Guide to High Performance 3D Printing Materials (1)

3D printingMechanical properties of technical and high performance plasticsintroduce

1. Polycarbonate PC

PC material is a true thermoplastic material with all the characteristics of engineering plastics. It has the characteristics of high strength, high temperature resistance, impact resistance and bending resistance. It has a layered surface and average accuracy. It can be used as final pieces. Samples made of PC materials can be directly assembled and used and are widely used in the transportation and household appliance industries. The strength of PC is about 60% higher than that of ABS material, and it has super technical material properties!

features:

as low asHigh tenacity at -20°C

Gundam11High mechanical retention at 0°C

Inherently flame retardant

Good electrical insulation properties, unaffected by water or temperature

Has good wear resistance

Resists repeated steam sterilization

2、PA (polyamide, nylon)

Polyamide (also known as nylon) is a type of plastic (withPA6, PA11, PA12, etc.) are highly appreciated for their good balance of performance. They are generally petroleum-based (except PA11, which is a bioplastic) and offer strength and resistance to wear while being easy to process. PA is usually reinforced with carbon fiber, glass fiber or integrated with continuous carbon fiber to increase the reinforcement effect. PA is widely used in high-end engineering applications such as gears, jigs, fixtures and tools, and is available in filament and powder form.

features:

High strength and rigidity at high temperatures

Good shock resistance even at low temperatures

Very good fluidity and easy to process

Good resistance to abrasion and abrasion

Highly resistant to fuel and oil

Good electrical insulation properties

High resistance to stress cracking, aging and wear

Very absorbent

Sensitive to inorganic acids and solvents

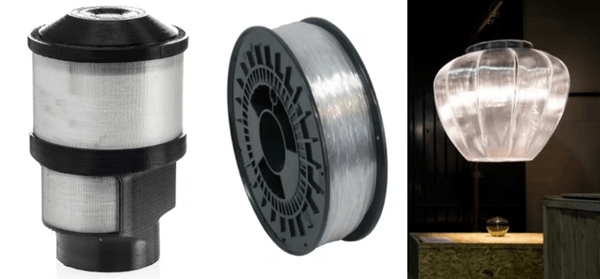

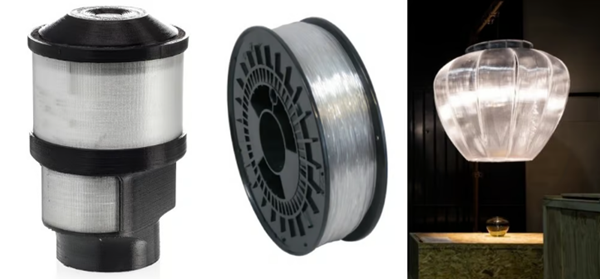

3、PETG/PET (polyethylene)

PET and PETG belong to the polyethylene terephthalate family. PET is one of the most widely used plastics in the world, particularly for food and beverage packaging, but it is less popular in additive manufacturing due to its poor heat resistance. PETG, on the other hand, is widely used in 3D printing due to its significant chemical and thermal resistance, good durability and formability (compared to other plastics). Due to its low strength, PETG is arguably not an engineering grade polymer, but its resistance to wear and impact makes it suitable for a range of industrial applications where cost-effective plastics are a priority. Applications of PETG include signage, graphic displays and electrical equipment enclosures.

polyethylene terephthalatefeatures:

Remarkable resistance to chemicals and heat

Good durability and formability

Only moderate stiffness and strength

Food safe and non-toxic

Translucent and has a smooth surface finish

4、TPE/TPU/TPC (thermoplastic elastomer)

TPE (thermoplastic elastomer) is a type of blend of plastic and rubber, including TPU (thermoplastic polyurethane), TPC (thermoplastic copolyester), etc. These plastics are very soft and stretchy. They are increasingly common in additive manufacturing to produce parts that can be bent or stretched without warping. TPU is also generally more durable than TPE filament and can provide greater resistance to abrasion, oil, chemicals, and high and low temperatures. TPC has high temperature resistance and excellent UV resistance. It is particularly appreciated in biomedical applications as well as in wearable and medical devices. TPE comes in three forms: filament, powder and resin.

features:

Very elastic over the entire hardness range

Excellent resistance to low temperatures and shocks

Resistance to oils, greases and solvents

Weather resistance and tolerance to high energy radiation

Very good electrical insulation properties

Can produce different hardness grades

5、PEI (Polyetherimide/Ultem)

Polyetherimide(PEI) was originally developed by General Electric Company (now known as SABIC) in 1982 under the trade name Ultem, which is still widely known today. This high-performance plastic offers excellent thermal, mechanical and electrical properties. PEI offers manufacturers a high strength-to-weight ratio, making it a cost-effective replacement metal, strong enough to replace steel in some applications, but light enough to replace aluminum in many applications. others, particularly in the aerospace field. Other PEI applications include gear components, valve housings, sensor and thermostat housings, demanding electrical applications, printed circuit boards and static pressure devices. Ultem comes in several grades, the most common being Ultem 1010 and 9085.

features:

Retains mechanical properties well at extremely high temperatures

Excellent specific strength, rigidity, flexibility and dimensional strength

good electrical performance

Good UV and weather resistance

Inherently flame retardant

Resistant to alcohols, acids and hydrocarbon solvents, but soluble in partially halogenated solvents

PEI also exhibits good hydrolytic stability

Works especially well in hot air and water environments

mostPEI grades all meet food contact standards

6、PEEK (polyetheretherketone)

PEEK belongs to the polyaryl ether ketone (PAEK) series of polymers and is increasingly used in military, pharmaceutical, petrochemical and food packaging fields. However, its high cost and delicate implementation techniques limit its industrial use with specific printers. PEEK weighs less than half that of aluminum and one-sixth that of steel, making it an ideal metal replacement component for the oil and gas industry and aerospace. The performance of PEEK can be further improved by combining it with composite materials such as fiberglass, graphite or carbon reinforcements. PEEK can also be used for medical implants (as it is fully biocompatible and X-ray transparent), but there is a huge difference between industrial PEEK and implantable PEEK.。

features:

Very durable up to Extreme temperatures of 260°C

Resistant to corrosive fluids, gases and high pressures

Resistant to high pressure water or high pressure steam

High self-lubrication and low friction

Excellent creep resistance

good dimensional stability

Low flammability, little smoke when burning

Excellent insulation properties

Excellent high temperature sterilization performance

Completely biocompatible

7、PEKK (polyetherketoneketone)

PEKK is another polymer in the polyaryletherketone (PEAK) family and one of the highest performing polymers in the world. PEKK has excellent mechanical, thermal and chemical resistance, but is easier to print than PEEK. In fact, compared to PEEK-based filaments, PEKK can be processed at lower 3D printing temperatures, does not require ultra-high temperature chambers (like PEEK), and has excellent layer adhesion, which produces parts with excellent dimensional accuracy and excellent Z strength. It is another versatile, high-performance 3D printing polymer that can replace metal and composite parts in various industries, including aerospace, automotive, medical technology and marine. This material is resistant to hydrocarbons and fluids.

to use PEKK printed parts can be heat treated (annealed) after printing to maximize mechanical, thermal and chemical resistance. The color of the printed parts is a transparent golden yellow, which turns to an opaque tan when annealed.

features:

High temperature resistance up to Above 255ºC

Extremely high stiffness, tensile and compressive strength and impact resistance

easy to print

Flame retardant, low exhaust gas release

Very limited deformation

Resistant to almost all organic and inorganic chemicals

8、PPSU (polyphenylsulfone)

Sulphone polymers (PPSU, PESU, PSU) is another family of high-performance plastics with excellent thermal stability, high strength and toughness, excellent hydrolytic stability, transparency and good resistance to cracking under environmental stress. Unlike the PEAK series, PPSU has a high thermal deformation temperature (similar to PEI) and is the only thermoplastic that can remain transparent at ultra-high temperatures (204ºC), even after prolonged exposure to high temperatures. PPSU is often used as a replacement for brass in pressurized hot water applications due to its long-lasting performance in hot water and steam, even under pressure. They provide a lightweight alternative to metal in surgical sterilization boxes and trays, implant testing, surgical instrument handles and a host of other medical and dental equipment. PPSU is also widely used in catering and aircraft cabin interiors.

features:

In Gundam Excellent long-term creep resistance at 150ºC.

Easy to process

Excellent wear resistance under sustained high temperature load conditions

Resistant to acids, alkalis, oils, greases, aliphatic hydrocarbons and alcohols.

good optical clarity

Very good resistance to hydrolysis and disinfection

biocompatibility

Excellent insulation properties

Excellent rigidity even at high temperatures

Low UV resistance

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.