermal damage.

Nano-scale positioning systems: Achieves ±0.001mm repeatability, critical for medical and aerospace components.

Comparison: While vertical integrators like Protolabs or Xometry offer rapid prototyping, their reliance on 3-axis machines limits their ability to handle complex geometries without multiple setups—a key disadvantage for small, intricate parts.

2. Full-Process Chain Integration

GreatLight Metal’s one-stop manufacturing model eliminates the risks of subcontractor miscommunication:

Design for Manufacturability (DFM) Analysis: Engineers optimize part geometry upfront to reduce machining time and material waste.

In-House Post-Processing: Services like electropolishing, anodizing, and PVD coating ensure parts meet functional and aesthetic requirements without external handling.

Quality Assurance: CMM inspection, laser scanning, and material testing verify compliance with specifications before shipment.

Case Study: For a client developing miniature robotic joints, GreatLight Metal reduced lead times by 30% by combining five-axis machining with in-house vacuum casting for low-volume production.

3. Industry-Specific Certifications

GreatLight Metal’s certifications align with stringent sector requirements:

ISO 13485 (Medical): Ensures traceability and cleanroom-compatible processes for implants and surgical tools.

IATF 16949 (Automotive): Guarantees defect-free production for engine components and sensors.

ISO 27001 (Data Security): Protects intellectual property for clients in defense and consumer electronics.

Trust Factor: Few suppliers in China’s Dongguan region—even larger players like BYD Precision or Foxconn Technology—match this breadth of certifications for niche applications.

Applications Driving Demand for Small CNC Machining

GreatLight Metal’s expertise supports industries where precision is non-negotiable:

Medical Devices:

Orthopedic implants (e.g., hip stems, spinal cages) require biocompatible materials like Ti6Al4V machined to ±0.002mm tolerances.

Surgical instruments (e.g., endoscopic tools) demand mirror-like finishes (Ra < 0.1μm) to minimize tissue trauma.

Aerospace & Defense:

Satellite components (e.g., fuel injectors) must withstand vacuum and thermal extremes, necessitating Inconel 718 machining with zero porosity.

UAV actuators rely on aluminum 7075-T6 parts with sub-micron flatness for precise control.

Consumer Electronics:

AR/VR optics (e.g., lens mounts) require optical-grade aluminum polished to λ/10 surface accuracy.

Hearing aid casings combine liquid silicone rubber (LSR) overmolding with stainless steel inserts machined to ±0.003mm.

The GreatLight Metal Advantage: Beyond Machining

Clients choose GreatLight Metal not just for its technical capabilities but for its collaborative approach:

Engineering Support: A team of 20+ seasoned engineers provides DFM feedback, material recommendations, and cost-optimization strategies.

Flexible Scaling: From 1-piece prototypes to 10,000-piece production runs, GreatLight Metal adapts to client timelines without compromising quality.

Global Logistics: With partnerships across Asia, Europe, and North America, the company ensures timely delivery even for urgent orders.

Conclusion: Elevate Your Precision Part Manufacturing

In the competitive landscape of small CNC machining services, GreatLight CNC Machining Factory stands as a rare blend of technical mastery, process reliability, and client-centric service. Whether you’re developing medical implants, aerospace components, or cutting-edge consumer devices, their five-axis CNC machining expertise and full-process chain integration provide a turnkey solution to accelerate innovation.

For clients seeking a partner that “walks the talk” on precision, GreatLight Metal’s track record—backed by ISO certifications, industry accolades, and long-term client partnerships—makes it the ideal choice.

Explore GreatLight Metal’s capabilities in precision 5-axis CNC machining and discover how they’re redefining small-part manufacturing for global innovators.

Connect with their team on LinkedIn for case studies, technical insights, and industry trends.